Anjou invests in Bobst Digital Master 340

Built-in calibration and quality control module with Bobst Accucheck was selling point for Anjou

Anjou invests in Bobst Digital Master 340

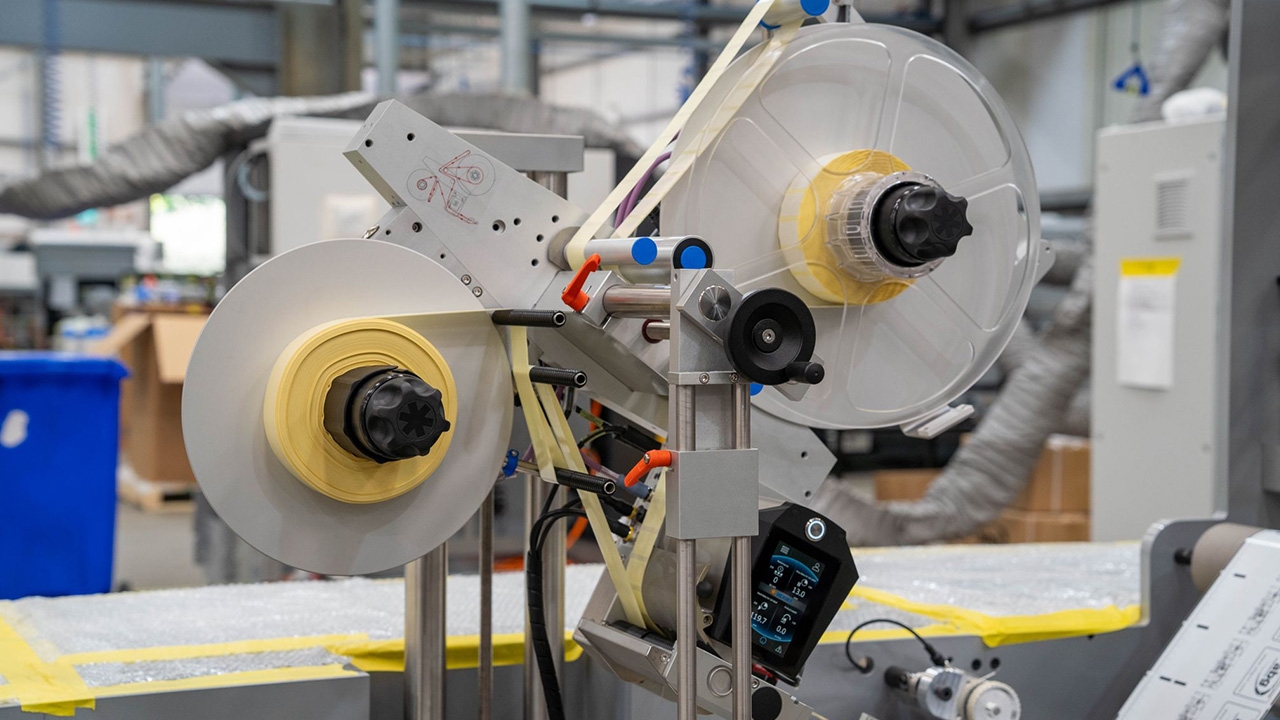

Anjou Etiquettes, a family-owned label converter located in Montreuil Bellay, in the Maine-et-Loire department in France, has invested in a new Bobst Digital Master 340 to help simplify its label production.

From simple monochrome labels to colorful multilayer labels, it is crucial to deliver quality at every stage of the production process including variable data and all in a short period of time. Labels are ubiquitous, but many of them require intricate production processes to meet the expectations of brand owners.

‘The Bobst Digital Master 340 is the ideal solution for the current challenges,’ said Laurent Bossy, co-manager of the company along with Sabrina Chardonneau. ‘The machine effortlessly handles print runs ranging from 1,000 to 15,000 linear meters or more. We run the press every day, and I must say I'm impressed by its print quality and speed. We can achieve a resolution of 1200x1200 dpi at a speed of 100m/min.’

The new press can incorporate new modules, such as a varnishing unit or a semi-rotary die-cutting module, all designed and supplied by Bobst. The modularity and on-site upgradability of the Digital Master 340 are major advantages for converters, allowing them to safeguard their initial investment and grow at their own pace.

A significant advantage of the Digital Master 340 for Anjou is the built-in calibration and quality control module – Bobst Accucheck. It takes care of everything, from head calibration and alignment to registration and 100 percent inspection of the printed web.

‘Inspecting all of our labels ensures that we deliver the highest quality to our customers, and we maintain an average production waste of just 2 percent,’ Bossy said.

The decision to partner with Bobst was based on shared company values – professionalism and authenticity.

‘We chose Bobst for their true essence of partnership and professionalism of their teams,’ said Bossy. The Digital Master 340 was delivered, installed, and operational in less than a week. The service team trained all the employees, adapting to their capabilities. ‘The ramp-up process was seamless, without any pressure. The new press integrated straight into our facilities and processes.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.