Vietnamese converter boosts productivity with Martin Automatic MBS

Vietnamese converter Agricultural Printing & Packaging has installed Martin Automatic splicing technology to a Gallus EM 410 in order to streamline the production of tobacco packaging.

Agricultural Printing & Packaging manages the production of 500 million cigarette packs a year, and the 20,000 tonnes of paperboard required to produce them. Agricultural Printing & Packaging supplies its packaging products to the domestic Vietnamese market, and is also developing a healthy export trade. The company also manufactures self-adhesive labels for the food, confectionery and pharmaceutical industries, as well as supplying aluminum, PVC and BOPP to the converting market. Outside of printing, it has interests in estate management.

The company operates offset, gravure and flexo presses, as well as offering die-cutting, folding and gluing, and other carton finishing processes. However, manual roll changing on its Gallus narrow web press was causing a bottleneck in the production of cartons, resulting in the company looking to automation to ensure reliable and efficient operation of the EM 410 press line.

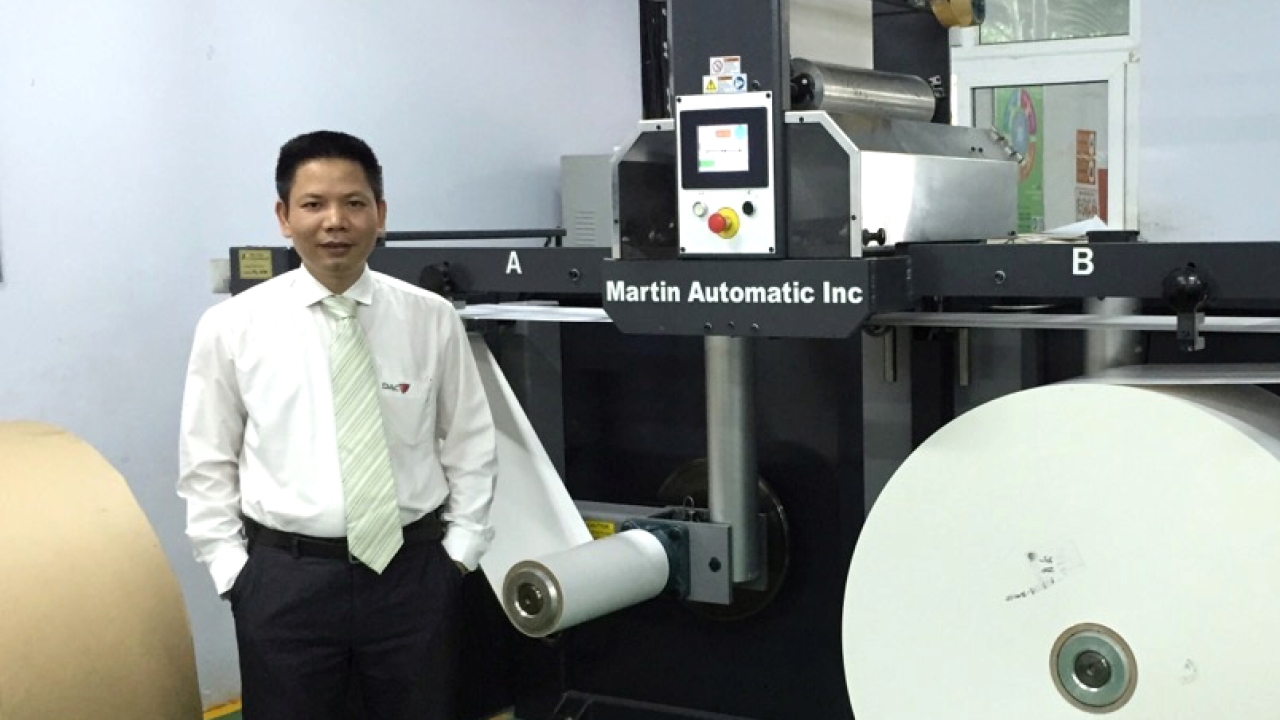

This resulted in a Martin Automatic MBS automated unwind butt splicer being retrofitted in-line with the Gallus press in July 2014. So successful was the installation at improving productivity that in September that year a second Gallus EM 410 press was purchased, fitted with a Martin Automatic MBS at installation.

Le Duy Toan, deputy director general for Agricultural Printing & Packaging, said: ‘We run the Gallus presses 24/7 and make around 30 roll changes per day. This used to take six minutes each and wasted 50 metres of material every time, when we did it manually. With the Martin automatic splicers we have seen productivity increase by 10 percent, or to put it another way, we get more than two hours extra production in every 24 – that’s an excellent return on our investment.’

Agricultural Printing & Packaging is planning further investments in 2016, including in flexible packaging production and a new factory.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.