Avery Dennison releases new atma.io features

Spring ‘24 new features eliminate handling errors before they impact the downstream supply chain.

Avery Dennison has introduced new features to its atma.io connected product cloud that will help reduce handling errors across the supply chain, create significant operational efficiency, and eliminate chargebacks.

The new features, part of the Spring ‘24 release, will help factories and brands achieve shipping accuracy and timely, transparent order fulfillment while increasing efficiency in factory processes, the company reported. It will provide brands with accurate traceability data that will also help them prepare for Digital Product Passports (DPPs) and other use cases by ensuring all items are correctly tagged at source and accurately shipped to the distribution centers (DCs).

Among the new features, Factory Dashboard for Scan & Pack enables factories to ship accurate stock and cut down on chargebacks – a new consolidated view of the scan and pack tool that allows factories to validate the content of packed cartons against the packing plan to ensure packing accuracy. By providing real-time visibility of purchase order status and completion, the dashboard feature helps factories deliver accurate shipments that lead to accurate inventory in the downstream supply chain, minimizing the risk of chargebacks, according to Avery Dennison.

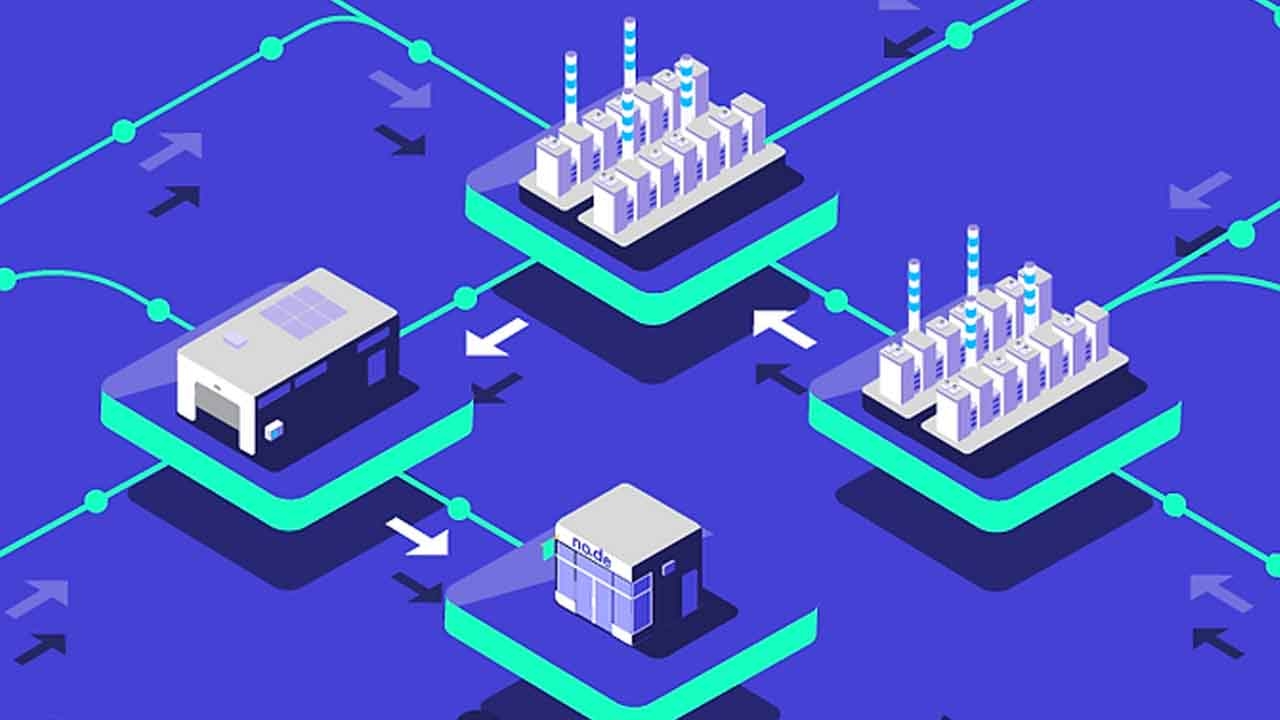

Supply Chain Map enables organizations to visualize their entire supply chain – this harnesses the power of the atma.io connected product cloud to visualize all the events recorded throughout the supply chain in an interactive, concise, and easy to understand way. By easily seeing how goods have traveled through the supply chain, organizations can pinpoint errors and inefficiencies.

GS1 compliant logistic labels can now be generated directly through atma.io – GS1 labels provide a common language that allows businesses to identify, capture, and share information the same way worldwide. atma.io generated labels can be applied to shipping units to uniquely identify the exact unit carton or pallet to provide all relevant information needed to identify the unit and the goods it carries by all actors in the logistics chain. In parallel, atma.io forwards the shipment information digitally to the receiver in a standardized ASN (advanced shipping notice) message. This captures the event data necessary for traceability use cases.

Michael Goller, senior global director for atma.io at Avery Dennison, explained: ‘The idea is to fix as many issues at source as possible to improve operational efficiency further downstream . Managing 30+ billion items has given us unparalleled insights across the different nodes in the supply chain. As products flow through the supply chain, inaccuracies and errors accumulate, triggering significantly more expensive handling further downstream. For example, a significant number of products reaching Distribution Centers show issues in terms of tagging/labeling or completeness. Fixing these issues before they leave the factory can save up to three times more time further up the supply chain. But it's more than just time. Incorrect information can give organizations false item-level data and impact decision making. It can leave retailers short of the stock they need and be a barrier when adopting Digital Product Passports. There’s an overwhelming case for resolving any issues as quickly as possible.’

Other notable features of the atma.io Spring ‘24 release include; a replenishment report that calculates the replenishment needs of every sales floor location based on the target and available quantity; and an inventory reconciliation report that compares the stock and points out products that should not be in inventory as well as the ones that are missing from it.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.