Skanem Interlabels Nairobi enhances quality, sustainability

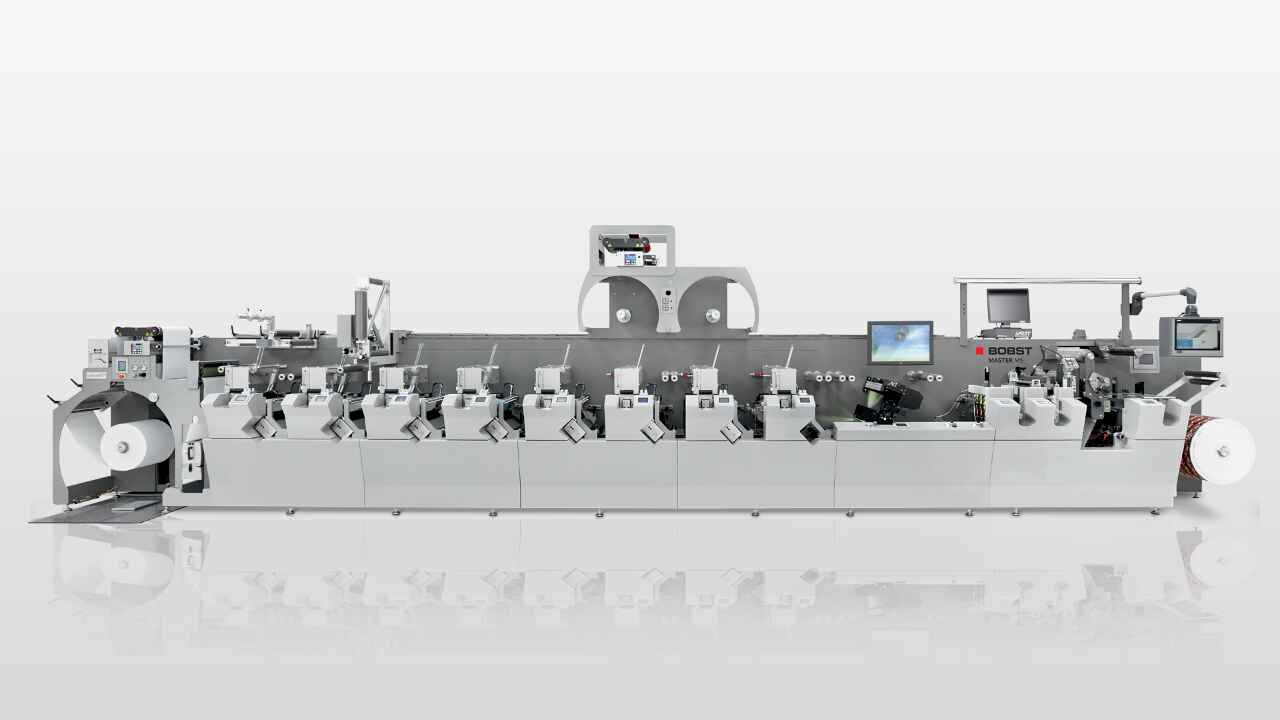

Find out why the Bobst Master M5 is the machine of choice for the leading multinational label provider when it comes to sustainable flexo printing.

Skanem Interlabels Nairobi, one of the leading multinational label converters, has taken a significant step forward in enhancing its production capabilities in Nairobi, Kenya, with the installation of a new Bobst Master M5 machine. The decision to install the Bobst Master M5 is part of Skanem’s broader vision to be a leader in label manufacturing by investing in technologies that deliver superior products and meet the evolving needs of its clients.

‘Today, Skanem labels are seen on millions of products every day and pretty much everywhere whether you are at home, office or at a grocery store. We create labels to help brands make their products look beautiful, stay secure, share information with end users and at the same time be kind to the environment,’ says Sachen Gudka, managing director of Skanem Interlabels Nairobi. ‘But it wasn’t always the same.’

History

It was 1905 in Norway. The thriving canned fish industry in the Stavanger region, with over 60 canning factories, presented a lucrative opportunity for three enterprising individuals: Albert L Barstad, Halfdan Abel Lunde and Robert Paul Richard Scholz. They seized this chance and established a tin can manufacturing company, Stavanger Bliktrykkeri og Maskinverksted.

The company’s journey was marked by both triumphs and challenges, culminating in its rebranding as Skanem in 1973 under the ownership of the French packaging conglomerate, Cebal. A subsequent acquisition by an Oslo-based investor group led to the appointment of Ole Rugland as the new managing director.

In 2003, Rugland astutely observed that the market for metal packaging was nearing saturation. He made the strategic decision to invest in the burgeoning segment of the packaging industry: self-adhesive labels. This marked the beginning of Skanem’s ascent as one of the leading multinational label providers.

The company’s expansion continued in 2012 with the acquisition of Interlabels in India and Africa. This strategic move granted Skanem entry into the African market and solidified its presence in the region. The synergy between Skanem’s global expertise and Interlabels’ local knowledge and experience positioned the company as a formidable force in the African label industry.

‘At Skanem Interlabels Nairobi, our people are our most important asset. Today, we have over 400 employees, serving a diverse clientele in the beverage, food, personal care, household maintenance, pharmaceutical, automotive and industrial packaging sectors, across 13 countries in Africa,’ says Gudka. ‘This is a testament to our belief that when people thrive, the business flourishes.’

We create labels to help brands make their products look beautiful, stay secure, share information with end users and at the same time be kind to the environment

However, the company recognizes that a trusted technology partner is essential to accelerate its growth journey, which is firmly rooted in three pillars—quality, sustainability and efficiency.

Love thy quality

‘For us, everything revolves around quality,’ emphasizes Gudka. ‘Our customers rightly demand excellence, and we strive to provide them with the finest labels available on the market. And, Bobst is the only name that comes to mind when we talk about quality.’

The proof?

Skanem Interlabels’ journey with Bobst (Gidue at the time) began in 2011-12 when it installed an M1 10-color press with a 370mm web width. Since then, Bobst has been the company’s technology partner. Twelve years and three Bobst machines later, when the time came for further expansion, Skanem again chose Bobst. This time, the company invested in the Bobst Master M5 in-line UV flexo press, which was installed at its Nairobi facility in December 2023.

‘With the Master M5, we can confidently deliver exactly what our customers want: quality,’ shares Gudka.

The Master M5 is ideal for converters seeking to automate their production lines

This advanced press is designed for rapid job changeovers, minimal waste and reduced downtime, which are crucial factors for a busy label converter like Skanem. Its integration of digital control and flexo technology ensures that every print run, regardless of size, meets the highest quality standards while maintaining cost efficiency.

Eric Pavone, business director of the web-fed business unit at Bobst in Africa, Middle East and Turkey, emphasizes: ‘Skanem’s top priority is ensuring the highest quality labels. The Master M5 shines on this front, delivering exceptional consistency at remarkably low operating costs while catering to a diverse range of substrates, including adhesive labels, pressure-sensitive labels, BOPP wraparound labels, shrink sleeves and in-mold labels.’

Championing sustainability

Sustainability is another cornerstone of Skanem’s strategy. The company is committed to fostering growth for its customers by providing sustainable labels and packaging options. The decision to install the Bobst Master M5 was driven by its ability to enhance efficiency while promoting sustainability.

As businesses worldwide seek to reduce their environmental footprint, the Master M5’s low-waste production and energy-efficient operations align with Skanem’s green initiatives.

Gudka comments: ‘Our aim is to create sustainable growth for our customers. The Master M5 aligns perfectly with this goal by minimizing downtime and waste, which are crucial factors in today’s evolving markets. This press empowers us to reduce waste while maintaining top-notch quality, making it a win-win for both our customers and the environment.’

With the Master M5, Skanem can achieve faster production times while significantly reducing material waste, ink usage and energy consumption. This focus on sustainability not only meets the growing demand for eco-friendly products and technologies but also supports Kenya’s national goals of promoting green industrialization.

The key features of the machine that skewed Skanem’s decision toward it include high-speed printing (up to 200m/min) and rapid setup times, allowing multiple print jobs to be completed within a single shift.

Also, the machine can produce labels for a variety of applications, from self-adhesive to shrink-sleeve and in-mold labels as well as flexible packaging.

There’s also an option to equip the machine with oneECG technology, which digitalizes color matching with an extended 7-color gamut.

Digital workflows with integrated printing and converting technologies, such as DigiFlexo auto-registration with the PrintTutor intelligent camera system, help reduce operating costs and maximize machine uptime.

These capabilities have enabled Skanem Interlabels Nairobi to significantly increase its output, effectively meeting the growing demand for labels in the Kenyan market.

In this context, Gudka emphasizes: ‘Since installing the Master M5, we’ve witnessed substantial improvements in our production workflow.

‘With the current trends in packaging, shorter runs and a proliferation of SKUs are becoming commonplace. This is where the Master M5’s ease of use, reliability, and speed are crucial factors that enable us to meet tight deadlines and exceed customer expectations.’

Future outlook

The installation of the Bobst Master M5 at Skanem Interlabels Nairobi marks a significant milestone not only for the company, but also for the broader African label printing industry. As the continent continues its industrialization and modernization, investments in advanced machinery and technology are crucial for fostering economic growth and global competitiveness.

Skanem’s strategic decision to upgrade its capabilities reflects a growing trend in the African manufacturing sector, where businesses are increasingly prioritizing efficiency, quality and sustainability. By staying at the forefront of technological innovation, companies like Skanem are instrumental in elevating Africa’s position as one of the key players in the global supply chain for high-quality label production.

Moreover, with more international companies seeking to source their labeling and packaging needs from African manufacturers, Skanem is ideally positioned to capitalize on this growing demand.

With the installation of the Bobst Master M5, the company is looking to increase its market share in Kenya and neighboring countries, while developing strategic partnerships with regional businesses. It also aims to expand its customer base across various industries.

Gudka adds: ‘This investment underscores our unwavering commitment to delivering top-notch labels, meeting the evolving demands of our customers and expanding our presence in the East African market.’

The installation of the Bobst Master M5 at Skanem Interlabels Nairobi is more than just a machinery upgrade; it’s a strategic move toward Industry 4.0, where automation, data exchange and smart manufacturing systems define the future of production. This investment positions Skanem at the cutting edge of the label printing industry, empowering the company to confidently and innovatively navigate the challenges of the future.

By incorporating this technology into its operations, Skanem Interlabels Nairobi is not only strengthening its position as a market leader but also contributing to a more sustainable and prosperous future for the African label industry.

Skanem’s expansion continues in Africa

Skanem Africa has launched a new labeling factory in Dar es Salaam, Tanzania, aiming to enhance service delivery and expand market reach within the East African region. Officially operational since late July 2024, this new plant brings Skanem closer to its existing customers and opens the door to fresh market opportunities. The Tanzanian facility complements Skanem’s existing operations in Kenya, focusing on increasing production capacity, boosting output and significantly reducing lead times. By establishing a local manufacturing base, Skanem aims to provide more efficient service to its clients while attracting new business in the region. Located in the commercial hub of Dar es Salaam, the factory is strategically positioned to serve markets in seven East African countries: Democratic Republic of Congo, Kenya, Malawi, Mozambique, Tanzania, Zambia and Zimbabwe. This expansion marks a significant milestone in Skanem Africa’s regional growth. The facility is equipped to produce self-adhesive labels, BOPP wrap-around labels and shrink sleeves, ensuring high-quality labeling options for businesses in Tanzania and beyond.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.