RY Label diversifies for growth

Utilizing a skillful mixture of conventional and digital print and finishing equipment and emphasizing quality has kept RY ahead in a competitive market. Yolanda Wang reports

RY Label diversifies for growth

RY Label was founded in Shanghai in 2008. In 2019, its new factory in Zhejiang Province was completed, and the company moved its production base out of Shanghai. Today the company has 70 employees and daily label production capacity is more than 200,000sqm.

In 2022, the annual output value of RY Label reached more than 50M RMB ($7.2M USD). RY Label is a comprehensive label solution provider, integrating design, printing and post-press processing. Its key end-user markets include tire, logistics, electronics, automobile, steel, clothing, retail and household chemicals.

History and development Men Yan’an, founder and general manager of RY Label, has been in the label printing industry for more than 20 years. In 2002, he graduated from the Beijing Institute of Graphic Communication and joined Shanghai Tobacco Industrial Printing Company (later renamed Shanghai Tobacco Packaging Printing Co., Ltd.), where he was responsible for technology and research. Then he joined UPM Raflatac and was responsible for the sales of special label materials. Later, he joined a domestic company as executive vice president. With this background of professional knowledge and years of working experience, Men Yan‘an had a good understanding of the label printing industry and its market requirements.

With an optimistic outlook on the future development potential of label products, he was prompted to start his own business. In 2008, Men Yan’an registered Shanghai RY Label, with an initial workshop area of 1,500 sqm. With the company growing rapidly, he set up a new operation in Qingdao, Shandong Province in 2012. In 2017, Men Yan’an began to build a new plant in Jiaxing, Zhejiang Province.

On November 18, 2019, the Jiaxing factory was completed with a total investment worth 50 million RMB ($7.2M USD) ‘With the growth of Shanghai RY Label’s business, the existing leased plant was not able to meet the company’s production and development needs,’ says Men Yan’an. ‘The label printing business is an asset-heavy processing industry. Especially for printing equipment, certain requirements need to be met. We believed that investing in a wholly-owned plant would be good for our future planning, development and layout, in terms of plant structure, decoration and other aspects.’

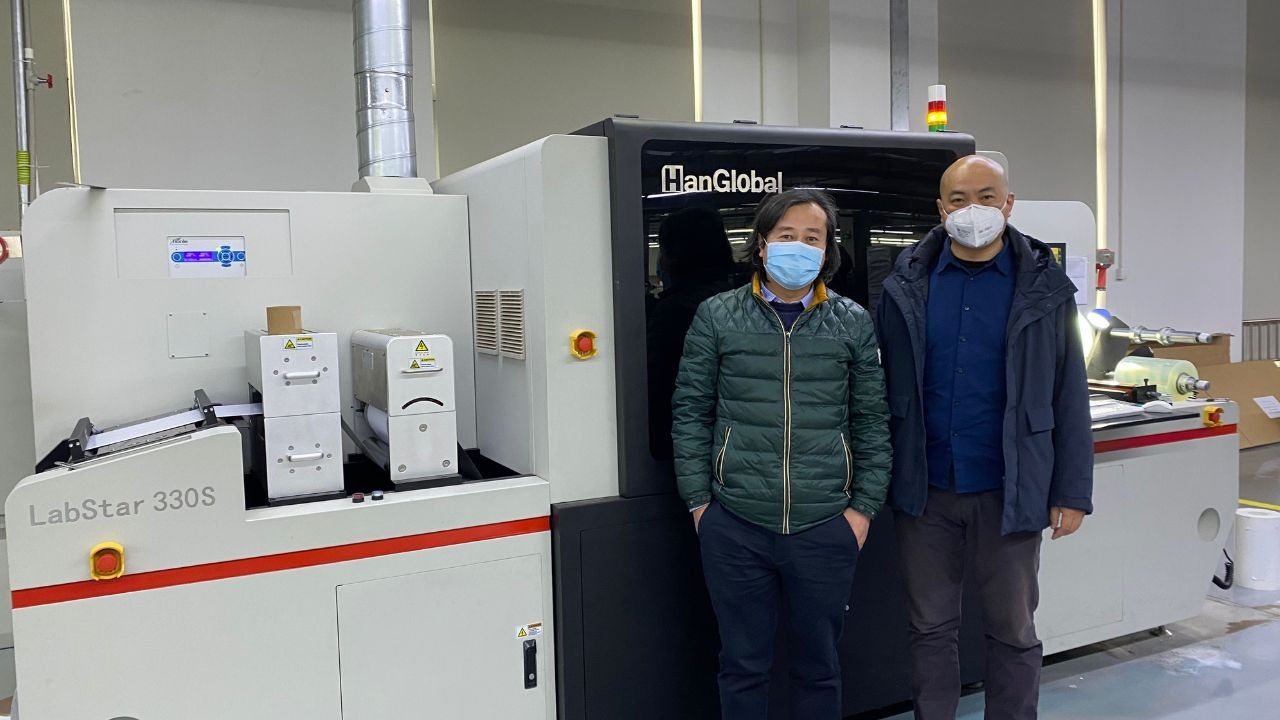

All the production equipment from the Shanghai factory has now been transferred to this new factory, including a Mark Andy flexo press, Lintec letterpress and HP Indigo 4500 digital press. In addition, the company has invested in a Weigang inline flexo press, HanGlobal LabStar 330S inkjet press, Reborn digital die cutting equipment, Rhyguan die cutting machine and other equipment.

‘Every year, 20 percent of the company’s sales revenue is used in R&D and new equipment investment, to ensure that our company’s production capacity and technical skills are ready to meet the changing needs of the market,’ Men Yan’an says. In addition to its internal R&D personnel, RY Label also actively cooperates with professional industry R&D institutions and constantly improves its ability to provide multi-process label products.

The company has successively patented inventions including a high-speed web adjustment device for a digital printing press, and a flow control device.

Time to diversify

The increasingly fierce competition and excess capacity in the label printing industry has been particularly evident in the past three years since the outbreak of Covid-19. For label converters, it is more necessary than ever to diversity.

‘Label products used in tires, automobiles and electrical appliances, account for a large part in our business, Men Yan’an comments. ‘Such labels usually have multi-SKUs and the number is generally not large, which makes them very suitable for digital printing technology. This is the main reason why we continue to invest in digital presses.’

Interestingly, more new orders are coming to RY Label from its industry peers. Such orders usually have special requirements in process, design and labeling. That means it takes more time to communicate with customers, and multiple proofing passes before confirmation for production.

RY Label is gradually transferring such orders to its digital press and laser die-cutting equipment to improve efficiency. RY Label makes a clear distinction: ‘Conventional printing technology has advantages in production efficiency and cost for long-run orders, and the printing quality is more acceptable to customers. We use this printing equipment to produce products with large runs and relatively simple process requirements. Compared to personalized and special label orders, these orders still have the largest market share.’

In addition to traditional label products, RY Label also invested in a Hadesheng laminating machine and data writing system to produce RFID, NFC and other intelligent label products.

Quality is key RY Label has insisted on providing high-quality products and services since its inception. The company has established a strict and standardized quality management and control system covering all production chains from design to delivery.

‘My experience has taught me that quality is of primary importance to brands,’ Men Yan‘an says. ‘Label products, in particular, are not only an important part of the packaging of goods but also a key bridge for brands to communicate with customers.’

In addition to continuous investment in equipment and technology, RY Label also organizes regular internal staff training. RY Label has passed ISO9001, ISO14001 and ISO45001 management system certificates in recent years. High-quality products and services attract a group of loyal customers for RY Label. To date, they have serviced more than 1,000 brand customers, including some well-known brands such as Zara, Goodyear, Hankook, Pernod Ricard, Sam’s Club, Unilever, Lion, Panasonic and Philips.

The future

After the epidemic, there will be new trends in the end-user consumer market, as well as some new development opportunities.

‘I think, some difficulties caused by Covid-19, such as raw material shortages, logistics constraints, staffing shortages, will ease slightly in 2023, but consumers’ concerns about health and environmental sustainability will continue to affect how they choose goods and services. People will be more inclined to choose goods and services with high quality and market recognition that they trust. This is bound to affect the label products,’ says Men Yan’an.

Thanks to the reputation it has built up over the years, RY Label achieved an impressive 45 percent sales growth in 2022. The question now is how to further expand the company’s orders, and improve the efficiency of their existing equipment.

These will be the main goals in 2023. The company is very confident it can double the growth of business profits in the coming year.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.