★You are viewing this content as a subscriber

★Subscribers only

Factors affecting surface treatment and ink adhesion

The main film substrates used for labels have differences in mechanical properties but also in how they can successfully be printed

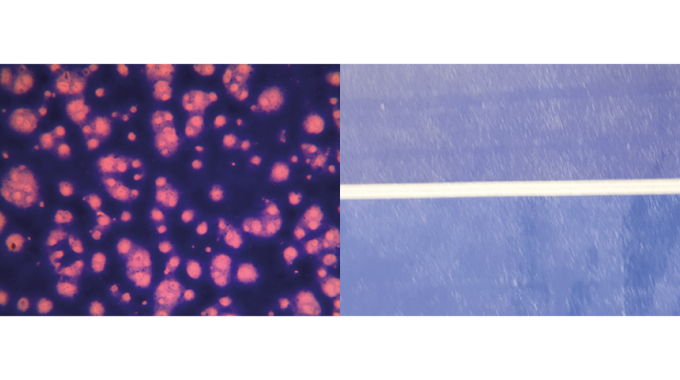

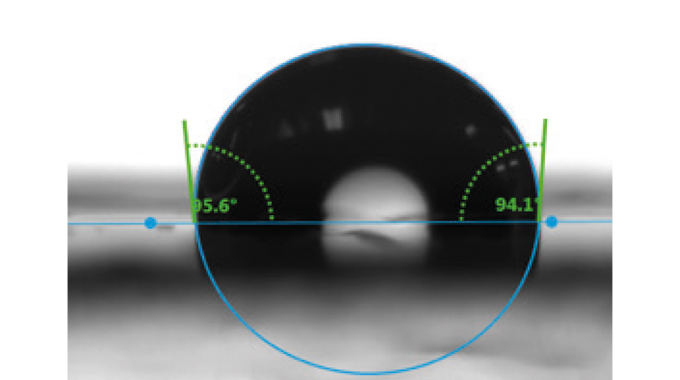

Many factors affect the adhesion of ink to a filmic label surface, and one of the most important is the surface coating. This impacts both the visual appearance and the physical performance of the print. In most cases, manufacturers have to prioritize certain properties and also make compromizes when developing a top coating for label face material.

Properties that are expected from a substrate include:

- Accurate control of dot size (area and ink film thickness)

- Consistent density in compact printed colors

- Good adhesion between ink and substrate

- Non-blocking (top coating against reverse side of the liner material in the reel)

- Resistance to all kind of environmental stress depending on the use for the label

- Consistent performance of the substrate with time

- Preferably universal performance and not specific for a print method or a specific use

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.