drupa 2016 label and package printing preview

drupa 2016 takes place May 31 to June 10 in Düsseldorf, Germany, and will host around 1,600 exhibitors spread across 19 halls. Some 300,000 international visitors are expected across the 11 days of the show.

The below supports and extends the drupa 2016 preview that was published in L&L issue 2, 2016, and can be read online here.

adphos | Alphasonics | Amica Systems | AMS | Apex | Asia Pulp & Paper | Atlas Converting Equipment | AVT | Cerutti | Comexi | Cosmo Films | Creative Edge Software | DuPont | Durst | Eagle Systems | FFEI | Flint Group | GEW | Goss | H.C. Moog | Highcon | HP Indigo | Kama | Komori | Landa | LasX Industries | Lombardi | Masterwork | Memjet | MGI | Michelman | Mitsubishi HiTec Paper | Miyakoshi | OKI Europe | Omet | Pasaco Coated Papers | QuadTech | Sandon Global | Selectra | Soma | ThermoFlexX | Toyo Ink | Troika | Univacco | W. H. Leary | Xeikon | Zeon |

Hall 6, stand C3

Highlight applications where adphosNIR technology has enabled drying, curing and thermal processing at high speeds, including drying of water-based adhesives for packaging at 305m/min (1,000f/min) and sintering of conductive inks for printed electronics at 152m/min (500/min).

Hall 10, stand B16

Launches Anilox Control as the new standard for its anilox cleaning equipment, and to showcase developments described as the ‘answer to the flexographic cleaning problem’ with brand new parts and plate washing systems. This launch is the culmination of months of development which encompass new approaches and new features.

Alongside this, following the launch of Active Cavitation at Labelexpo Europe 2015, a new technology which alternates between varying ultrasonic frequencies in one cleaning cycle is shown.

Hall 6, stand A17

Shows new inkjet systems, including the Amica LR54 roll-to-roll narrow web printing system and LPS330 all-in-one full color system, and NuviINK GUA2 family of water-based pigment inks for a variety of industrial applications. Read more about Amica Systems and its updated inkjet offering here.

Hall 14, stand 71

Introduces MultiWave LED-UV blended wavelength LED module featuring a uniform blend of wide spectrum UV and LED wavelengths at equivalent power levels, and with a performance range designed for compatibility with many existing UV photoinitiator packages, including low-migration formulas. The development means that the ink prices for LED curing can now be similar to those of existing high quality UV inks.

Also shows a new low-profile LED module, XD, for easy conversion of space-restricted machines to LED printing, and X-Air, high power air-cooled UV LED modules.

Hall 11, stand B26

Presents several new concepts for multiple print disciplines, including: fixed palette printing (4C and 7C), where its GTT anilox rolls have been designed to create the most consistent and controlled laydown in the industry which is especially important for optimized fixed palette printing; printing with water-based inks printed on to foil and film; and smooth coating transfer technology for the coating, digital and offset industries.

The Apex stand serves as a knowledge center for printers that come across issues such as opaque white, ghosting and spitting, while its equipment features in live demonstrations at several machine manufacturers.

Apex also hosts a fixed palette congress on June 2, together with leading suppliers and brand owners.

Hall 4, stand F8

Shows updated and established product lines for the print and packaging industry, including: SinarKraft multilayer packaging board range, a three-ply product consisting of pure bleached hardwood kraft fibers with an inner unbleached kraft fiber layer; Extraprint wood-free uncoated graphical papers, available in a range of formats and grammages; Zenith fully coated folding boxboard with a coated white back (GC1), designed for luxury cosmetics, confectionary, high-quality packaging, greeting card and pharmaceutical applications; and Nevia Plus coated wood-free papers.

Hall 12, stand 12

Presents range of primary and secondary slitter rewinders as well as demonstrating the latest generation of the Titan SR800.

Hall 9, stand C60

Introduces a set of next-generation products and technologies, including: a new cloud-based quality standards and automation platform; digital press inspection and control; in-line color management; and several new inspection platforms for web- and sheet-fed packaging applications.

Showcases include: iCenter Platform, a next-generation cloud-based tool for quality control automation and production performance insights; the latest version of Offline Setup; SpectraLab II, a new generation of in-line spectral measurement for nearly any application, including transparent flexible, paper and cartons; Argus Turbo and Helios Turbo 100 percent Inspection platforms for label and packaging applications; Apollo 30K for HP Indigo folding carton presses and Titan for the metal sector; and 100 percent inspection and workflow for HP Indigo label and packaging presses, 100 percent inspection for inkjet label presses and the Jet-IQ closed loop quality engine press control for digital inkjet presses.

Hall 16, stand B3

Shows two versions of its R98X gravure press, one for shafted and one for hollow printing cylinders locked by air chuck, and the entry-level R1081 model. Also showcases its work to integrate inkjet into its gravure press lies and laminating equipment, which you can read more about here in an exclusive Q&A.

Hall 10, stand B20

Presents a new version of its F1 flexo press featuring an integrated robot to directly handle all the steps involved in the printing process and optimizing production with more efficient switching of work gears, which can increase production by more than 20 percent it is claimed. It also increases the printing of custom work by 30 percent due to the efficiency gains it brings to production.

Offset CI8, which was launched at drupa 2012, on show alongside the R2 gravure press. A Nexus L20000 laminator shown on the HP Indigo stand alongside an HP Indigo 20000 digital press for flexible packaging. A Nexus L20000 has recently been installed at HP Spain, as detaild here.

Also debuts Comexi Cloud, a tool for the development of smart factories. The production control tool allows factories to see and understand their data and process it consistently to facilitate optimal decision making.

Hall 3, stand A31

Introduces a new range of premium lamination films under the Luxotique brand, comprising velvet, scuff-free matte and digital lamination films. Also showcases its standard and special application lamination films. read more about its new premium range of lamination films here.

Hall 7, stand C16

Shows new packaging design capabilities with the release of its iC3D v4, which incorporates a number of features for 3D photorealism. With iC3D v4, five new features have been developed, including: ray tracing, which accurately simulates effects of light on virtual objects for photorealistic, ultra-high-resolution, accurate photo studio effects; 3D model interiors, which enable realistic liquid filling, at any angle; light map editor, which recreates studio lighting, editable highlights and shadows; dynamic backgrounds, offering real-time merging of 2D photo images with 3D designs; and perspective control, which matches 3D model perspective to 2D photo backgrounds. These new features allow accurate simulation of a wide range of optical and visual effects.

iC3D v4 replaces the need for professional photography for marketing or promotional materials, and packaging designs can be created from scratch and then immediately printed as true photographic image content on boxes, advertisements, posters, web sites and proofed or printed on 3D printers.

Read more about iC3D v4 here.

Hall 8b, stand C21

Highlights Cyrel Easy flexographic printing plate technology and its newest equipment offering. Cyrel Easy simplifies the pre-press process by building the flat top digital dot directly into the plate, resulting in increased productivity and consistency. Other technologies featured include: Cyrel Fast 2000 TD, Artistri digital inks, Tyvek packaging technology and the new Izon anti-counterfeit technology, which is detailed here.

Hall 6 at D40

Presents the Tau 330 in combination with a laser finishing system (LFS), and provides information about the new Tau 330E standalone model which, with a pigment ink system, offers cost-effective access to digital production, according to Durst.

Also shows the new Rho 130 SPC with a print speed of up to 9,350 sq m an hour, offering the industrial productivity needed to transform the packaging sector towards digital technology. Alongside more cost-efficient production of shelving and sales packaging in small and medium job runs, the Rho 130 SPC supports sampling, customizations and versioning. A non-hazardous ink system based on Durst Water technology addresses future directives for sustainable packaging products in the food retail sector. The Rho 130 SPC is based on the latest generation of single-pass printing systems which Durst is already using in the label printing segment, such as with the Tau 330.

Of further interest is the Rho 1330 flatbed printing system which, with its extensive media flexibility and high level of automation, is particularly aimed at traditional offset printing providers.

Hall 16, stand A71

Shows sheet-fed cold foiling on uncoated paper, an industry first and the result of six years of R&D. Read more about the development here.

Hall 10, stand B16

Presents end-to-end digital inkjet consultancy services to expand the use of digital inkjet technology through. FFEI managing director Andy Cook and a team of digital inkjet experts at the show to discuss real-world application opportunities for inkjet and to answer questions on the Graphium product range.

FFEI's product portfolio includes Graphium Label Workflow, RealPro Workflow System, RealPro Toolkit, RealPro ColourCloud, RealVue3D Packager, RealVue3D Publisher and Alinte violet CTP range.

Halls 3, 8a and 8b

Has three distinct spaces at the exhibition, with an information booth in hall 3, a pre-press orientated stand in hall 8b, shared with ThermoFlexX, and a main location in hall 8b highlighting the combination of Flint Group and Xeikon.

Showcases ‘One team, One Future, One Flint Group’ concept with a vast range of inks, coatings, pressroom chemicals, flexographic plates and equipment, mounting sleeves, printing blankets and print services and options, plus the new Digital Printing Solutions division created following the acquisition of Xeikon.

Hall 12, stand A28

GEW launches the NUVA2 UV system for wide web applications, available in widths up to 2.5m from a single lamp. NUVA2 is a fully air-cooled UV system for web or sheet-fed applications in the printing, coating and converting industries. The active air cooling and optically tuned reflectors maximize lamp curing effect while reducing heat radiation onto the substrate.

NUVA2 systems can at a later stage easily be upgraded to LED operation. An arc lamp cassette and an LED cassette can be operated interchangeably and seamlessly on the same print unit using the same Rhino ArcLED electronic power supply, control panel and cabling – the only tool needed is an Allen key.

GEW also unveils its Multipoint in-line UV dose control, which allows comprehensive monitoring of the UV output during the curing process. It acts as a built-in UV intensity meter and measures the actual intensity across the full width of the lamp. Low intensity which would not adequately cure is thus avoided, as is insufficient output from a degraded lamp.

GEW’s third launch is an inert atmosphere UV curing system, used principally in the production of silicone release liners and direct food contact packaging, with the curing process takes place under controlled conditions in a sealed nitrogen chamber.

GEW’s inert atmosphere curing system can be supplied as an add-on or as a retrofit and comes with an embedded oxygen level analyser to ensure process consistency and production efficiency.

Hall 15, stand D51

Highlights its packaging, commercial and newspaper press portfolio, including the Sunday Vpak platform, and the latest Contiweb technologies. Contiweb is renowned for the supply of splicers and dryers to web offset printers, however there have been recent developments for digital web printing, as detailed here. Examples from the Contiweb digital unwinder and rewinder series will be running on a number of booths at drupa 2016.

Further, under the theme ‘Achieving more together’, demonstrates how bringing complementary brands and technologies together is a way to support Goss customers and prospects considering investments in new products and services.

Hall 3, stand A35

Presents its sheet-fed gravure technology, as recently installed by Indian printer Pragati Pack. Read more more about its investment in a 1-TBR Compact multi-functional press here.

Hall 9, stand C50

Introduces portolio of products, incluyding Beam, Pulse, Euclid III and Axis software as part of a strategic move to further the reach and capability of its technology, which you can read more about here. The UK's Glossop Cartons has installed the world's first Beam, as detailed here.

Hall 17, stand A1

Presents an array of label and package printing technologies, including the new HP Indigo 8000, as detailed here, and developments with its 20000 and 30000 digital press platforms. This includes developments from partners such as Comexi and Tresu and prorietary develoents like Pack Ready, a lamination system built to the same format as the 20000 flexible packaging press, for the production of high-performance applications such as retort pouches. Unique to this system is zero curing time lamination, and HP Indigo has developed a resin which allows a laminating film to form an instant and strong bond with the Indigo-printed substrate using nip pressure and heat.

Hall 2, stand A15

Presents world premiere of FF52i folder gluer and DC 76 ASB automatic die-cutting machine , which when combined are said to optimize job and format changes, and fit into a digital workflow to carry out all the applications from the printed sheet to the ready-to-deliver folding box.

With extremely short set-up times, faster finishing, inline stripping without tools and automated set-up, the solution paves the way for making short-run converting of folding boxes both efficient and profitable.

Hall 15, stand D4

drupa 2016 marks the start of general availability of the Impremia IS29 UV inkjet printing system. Impremia IS29 is a state of the art inkjet printing system capable of printing on a wide range of stocks. By taking advantage of UV inkjet characteristics, this system is ideal for not only commercial print applications, but also package printing.

Also demonstrated is the B1 Impremia NS40 digital printing system that uses nanotechnology under license from Landa. This press performs high-speed printing at 6,500sph and is the world’s first B1 inkjet printing system.

Lithrone GX40RP, Lithrone GX40 with coater and the new Lithrone G29 29inch offset printing press also on show.

Hall 9, stand A73

Introduces Nano-Metallography technology that offers zero waste metallization and reduces costs by more than half compared to standard foil transfer. It will be shown on an Omet XFlex X6 press on the Landa stand.

Shows Landa W10 Nanographic Printing Press for flexible packaging, a meter-wide (41in) web press that prints up to 8 colors at 200m/min (656ft/min) on plastic packaging films, paper, carton board and aluminum foil. Sheet-fed presses running at 13,000 B1 sheets per hour also shown.

Hall 11, stand E17

Demos CartonsInMinutes system which converts printed materials to finished cartons in less than a minute versus traditional processes taking days, weeks or even months to complete. In addition to high speed throughput, CartonsInMinutes reduces cost by eliminating costly tooling and set-up, and reducing or eliminating WIP inventories. Read more about CartonsInMinutes here.

Hall 4, stand F53

Shows 8-color Synchroline 430 with new semi-rotary device for special applications such as hot foil stamping and creasing for carton boxes.

Hall 1, stand 1

Presents automatic sheet inspection machines, die-cutting and embossing tools and folder gluers for folding cartons and packaging. Demonstrations include the new Duopress 106FCSB that offers six processes in one pass: foil stamping, embossing, die-cutting, stripping, blank separation and product collection. The Diana Eye 55 fully-automatic sheet inspection system and modular Diana Smart 55/115 folding carton gluing machines shown too.

Masterwork has also combined its R&D focus and its manufacturing capabilities with Heidelberg’s support network, and at drupa both firms are displaying the Promatrix 106 CSB die-cutting machine with blanking for short to medium production volumes and able to perform die-cutting and embossing at a speed of 8,000sph. Easymatrix 106 CS die-cutting machine with stripping rated at 7,700sph also on show.

Hall 5, stand C24

Demonstrates on its stand high-speed digital color printing technology through systems built by OEM partners, including Xanté, Colordyne, Delphax, Digikett and Astro Machine. Other Memjet OEM providers such as Canon-Océ, Trojanlabel, Afinia, New Solution and Xerox will are showing Memjet’s technology in action on their own stands.

Hall 5, stand D21

Shows JETvarnish 3DW digital embellishment press for web-fed labels and folding cartons. JETvarnish 3DW was introduced last year at Labelexpo Europe 2015, as detailed here. Also shows AlphaJet B1+ sheet-fed UV inkjet press with a sheet size capability of up to 75 x 120cm (29.5 x 47in). It prints using 4- to 8-color UV technology, and can apply 2D/3D spot UV coating and embossed hot foiling special effects. One of the advanced technology options provides a dedicated production option for intelligent printing (such as RFID antennas). This module uses conductive ink jointly developed with Agfa.

Hall 4, stand A24

Shows new primer technology for use with high speed water-based inkjet printing presses, which creates opportunities for equipment manufacturers and owners. Read more about this development here.

Hall 8b, stand D24

Shows papers designed for various digital printing technologies and applications for labels and packaging, including Supercote, Thermoscript and Jetscript products, and launches Giroform Digital One for All.

Hall 9, stand A22

Presents MLP-H, which is said to be the fastest semi-rotary UV wet offset press for labels. MLP-H provides a printing speed for semi-rotary press at 121m/min, due to the combination of a running speed of 300 impressions per minute with a repeat length of 406.4mm(16in). This high productivity makes MLP-H suitable for short to mid runs for labels and matches flexo/letterpress press productivity.

Miyakoshi says MLP-H is a replacement model for flexo/letterpress users who are facing tighter profits due to shorter job lots. Producing labels in offset quality provides an option to win new jobs that require higher printing quality. The press is also suited for semi-rotary offset users who are looking for higher productivity to take on longer job lots. Miyakoshi’s calculation based on its customer shows that MLP-H provides lower running cost compare to flexo/letterpress up to 30,000m. Optional units include screen and hot foil stamping.

MLP-H is available in 350mm and 420mm web widths, with 330mm and 406mm print width. It can handle a substrate range from 70-300 micron. Read more about MLP-H here.

Hall 5, stand B21

Spotlights the new Pro6410 NeonColor printer, which enables the printing of super-bright, fluorescent designs on transfer media for use in multiple applications, from garment and product decoration, to personalization, packaging, point-of-sale and in-store signage.

In addition to the Pro6410 NeonColor, OKI Europe showcases white toner printers Pro7411WT and Pro9420WT, together with the Pro9541 and Pro9542 5 color printers.

Hall 3, stand D90

Debuts Varyflex V2 Offset 850 as the Italian press manufacturer makes a definitive move into package printing. Read more about the new press here, and read an exclusive Q&A on Omet's strategic move into package printing here. An XFlex X6 features on the Landa stand.

Hall 4, stand D21

Promotes silicone papers and linerless label products. Read more about the European coated paper manufacturer's recent expansion into the Middle East here.

Hall 15, stand D50

Debuts four products, including: a color quality product for packaging and converting that will allow press operators to collect and process color measurements, and facilitate the correction of ink formulations; a defect detection product for packaging and converting that facilitates fast detection and disposition of the tiniest defects; a color measurement product for packaging and converting that provides accurate in-line L*a*b* measurements, so reducing make-ready time and ensures all printed products are within your customer’s color specifications; and a color-to-color register product for newspaper printers that will simplify operation and provide a high quality, low-cost solution.

Also hosts the Print Performance Speaker Series, which includes presentations from: Peter Kloppers, of DG press ServiceS, on web offset as an alternative to flexo/gravure for flexible packaging; David Galton, of Asahi Photoproducts, on fixed color palette printing; Bruno Mortara, of Alwan Color Expertise, on the commercial advantages of expanded gamut printing strategies; Paul Barnes, of GMG Color, on brand color management and Cxf in a packaging workflow; Rico Hagedorn, of Flint Group, on flexo plating technology; Carol Werlé, of Dalim Software, on innovations in packaging; Thomas Strohe, of Flint Group, on the latest trends in ink technologies for flexible packaging; Dr Joerg Pohé, of Hell Gravure Systems, on engraving technologies ; James Siever, of the European Rotogravure Association, on the gravure packaging market in Europe; plus others throughout the 11 days of drupa 2016.

Hall 15, stand B34

As well as featuring its well established HVP and iProanilox technology, presents Fluid anilox roll technology. Launched at the end of last year, and detailed here, this technology consists of a semi-channelled engraving that allows an easier yet controlled flow of ink between cells. Fluid is available for bespoke, flexible packaging, corrugated and narrow web applications.

The robust cell formation of Fluid enables increased line counts, offering enhanced HD print quality and dot control whilst providing vivid HD highlights. Fluid has the advantage of combining vignette and solid print on one plate, in contrast to conventional 60 degree engravings only capable of offering either a high volume or high line count, but not both. The greater print latitude offered by Fluid means anilox inventories can be reduced by increasing line counts and maintaining high volumes of ink thus improving press efficiency by reducing anilox changeovers.

The open nature of the cells also facilitates cleaning of the anilox helping to maintain consistency by improving color matching. Further, Sandon Global said the Fluid cell format enables ink to transfer more effectively increasing the lifespan of the anilox by maintaining optical density for longer.

The resut This new Fluid cell engraving combines to resolve or eliminate printing issues such as pin-holing, ink spitting, ink starvation and scoring contributing to new levels of consistency, color and print quality comparable to gravure or offset.

Hall 10, stand E60

Presents new web guide system Seleguide 10K equipped with a compact touchscreen operator panel for an effective and user-friendly interface. System allows more precise alignment of the reels avoiding waste of material and significantly improving the quality of the final product. A further development is the introduction of remote panels able to manage the operation of the instrument by means of Modbus communication (RS485) or Profinet (Ethernet) even at very large distances.

Visitors also able to see the new in-line viscosity system Selevisco 9000, specifically engineered for controlling flexographic and rotogravure inks or glues. The measuring unit, based on vibrating technology, is installed directly on the supplying pipeline.

Hall 15, stand A1

Launches Optima2, a wide web version of the Optima short run CI flexo press, and available in 1050mm and 1270mm widths.

Available in 620mm and 820mm widths in up to eight colors, the mid web Optima is capable of speeds up to 300m/min and features unwind and rewind systems that are located outside the printing unit modules. This variable design allows the option of choosing any unwind/rewind configuration and in-line upstream or downstream printing and converting units such as cold seal or slitting. Soma says the press bridges the gap between narrow and wide web printing for products such as in-mold and wraparound labels, shrink sleeves, retort pouches and sachets as well as paper sacks, cups and plates. An Optima was demonstrated at Labelexpo Europe 2015.

The Optima2 has five unique options for flexo printing, including the Advanced Bounce Control system which has been developed by Soma to allow difficult designs to be printed at optimum speeds.

Demonstrations will take place throughout the show.

Hall 8b, stand D12

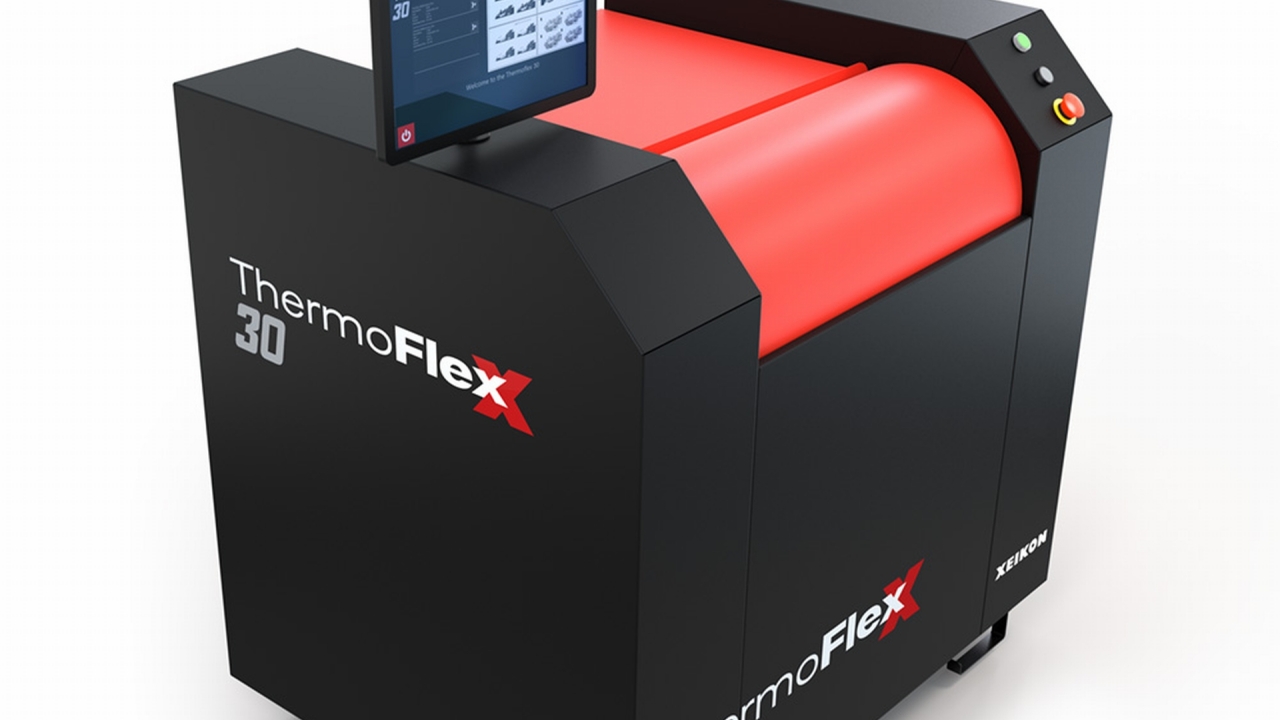

ThermoFlexX launches several major additions to its product portfolio, including the completely redesigned ThermoFlexX 20 and ThermoFlexX 30 digital flexo plate imagers. Dual-head ThermoFlexX 80-D demonstrated with a new pixel-stitching functionality, plus a ThermoFlexX 48-S in-line with an Evo 3 LED exposing unit. Other equipment will include a basysPrint 861x-B CTP system for conventional UV plates. Co-exhibiting with Flint Group Flexographic Products following the takeover of Xeikon by Flint Group.

Hall 4, stand B39

Toyo Ink, Toyo Ink Arets and Toyo Morton co-exhibit and show a wide range of printing and packaging options designed to help brand owners and package printers reduce wastage throughout the supply chain, lesson environmental risks, enhance food safety and achieve uniform packaging quality worldwide.

This includes products for flexo printing, UV/EB curable printing, retort pouch production and eco-friendly water-based systems. Flash Dry FL Kaleido UV-curable flexo inks, Lioflex Aqua Liona NFQD flexo inks, Steraplast Food and Steracup Plus, and Steraflex UV flexo inks for label and narrow web applications are on show. Steraflex Food has been formulated to support food label printers and packaging converters achieve desired print performance results, as detailed here.

Toyo-Morton shows solvent- and water-based laminating adhesives for packaging applications.

Hall 10, stand C13

Shows Advanced Inspection Microscope (AIM), a fast, accurate and simple to operate 2D microscope that can work in conjunction with different applications within the print industry. AIM can be used with Troika’s Advance Gravure Analysis (AVA) and Advance FlexoPlate Analysis (APA) applications. The AIM 2D microscope and its applications serve as replacement for the older DOS and Windows 95 microscopes and systems, which many gravure engravers and printers are currently using. For flexo plates, the 2D APA application gives greater in-depth analysis of flexo plates for dot size, dimensions, relief depth and plate condition analysis.”

Also shows further improvements to FlexoPlate QC and Anilox Management System (AMS) for the Anilox QC system, and CorruCAM, a tool that is able to measure aniloxes within corrugated presses.

Hall 3, stand F1

Cooperates with Gietz to feature the FSA 870 Compact hot-stamping and die-cutting press on which an attractive poster will be finished with hot-stamping foils for visitors to see and take with them. The FSA 870 Compact is used in the print finishing of folded boxes, for example in food and non-food applications, as well as in the print finishing of printed matter , including labels.

Univacco also presents its new range of multi-purpose graphic pigment foils that can be applied on a wide variety of substrates and are available in a range of colors.

Another highlight is the new Truly Seamless Rainbow Sheetfed cold foil. This type of holographic cold foil has a very high gloss level and no disturbing shim lines visible. It can be applied in combination with a large variety of conventional oxidative drying cold foil adhesives, printing inks and varnishes.

Univacco also launches an improved version of the UV-overprintable hot stamping foil OF-06. OF-06 allows the combination of large solids and fine details in a single run.

Hall 6, stand D62

New product launches include LearyVIEW vision detection with full carton inspection, carton serialization and iQ data collection with remote, web-based support. Product demonstrations will include 1D, 2D and Delta E color detection, hot melt application and detection, and insert application and detection.

W.H. Leary exhibits alongside global alliance partner Robatech.

Hall 8a, B20

Launches new flatbed die-cutting unit for the folding carton market, as detailed here, and shows Fusion concept for fully digital production of high-end, value-added label production. Also debuts Trillium One, a new liquid toner digital press, and new pre-press technology from Basys and ThermoFlexX, including the X20 and X30 for the labels and packaging market. Presence shared with new parent company, Flint Group.

Hall 3, stand C92

Presents portfolio of specialty elastomers for the printing and paper industries, including Hydrin T3108XL and Zeoforte ZSC. Printing rollers, roller coverings, printing blankets, conveyer belts, machinery belts and gaskets are the typical final products.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.