Labelexpo Europe 2023 – press technology

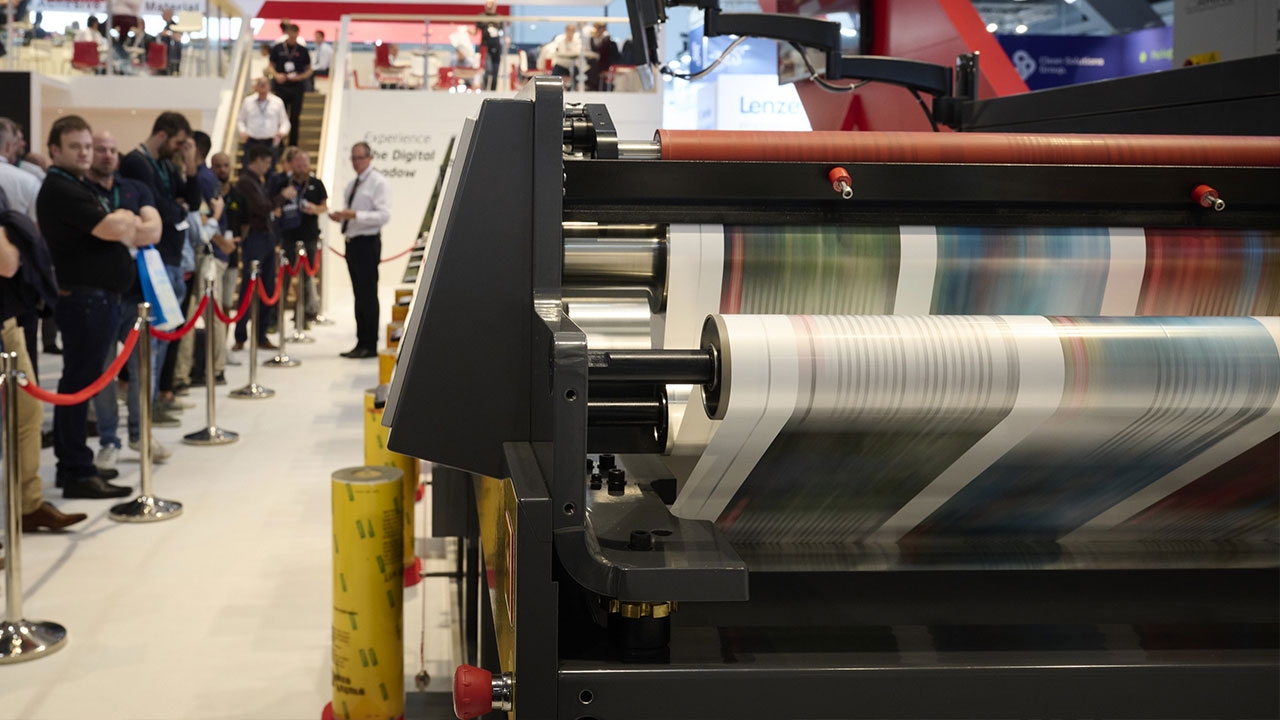

It was a fantastic sight to see so much state‐of‐the‐art flexo press technology at Labelexpo Europe 2023 after all the talk about the ‘death of flexo’ after Labelexpo Americas last year.

It was not only the presses themselves but also the surrounding eco‐system of more sustainable plate production, new anilox engravings and screening technologies, quick‐change rotary and semi‐rotary dies and extended color gamut inking systems, all of which continue to make the flexo process more efficient and sustainable.

The most easily visible trend was towards wider presses in the mid‐web sweet spot of 26in/670mm. This is wide enough to handle the larger formats required for shrink sleeves, flexible packaging and in‐mold labels.

Bobst demonstrated its Master M6 with a full automation package. These include on‐the‐fly exchange of printing cylinders and automated print pressure and registration setting and monitoring through the print run.

Combined with Bobst’s oneECG 7‐color extended color gamut system (more on ECG below), the press was shown changing between jobs in around one minute with a minimum of waste.

The press also incorporated GEW’s mUVm inline UV measurement system which measures lamp output close to the web surface continuously throughout the print run. Bobst calls this ‘UV track’, a feature for certifying UV as safe for food packaging. Bobst has been closely involved with the UVFoodSafe project run by Finat, whose initial results were presented by Sun Chemical’s Jonathan Sexton at the show.

Matteo Cardinotti, head of narrow mid‐web printing & converting and CEO of Bobst Firenze, believes these presses will make an impact, not only in the flexpack market but in the commodity label markets where automation is the key to profitable production, while more bespoke value‐added applications will increasingly migrate to hybrid digital/flexo press systems.

Nilpeter showed for the first time its FA‐26 mid‐web press, selling three at the show and garnering a number of firm leads. The FA‐26 prints at speeds up to 250m/min and was equipped with GEW’s LeoLED water‐cooled LED‐UV lamp systems.

‘I call this the Swiss Army Knife of short‐run added value flexible packaging,’ says Nilpeter’s Jakob Landberg. ‘It is worth remembering that what is a short run for a flexible packaging converter of 15,000 meters, is a really great longer run for a label converter.’

The high levels of automation present on these mid‐web machines cut down on the number of operators required. ‘The only thing that is conventional about these presses is we use plates and anilox,’ says Landberg. ‘They are more like robot systems that can be run from any point of the press by a single operator.’

Lombardi demonstrated a fully automated 11‐color Invicta i1 mid‐web press fitted with cold foil and multi‐layer booklet facilities and a Lynex‐S 100 percent inspection camera.

The company also previewed its new Invicta i2 and announced the sale through distributor Vinsak of an 870mm‐wide i2 to Prakash Printers and Coaters in India. A 670mm‐wide Invicta i1 press was sold to MGN at the show.

Nicola Lombardi, Lombardi’s marketing manager, said the Invicta presses were mainly being used for flexible packaging applications – including aluminum lids and thermal‐sensitive materials ‐ and shrink sleeve applications rather than PS labels because they allow converters to innovate in these markets, with most machines going to India or Asia.

NARROW WEB FLEXO

Turning to the more standard width narrow web flexo presses, it seems fair to say that flexo technology has reached a technological peak. The emphasis at this show was more on increasing efficiency through automation and the integration of various forms of digital print and embellishment modules to develop new forms of hybrid press systems. We also saw a raft of increasingly sophisticated flexo presses from manufacturers located outside Europe and the US.

Mark Andy introduced its Pro Series flexo press, which is field upgradable to a hybrid with the addition of the 5‐color toner module seen on the company’s DPro Max press. The press is designed to run both L‐R and R‐L to allow for this new configuration. The Pro Series is fully modular, allowing the press to be broken at any point to insert the digital unit.

Phil Baldwin, European sales manager for Mark Andy, says the Pro Series was designed as an entry‐level fully servo‐driven alternative to shaft‐driven presses. ‘For the smaller guys, it is no longer possible to be competitive on shaft‐driven machines. We are talking here about a 50‐70 percent reduction in waste over a mechanically‐driven press. At the same time, the Pro Series can give the larger converter more capacity.’

Nilpeter also showed a 17in FA‐17 press alongside its FA‐26 with a high‐build digital varnish unit as a replacement for rotary screen or flexo spot varnish and doming. The unit can be retrofitted at any point on the Nilpeter press.

Lombardi also demonstrated a 430mm‐wide Synchroline 430 in a configuration with rotary screen and digital embellishment modules. The press was sold to Italian converter Eticpress.

Omet showed the latest version of its KFlex modular UV flexo press platform. New features included the Swing semi‐rotary die‐cutting unit, allowing die‐cutting using a single magnetic cylinder for all label sizes and formats and with automatic plate loading and ejection.

Two new rail‐mounted units were shown on the press – the Jet‐Bar module for inkjet printing of raised varnishes, and the Cold Foil Saver unit, which enables standard foil application with a 50 percent reduction in raw material usage.

Chinese suppliers are starting to make a significant impact in flexo export markets following a strategic shift from intermittent offset to inline flexo press manufacture. Weigang displayed its sleeve‐based 450mm‐wide ZJR inline flexo press equipped with chill rolls for handling extensible films. The press runs at up to 180m/min and was configured with delam/relam.

Label Source launched its YTP‐F6 inline flexo press at the show, configured with chill drum and automated unwind and rewind. The press arrives with an automation package including auto registration with data saving and recall. The press was configured with a second pass scanner for re‐registration work.

Hontec has diversified from converting machinery to its first fully‐fledged flexo press, the 350mm‐wide fully servo‐driven Ultimate Series.

This sleeve‐based press is designed to handle a wide range of materials from PS to shrink sleeve labels. The press features pre‐registration and a short web path to minimize waste. Printing at up to 150m/min, the press was configured with cold foil, delam/relam and turn bar.

India has also produced some high‐flying flexo press manufacturers now putting their machines in front of a global audience.

In addition to Multitec, AKO was demonstrating its Delta‐series inline flexo press, fitted with horizontal die‐cutting station and liquid‐cooled ink chambers. The press is configured for a wide range of unsupported materials as well as PS labels.

Intermittent flexo was an emerging trend at this show, sold to converters as an alternative to digital printing while being able to use existing flexo plates.

Iwasaki launched its 5‐color IF‐330 intermittent flexo press including optional automatic registration system. The web width is 330mm and the repeat length variable between 50 and 320mm. Malaysia‐based Sen Labels Machinery showed its Sen IF‐350 intermittent flexo press configured with six colors and a cold foil unit and with LED‐UV curing throughout.

OFFSET THRIVES

Although there were no rotary offset presses on the show floor, the technology was represented by units from DG Press and Comexi. DG Press showed a print unit from its new variable sleeve‐based DG‐Auxo web offset press, available in print widths of 520mm, 900mm and 1085mm.

Comexi displayed a central impression (CI) drum from its CI‐8 offset press, which is dedicated to short‐ to medium‐run production of flexible packaging and unsupported film labels.

There was a particularly strong showing of intermittent offset presses from Chinese press suppliers, who are securing niche markets in the short run, high value‐added wine and cosmetics sectors in particular, where they are marketed as an alternative to digital.

Wanjie demonstrated its WJPS machine equipped with remote inking, LED‐UV curing and electronic register control, while Weigang showed its ZX intermittent offset press configured with flexo coating, embossing/hot stamping and die‐cutting (the usual configuration of these machines is with off‐line die‐cutting).

Zonten demonstrated its 340mm‐wide Multiprint intermittent offset press configured with pre‐register tension control and an automation package including pressure adjustment, inking roll washup and roller impression and semi‐automatic plate change.

Nickel exhibited its strikingly designed LED‐UV curing FS350 intermittent offset press with an automation package including pre‐register, semi‐automated plate loading and ejection and electronic registration. Each print unit is controlled by its own independent touch screen.

Even letterpress is not entirely dead. First‐time exhibitor Caisheng showed its latest CS‐JQ350G‐6C letterpress machine, which has two working modes, intermittent and full rotary.

Miyakoshi is an established supplier of intermittent offset press technology, and at this show demonstrated an upgraded MLP press incorporating the company’s Yaless AI intelligent press management system, allowing automated makeready and job data storage and recall.

DIGITAL STANDS ALONE

Stand‐alone digital presses with near‐ or offline finishing continue to be the most popular format for digital printing and converting of labels. Labelexpo Europe 2023 demonstrated that toner technology at the high end is now competing with flexo in terms of speed and productivity, while the core inkjet printhead providers are enabling a huge spread of new entrants to the four‐ to seven‐color inkjet market.

HP Indigo launched its V12 high‐speed digital press to the European market following its debut in Chicago last year. The V12 prints at 120m/min in six colors ‐ 60m/ min in up to 12 colors ‐ using HP Indigo’s new LEPx technology platform, which uses a rotary rather than intermittent feed blanket. HP Indigo was presenting the press as a replacement for multiple legacy flexo presses in terms of productivity, with significant reductions in makeready waste and manpower requirements.

As well as the global launch of the 200k (see below), the company also showed the established HP Indigo 6k workhorse in a web‐to‐print ecosystem including e‐printing software and digital shopfront and fully digital finishing ‐ digital embellishment and laser die‐cutting – on an ABG Digicon converter.

HP Indigo also continued to develop its automation and Cloud‐based connectivity platforms, including the launch of a Cloud‐enabled Spot Master package enabling converters to reach spot colors in minutes and keep them consistent during the run – including between presses at remote locations.

Xeikon made a string of announcements headed up by the launch of a new high‐volume toner press, the Xeikon LX3000 ‘Lion’.

Built for a web width of 330mm and with 1200dpi resolution, the LX3000 is a 5‐color dry toner press printing at 42 m/ min – a 40 percent speed increase from Xeikon’s current 30m/min capability. The press incorporates Xeikon’s Cruise Control system, which utilizes AI‐driven vision technology to continuously monitor and automatically adjust print production settings as well as providing quantitative production data for later analysis.

The Lion press was printing with Xeikon’s new Eco toners, formulated with over 60 percent high‐grade recycled PET. Free from fluorine, Bisphenol A (BPA), TPO and mineral oils, as well as being fully vegan, Eco toners comply with international restrictions around food safety.

On the inkjet side of its business, Xeikon introduced PantherCure LED‐UV inks with no price premium over conventional inks. Combined with Xeikon’s new Dionysus screening and bespoke waveforms, ink consumption is reduced by up to 30 percent and up to 88.7 percent of the Pantone book can be simulated with four colors at DeltaE 2. The Panthercure LED‐UV inks are available for the entry‐level Label Discovery Panther and Xeikon PX2200 and PX3300 presses.

Gallus demonstrated the recently launched GallusOne standalone digital press, built on the Labelmaster flexo press platform, and announced a new configuration that includes integrated semi‐rotary die‐cutting, flexo unit and inspection.

Although Gallus did not have a conventional press on its stand, it did highlight the newly available Digital Print Unit (DPU) which allows the ECS 340 (‘granite’) press to be field‐upgraded to a LabelFire 340 hybrid. Both presses share a common platform.

Durst unveiled its Hawk Eye real‐time nozzle compensation technology, enabled by an AI‐driven inline vision system. Hawk Eye automatically detects the exact position of a defective nozzle and the color. Neighboring nozzles then print larger drops to compensate at full production speed. There is no set‐up required and no need to print a special test pattern.

Durst also announced the availability of LED‐UV Tau RSC inks, available in CMYK with optional orange, violet, green and white, along with new Tau RSC UV Inks formulated without TPO photoinitiators. Durst sold a Tau RSC 340 E LED‐UV press at the show to PrintLounge in New Zealand.

The company demonstrated a Tau 510 RSCi press on the stand equipped with double white stations, allowing high opacity white ink printing at 80m/min.

Dantex showed the results of a partnership with Ricoh which boosts the resolution of its Pico UV inkjet digital press to 2400dpi. The jointly developed DRS (Digital Resolution System) utilizes Ricoh’s latest printhead technology encased in a stainless steel housing.

Dantex also unveiled a partnership with Actega Metal Print which sees the integration of its Ecoleaf digital metallization technology into the Pico press platform. Dantex was producing multi‐color metallic labels using the Color‐Logic system after having become a certified partner last year.

Further developments included the addition of Violet to the Picojet print engine, the inclusion of the Aegis inspection camera to monitor the press through Dantex’s proprietary Knight Guard system, along with a new semi‐rotary die‐cutting module.

Konica Minolta launched in Europe its AccurioLabel 400 toner‐based digital press, an addition to the hugely successful AccurioLabel 230. The AL400 prints at up to 39.9m/min and is fitted with automated color and density control and a white toner station along with a re‐registration scanner.

The AL230 was also present, configured with GM’s DC330Mini finisher. The setup included an integrated inkjet unit from Industrial Inkjet (IIJ) demonstrating inline security printing with reactive UV inks.

The company was also promoting its AccurioPro software suite which now includes Flux Label impose and Dashboard, promoting automation of job set‐up and VDP implementation and feedback of real‐time machine status.

Also shown was the PKG‐1300 inkjet press designed for short‐run digital box printing.

Screen announced the development of an inline inkjet primer station for its flagship Truepress LABEL 350UV SAI, which was launched at the show to address the issue of poor ink adhesion on some substrates.

The Truepress LABEL 350UV SAI A prints at 60m/min CMYK+WOB with chill roller for handling unsupported materials. A web reverse option allows the press to be configured as part of a hybrid press line. Screen also announced a new EuPIA complaint ink set.

India’s Monotech unveiled its Jetsci 2.0 dSpark digital label embellishment line with digital varnish and cold foiling capabilities alongside the company’s flagship KolorSmart+ digital UV inkjet label press. The KolorSmart+ press comes equipped with a pre‐inkjet flexo‐station for priming, coating, or single‐color printing, followed by a 6‐color print engine (W+CMYK+O). Print speed is 50m/min.

Epson showed its L‐4733AW flatbed water‐based inkjet press for the first time at a European trade show using Epson’s newly improved AQ4 ink set. Also shown was the SurePress L‐6534VW printing CMYK+W and in‐line digital varnish in-line with a GM DC330 Mini compact label finisher. Making its show debut was Epson’s new series of Cloud‐enabled ColorWorks label printers. This follows a partnership announcement between Epson and Loftware, the world’s largest cloud‐based enterprise labeling and artwork management provider.

Turkish manufacturer Jetron made its show debut with the D2Roll LB3350 LED‐UV inkjet press, running at 50m/min at a print resolution of 600 x 1200dpi and up to seven colors (CMYK+WOG). Maximum print width is 350mm. Jetron sees a gap in the market in terms of pricing between far eastern manufactured presses and ‘high‐end’ digital platforms. The company has developed its own workflow software.

DIGITAL FLEX PACK

Digital printing of flexible packaging was pioneered by HP Indigo with its highly successful 20000 press, now with 340 active installations. Not only did HP Indigo make this Labelexpo the occasion for the world premiere of the 200K – successor to the 20000/25k – but other manufacturers entered the digital flexible packaging arena, mainly emphasizing the opportunities presented by the shift towards paper‐based flexible packaging from film.

The HP Indigo 200K digital press offers 30 percent higher speed, and, says the company, 45 percent more productivity than the HP Indigo 25K digital press. The 200k was shown as part of a wider flexible packaging ecosystem, the Digital Pouch Factory, which included both lamination and pouch making machines provided by Karlville.

Xeikon launched its Titon dry toner system along with the TX‐500 press developed specifically for this application. The Titon technology involves encasing dry toners in a UV‐cured polyester shell which gives them a high degree of durability and heat resistance to temperatures up to 220‐260degC ‐ critical to withstand heat sealing processes.

Xeikon promoted the TX‐500/Titon combination for paper‐based pouches. The Titon toners are food‐safe and resistant to chemical and mechanical abrasion, meaning they do not need to be over‐varnished or laminated to protect the print.

Screen was also focusing on paper‐based flexible packaging for the introduction of its Truepress PAC 520P inkjet press. The press uses water‐based pigment inks that comply with appropriate food‐safety regulations. The press is designed to print on uncoated paper from 45‐250gsm at speeds of 80m/ min on a 520mm web width. It is supplied with a full‐color VDP capability. At its press conference Screen showed examples from Japan of digitally printed barrier paper packaging for multiple variants of a chocolate brand.

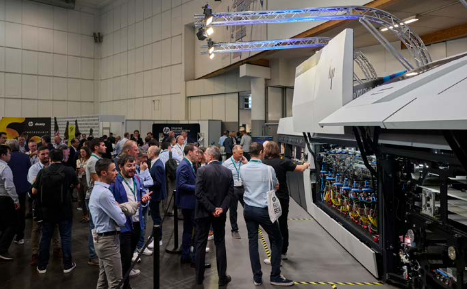

HYBRID IMPACT

‘Hybrid’ is becoming increasingly difficult to define, as digital presses start to incorporate flexo stations and flexo presses are fitted with digital processing modules, both print and embellishment. There is also some dispute about whether we should use the term ‘hybrid’ at all to describe flexo‐inkjet combination machines, with Bobst, for example, favoring ‘All‐in‐One’.

What we can certainly say is that Labelexpo Europe 2023 saw deepening relationships between flexo and digital press manufacturers to jointly develop inline integrated flexo‐inkjet presses.

Durst and Omet signaled a strengthening of their strategic partnership, with a commitment to jointly develop and manufacture the next generation of hybrid presses ‐ and for Durst to fully integrate sales and support of the hybrid presses throughout its global sales and service network. Omet demonstrated the current version of the XJet Omet‐Durst hybrid press on its stand.

Screen and Nilpeter introduced the latest generation of their jointly developed press (Nilpeter no longer uses the term ‘hybrid’), combining Screen’s new Truepress Label 350UV SAI technology with Nilpeter’s FA‐Line flexo platform. The Truepress Label 350UV SAI S unit offers up to seven colors, enabling expanded gamut along with high‐performance white printing. The FA‐4 UV flexo stations are sleeve‐based with closed chamber ink trays and can use any combination of LED‐UV or mercury UV curing. The press incorporates a quick‐change semi‐rotative die station.

With its established partnerships with Konica Minolta and Domino and its self-developed HD Series press, Mark Andy now offers six hybrid configurations that match flexo with inkjet or toner depending on the price point and application. The DPro Max takes full advantage of Konica Minolta’s new Accurio 400 engine to offer higher speeds and a white toner along with CMYK. Mark Andy’s new Pro Series flexo press is now field‐upgradable to this hybrid combination.

A particular point of hybrid interest on the Mark Andy stand was the addition of a Kurz Distorun metallization module on an HD Series press, allowing registered placement of foils and holograms. ‘This kind of embellishment is the future,’ says Phil Baldwin. ‘The quality is the same as using tooling and shows how flexo and digital complement each other – that’s the way the market is shifting towards hybrid fusions.’

Bobst announced a new ‘All‐in‐One’ press, the Digital Expert 340, built on the same platform as the Digital Master press which the company showed on its stand. The Digital Expert press will operate at 65m/min with the ability to upgrade to 100m/min and the option to incorporate a flexo unit.

Bobst revealed a strategic partnership with Asteria Group which involves Asteria’s investment in multiple Digital Master All‐in‐One production platforms throughout Europe.

Bobst also announced that Visutech has been appointed distributor for the Nordic countries representing the company’s complete narrow‐mid‐web product portfolio including flexo, digital and All‐in‐One machines.

Domino launched its N610i‐R digital retrofit module targeted at OEMs and converters looking to add digital printing into existing flexographic presses. The N610i‐R digital retrofit module is available in four or five colors (CMYK+W), with a double white option (WW+CMYK). The five‐color version allows for printing in high opacity digital white (72 percent) – often used as a replacement for silk‐screen printing – at 50m/min (164ft/min). Both color versions are available with Domino‐manufactured UV90 and UV95 ink sets. The UV95 ink set is suitable for non‐direct contact food packaging applications and is produced in line with Nestlé’s guidance on food packaging, EuPIA guidelines, and the Swiss Ordinance for Food Packaging Inks.

Amica Systems made a major move into the LED‐UV inkjet sector with the launch of two presses at Labelexpo – the LPS330 and the narrower web (up to 108mm) 6‐color Scorpio press. The LPS330 prints at 720x1200dpi configured with White, CMYK and digital varnish. The Scorpio prints in six colors, CMYK+OG. Also on show was the new Gemini 330 4‐color UV inkjet press fitted with automatic purge, wipe and cap functionality with print resolution of 600x1200dpi.

Chinese suppliers made a sizeable impact with hybrid press launches. First‐time Labelexpo Europe exhibitor Flora has diversified from its wide format technology base to launch its first narrow web inline press, the J‐450 Pro hybrid. The Flora J‐450 prints in up to six colors at up to 60m/min with a maximum print resolution of 1200 x 600dpi. It was demonstrated integrated with pre‐coating, cold stamping and flexo printing modules.

HanGlobal unveiled its LabStar330S Hybrid, which combines 7‐color digital printing with flexo, cold foil stamping, lamination and die‐cutting at 50m/min.

Upgrading from five to seven colors allows the LabStar330S engine to cover over 90 percent of Pantone colors. Optionally to adding OVG, along with White, inkjet varnish can also be selected for tactile effects and digital spot varnish.

Pulisi launched its Aobead multi‐functional digital press. The press demonstrated at Labelexpo, seen for the first time in Europe, was specially configured with multiple hybrid modules including front flexo primer, 7‐color (CMYK+white/orange/varnish) digital engine, cold foil stamping and inspection. The press uses Epson printheads for a resolution of 600 x 1200dpi in CMYK+W.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.