TPH Orient group establishes itself in labels and packaging

TPH Orient Group has expanded its portfolio to include fl exo and digital presses for the growing demands of the labels and packaging industry.

Labels & Labeling sat down with Rishab Kohli, managing director of the TPH Orient group, at the company’s 20-acre facility in Faridabad, Delhi NCR.

Founded in 1946 as a newspaper printing machine supplier, India-based The Printers House (TPH), better known by its brand name Orient, has evolved significantly over the years.

The company was originally founded by Rishab Kohli’s grandfather, KD Kohli, as a newspaper printing press provider, and over time, the elder Kohli began importing the latest printing equipment, providing qualified engineers for installation and training the crew for operations and maintenance. KD Kohli then began manufacturing small offset presses and Rishab Kohli emphasizes that in doing so, his grandfather became the first person in India to produce a letterpresses domestically.

Later, Rishab Kohli’s father took over the company and led it into manufacturing web offset printing machines for commercial print applications.

When Rishab Kohli took over the business in 2020 due to the unfortunate illness and subsequent death of his father, it was already thriving. Before stepping into his current role, he had worked as an investment banker in New York.

Today, TPH Orient has become a diversified group of companies, operating in six different industries including printing and packaging, defense and aerospace, chemicals, inverters and batteries, with solar energy being its largest vertical.

This presented a clear gap in the Indian market in the in-line flexo market, which has very few flexo providers and relies heavily on imports

Rishab Kohli explains that while his father focused solely on web offset printing, Rishab Kohli, along with his board of directors, took the company in a new direction. One of Kohli’s key collaborators was a former CEO for a large multinational and an executive for Cargill Foods, who is now a director on the board. Together, they expanded the business tenfold, which gave the company free cashflow to enter new market segments. With this growth, Kohli and his team analyzed new opportunities, leading to a decision to enter the labels and packaging segment.

He highlights that the technology for producing labels and packaging is familiar territory for the company, thanks to its long-standing expertise in press manufacturing.

Bridging the gap

The company entered the labels and packaging market with two technologies – flexo and digital. Kohli claims that Orient is the only company in India to manufacture in-line flexo technology with sleeves. The X-Press Flex Series flexo press offers web widths ranging from 330mm to 1,500mm.

The company’s unique selling point is its faster, wider presses and sleeve technology.

‘This was significant because, after a certain width, cylinders are no longer viable, and even label printers are transitioning to wider formats such as 650mm and 670mm. This presented a clear gap in the Indian market in the in-line flexo market, which has very few (domestic) flexo providers and relies heavily on imports. We saw the potential in meeting this demand with high-quality service support, as the sector requires significant investment in service engineers and infrastructure,’ he explains.

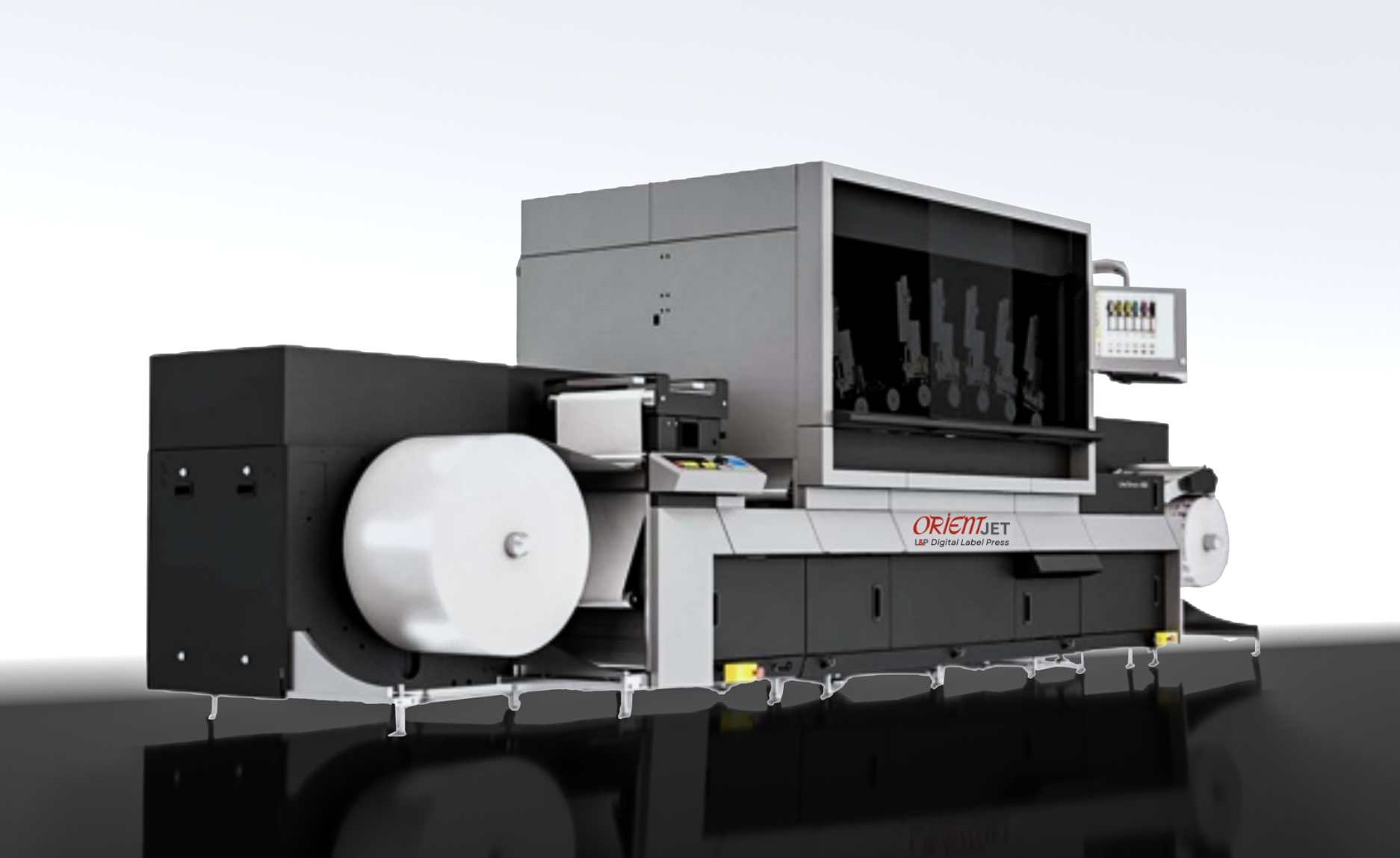

The second technology Orient developed for the label market was a digital inkjet machine, which took time to perfect. The digital inkjet machine is branded as the Orient Jet L&P Series and comes in both UV LED and water-based technologies.

‘Digital printing requires significant capital investment and expertise, and building this capacity takes time. Fortunately, India’s vast pool of talent, particularly from trading backgrounds, offers access to skilled professionals. We are optimistic about developing a company that can scale this technology effectively in the near future,’ Kohli says.

The digital presses web width ranges from 270mm, 330mm and can go as wide as 1,000mm and 2,000mm. The presses handle a wide range of substrates, including paper, film and labelstock. With a UV LED press, customers can print on several substrates, while water-based presses limit the substrate options but are becoming increasingly important due to food safety regulations.

‘Many in the industry are shifting from UV LED to water-based printing because UV LED is not food-safe. We are currently investing heavily in developing water-based, high-resolution (1,200 DPI) packaging machines that can print on film and labels, which could be a game-changer in the market,’ Kohli notes.

Orient has partnered with two UK-based firms to develop the software and hardware for the ink delivery system. Kohli underlines that the company was able to create India’s first fully homegrown ink delivery system.

The company manages both waveform matching and ink delivery system creation in-house, supported by a dedicated lab at its factory. This allows Orient to control both the production and servicing of its presses without relying on external vendors, providing a major advantage.

The company developed a digital press specifically for labels and packaging, aiming to compete with global leaders. Kohli’s strategy focuses on import substitution, aiming to offer domestic alternatives to major European and Chinese brands.

‘The specifications of our presses are comparable to other brands, with similar speeds and materials. The goal was to provide an Indian solution to the flexo and digital printing market, matching the quality of international competitors while maintaining self-sufficiency in service and production,’ he says.

Expanding global footprint

Orient has an extensive global network of 60 agents. This presence gives the company a significant advantage, as many of its agents have longstanding relationships in the printing industry. For example, his agent in Europe has previously represented several American and Chinese brands, giving it a solid foothold in the market. The company has sold machines to over 40 countries worldwide.

Kohli aims to expand India’s market share for its presses, as the majority of sales currently come from international markets.

He emphasized that his target market is global, with strong representation in Europe, where Orient has an office.

The goal was to provide an Indian solution to the flexo and digital printing market, matching the quality of international competitors while maintaining self-sufficiency in service and production

Each technology —flexo and digital—has its own dedicated team. Kohli notes that established agents have shown a keen interest in promoting both of his flexo and digital offerings.

He mentions that by this time next year, Orient also anticipates making significant strides in the US market with a new agent.

Although he already has an agent in the US, this new partnership would further strengthen the company’s presence in the region.

Fostering innovation

Kohli explained that his initial passion within the business came from digital printing, which was the fi rst area he delved into. Growing up, he was surrounded by industry experts owing to his father’s extensive network in the industry.

He recalls how these industry connections shaped his understanding, as he often socialized with these professionals, learning firsthand about the nuances of digital printing and the intricacies of the trade. His deep-rooted exposure allowed him to grasp essential concepts in printing early on.

He described his management style as hands-off when it comes to the day-to-day operations of the individual teams. Revenue targets are set by Kohli, but the team is responsible for managing its own sales and marketing strategies. Meanwhile, his focus is on exploring innovative aspects of the business and keeping up with new trends.

At the upcoming Labelexpo India 2024 and Labelexpo Europe 2025, Orient will showcase Orient X-Press flex 450mm 8-10-color dual servo flexo press, which he described as the most advanced machine ever made by an Indian manufacturer. Also running live will be the Orient Jet L&P series 7-color 330mm digital label press.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.