Linerless labels to stick around

While linerless label technology has been available for many years, and has a growing presence in the food sector, its impact has mainly been felt in the logistics market for applications such as case and pallet coding.

The benefits of linerless labels are well-known: elimination of release liner waste and, because more labels can be wound onto a reel, greater efficiency at the printing and application stages. ‘Linerless eliminates waste and reduces costs associated with label production,’ notes Benoît Pollacchi, global strategic marketing manager for tape and label at adhesive supplier Bostik.

Growing interest

Tim Broderick, segment leader for direct thermal label products at Appvion, agrees there is a strong sustainability story to sell to retailers and brand owners. ‘There has been a lot of talk around linerless for a few years, and asking if it is really on the horizon, does it provide the sustainability benefits promised and are there significant potential cost reductions? For all these reasons, people are now looking at linerless and the required equipment.’ Appvion has watched keenly as linerless has developed over the years. ‘We don’t see half of our volumes moving to linerless but it is definitely a growing area with more and more interest in it.’

Jeremy Woodcock, a print and packaging consultant who works with Ravenwood Packaging, describes linerless as, ‘a big story’ and a technology which has been around for over a decade. Ravenwood Packaging has around 1,000 applicators working in the market around the world, from Russia and Australia to Europe and North America, putting through around 30 million linerless labels a week. ‘With the exception of a few years in the late 2000s, the company has seen double digit year-on-year growth, and there’s no sign of it slowing down just yet.’

Craig Bevan, linerless sales director at Coveris, reports similar levels of growth, and says, ‘the market for linerless is booming’. The company’s recently released Compac Linerless multilayer (multipage) product, for example, gives retailers a viable way of meeting the challenges they face in the Food Information Regulations 2014.

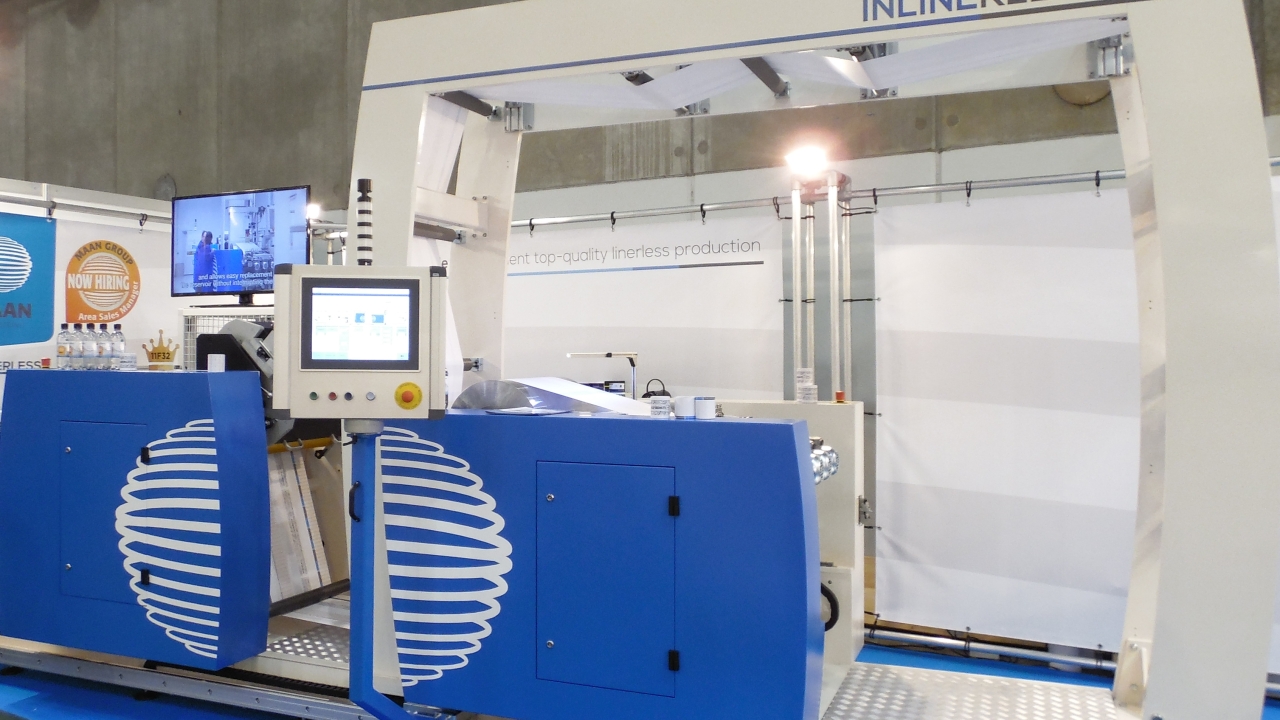

Roelof Klein, commercial manager at Maan Group, believes that linerless penetration stands at 20 percent globally, which is about the same as it was two years ago. ‘However, there is much more equipment available now which helps generate awareness amongst the industry and sell more machines.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.