Labelexpo India 2024 technology preview

With its largest edition yet, Labelexpo India is all set to welcome attendees from Nov 14 - 17, 2024, at India Expo Centre & Mart, Greater Noida, Delhi NCR.

The eagerly awaited four-day show will have more than 250 industry-leading exhibitors. The show will welcome many first-time exhibitors, who are all gearing up to make a significant impact. Other highlights include the Label Manufacturers Association of India (LMAI) awards at the end of day two, an evening to celebrate the outstanding achievements of companies and printers in the label industry.

This year, visitors will see the latest developments in print production technologies from leading manufacturers and suppliers. Below is a short technology preview from some of the exhibitors at Labelexpo India 2024.

Acme Rolltech, Addon Filmtech, APL, Arrow Digital, Avery Dennison, Bobst, Cosmo Films, Chiripal Poly Films, Domino, Durst, Epson, Flexo Image Graphics, Flint Group, GEW, H.B. Fuller, Henkel, HP, Intergraphics, Konica Minolta, Miraclon, Monotech Systems, Multitec, Newgen Printronics, Nippon Color, Onyx, Rotometal, Saiden Chemical, Shriram Veritech, Skanem, TechNova Imaging Systems, Texyear, Tsukatani, UV Graphic Technologies, Vetaphone, Vinsak, Webtech International Machineries, Weldon Celloplast, Wink, Xsys

Booth H21

Acme Rolltech promotes its new advanced channel engraving (ACE) technology that offers channel engraving and hexagon engraving cell structure.

The hexagon cell technology is being used by 98 percent of the flexo industry to this day but with the new age flexo presses and new advancement in inks and plate technology for printing at high speeds some applications and certain inks requires channel structure, according to the company.

The ACE technology combines the depth of channel engraving with high-quality halftone printing such as hexagonal engraving. Samples of the technology are showcased. Also on display are samples of Acme Tactile 2.0 anilox (ATAC 2.0) for screen type raised effect launched during Labelexpo Europe 2023.

Acme also shows samples of ECG printing done on its aniloxes and experts on booth are available for discussion on ECG with customers. Seeing increasing demand for label embellishment, the company launches Acme Glitter Anilox (AGLIT) customizable anilox for glitter ink/glitter applications. Acme Texture Gloss Anilox (ATXR G) is designed for special texture varnish applications such as texture, sand effect, rough effect and satin effect.

Acme Glitter Anilox Matt (ATXR M) can be used with AGLIT G and AGLIT M anilox to create a texture effects using regular matt and gloss varnish.

The company also launches its next generation Acme High Density White 2.0 which can now be used for high opacity white ink printing for unsupported labels such as IML, shrink sleeves , wraparound labels, ice cream labels and for small text matter.

Another new launch is its next generation engraving technology for conventional hexagon engraving, Acme Super Cell (ASC).

Booth M5

Addon FilmTech promotes its range of shrink films. Products featured at the company’s stand include PET shrink labels that offer full body coverage with 360-degree design. The shrink film’s tamper-evident seal ensures protection from adulteration and adhesive-free application on the bottles and containers enabling recycling of the rigid bottles and containers.

The company shows its range of PET, CPET, PETG, RPET and co-polyester shrink sleeve films which can be recyclable and contain post-consumer recycled (PCR) waste content, a replacement for PVC shrink film. Applications of the films include labeling food, beverage, pharmaceutical, cosmetic, homecare and dairy products.

It also showcases its HSP grade film, suitable for the beverage industry or similar sectors where labels are applied at the final stage of the packaging line. WF is Addon’s specialized grade of PET shrink film, compatible with all types of materials such as HDPE, PP, PET, glass, and metal. It is suitable for use in all types of shrink tunnels, including steam, hot-air and electric. CSP is the company’s crystallizer-friendly grade film which when printed with washable inks can be removed during the washing process of PET bottle recycling. RSF grade film contains a minimum of 30 percent PCR content.

Booth D2

APL Machinery unveils a range of high-performance machines designed to meet the evolving needs of the label printing industry, offering enhanced productivity, print quality and sustainability.

The booth showcases APL’s roll-to-roll screen printing machine, designed to cater to various roll-to-roll printing applications. Label producers can bring flexibility to their production process with this machine. It can print on pre-printed rolls, providing options for spot coating and reprints. Available in single and double-color models, the machine is equipped with a drying system—available in both UV and IR—ensuring fast and efficient drying, suitable for large-scale operations where speed is critical.

The machine can handle complex printing jobs with enhanced accuracy and print on various substrates, including paper, plastic and foil—enabling label manufacturers to diversify their product offerings.

Another highlight at APL’s booth is the Quantum Jet 47 digital printing machine. Designed specifically for the label and packaging industry, this machine is tailored for businesses that require high-quality digital printing with quick turnaround times. The Quantum Jet 47 can produce vibrant, detailed prints in less time than other traditional machines while maintaining quality, according to the company.

The machine has an intuitive interface and advanced printing capabilities. It can handle large batches or small and customized orders.

APL also showcases the tabletop digital label printing machine. The printer offers the flexibility to print high-quality labels on demand, with minimal setup time and reduced wastage. Despite its compact size, the machine can handle a wide variety of label materials and sizes, enabling businesses to meet diverse customer needs, while being affordable.

APL Machinery also introduces its LED UV systems for retrofit in label machines. These systems are designed to be easily integrated into existing label machines, offering a sustainable, energy-efficient solution for curing and drying processes. LED UV curing technology is not only faster but also more environmentally friendly, consuming significantly less energy than traditional curing methods.

The LED UV system is suitable for label printing, where quick drying and high print quality are paramount. LED UV curing technology extends the lifespan of printing equipment by producing less heat, reducing wear and tear on the machine components.

Visitors can schedule a session with APL’s expert team to provide demonstrations, answer questions and help find the right printing solution for their business needs.

Booth B30

Arrow Digital introduces ArrowJet UV – a single-pass UV LED inkjet printer. With a maximum print speed of up to 400 feet per minute (122 meters a min) and a resolution of up to 600 DPI, it delivers high-quality output very fast. Its maximum printing width of 17 inches and ability to work with media widths of up to 18 inches.

It can be customized in 4-, 5-, 6- and 7-color configurations, depending on client need. Additionally, it features in-line flexo stations for priming and varnishing, along with an in-line rotary slitter. ArrowJet UV’s retrofit options make it an easy addition to any workflow.

The printer can print on a variety of media, including papers, films, foils and synthetic materials. Its chill rollers support printing on heat-sensitive media. With UV LED curing technology, the printer ensures energy efficiency and fast drying. An optional mercury curing feature is also available.

Arrow Digital’s CEO, Sam Patel, said: ‘At Arrow Digital, our goal has always been to push the envelope and bring cutting-edge technologies to our customers. With the ArrowJet UV, we believe we've hit a new milestone in digital label printing. We have used the best electronics and ink delivery systems, along with the best PLC-based automation unlike most of our competitors who use cheaper components, we have focused on stability and reliability. It offers a perfect blend of high-quality output and speed, meeting the growing need for short-run, customizable jobs. This is something the industry has been waiting for and we are thrilled to deliver it.’

The ArrowJet UV can be used for a wide range of applications, including labels, flexible packaging, security printing, batch coding and digital embellishments. It caters to the needs of food and beverage, pharmaceuticals and personal care industry.

Booth C15

Avery Dennison brings new innovations to enhance sustainability, optimize the supply chain, and foster stronger connections between consumers and brands.

‘We are eagerly anticipating the opportunity to reconnect with our South Asian partners and showcase how our cutting-edge technologies can elevate their brands,’ said Saurabh Agarwal, vice president and general manager, materials group, South Asia. ‘Our focus this year is on presenting a suite of advanced solutions that not only highlights our next generation label technology, but also how connected packaging solutions build consumer interaction and provide end-to-end transparency.’

The company shows a range of products including the sustainable ADvantage portfolio, which features labels designed to minimize material use and promote recycling and reuse. Additionally, the specialty portfolio highlights labels that enhance a brand’s premium appearance and include anti-counterfeiting solutions to meet growing regulatory and safety requirements. The company showcases innovations for emerging markets such as energy storage, EV batteries, solar, and mobile, offering high-performance bonding and labeling products. Avery Dennison's extensive RFID portfolio will further bridge the gap between the physical and digital realms to unlock end-to-end traceability and enhance consumer engagement. Visitors will also discover unique services, including Avery Dennison’s customer portal, compliance, and its recycling program.

‘At Avery Dennison, innovation is at the heart of everything we do. Our participation in Labelexpo India 2024 reflects our dedication to driving progress within the industry and supporting our customers' efforts,’ added Manoj K.M., director, sales and technical services, materials group, South Asia. ‘We believe that by collaborating with our partners and sharing insights on the latest trends, we can collectively shape the future of labeling and packaging.’

Visitors and customers are encouraged to participate in the knowledge sessions that Avery Dennison hosts throughout the event to gain deeper insight into the industry landscape and the work Avery Dennison is doing to help to solve key industry challenges.

Booth G32

Bobst exhibits its narrow-mid web flexo products for labels and flexible packaging focusing on connectivity, digitalization, automation and sustainability.

The stand features Bobst flexo products, machines with high levels of automation and advanced UV LED curing technology, delivering print quality while reducing energy consumption and environmental impact.

‘We’re thrilled to demonstrate to converters across the South Asian market how label solutions by Bobst are revolutionizing label printing,’ said Patrick Graber, marketing director for narrow, mid-web printing and converting product line at Bobst.

‘Label converters worldwide are facing increasing demands for speed, efficiency and sustainability. Bobst shines in this area as one of the world’s most established press technology and service providers. Our tailor-made and upgradable solutions offer unparalleled automation capabilities, and its integration with Bobst Connect provides a complete solution for maximizing productivity and quality.’

Bobst also highlights oneECG (its extended color gamut technology), developed to offer seamless color management and savings in electricity, waste, set up time and ink usage, with its high-performance die-cutting machinery and flexo automation features.

In addition, visitors can explore Bobst Connect, the company's cloud-based platform that offers users a complete overview of their production process, from the PDF to the finished product.

This tool provides real-time data and insights, enabling smarter decision-making and improved operational efficiency through the narrow web printing workflow.

Bobst experts are available to discuss how the company's comprehensive flexo technology portfolio can handle a variety of applications, from simple pressure-sensitive labels to complex applications, such as multi-layer labels.

‘We are delighted to have Reifenhäuser India, the Bobst authorized sales agent for narrow mid-web flexo solutions in India, join us at the stand. It’s a great opportunity for visitors to connect and arrange a one-to-one meeting with our team in advance,’ said Peter Woods, zone business director for labels in the APAC region at Bobst.

Cosmo Films will showcase its comprehensive range of label products, emphasizing Cosmo Synthetic Paper. The company will also present its specialized portfolio including label films, PET-G, in-mold label films and wraparound films.

Kulbhushan Malik, global business head, Cosmo Films said: ‘The labeling industry continues to evolve with changing market demands, and innovation in label solutions has become crucial for brand differentiation. At Cosmo Films, we’re particularly excited about our Cosmo Synthetic Paper, which has been gaining significant traction in the labelling segment. Labelexpo India provides us the perfect platform to showcase these innovative label solutions and connect with customers looking for high-performance, sustainable labelling materials.’

Booth K30

Chiripal Poly Films showcases its wide range of BOPP-based products for self-adhesive labels, in-mold labels and wrap-around labels, along with Bopet-based products for release liners.

Booth A22

Domino showcases its exhaustive range of advanced technologies and offers live demonstrations of its latest technologies designed to streamline operations. The team is present for interaction with visitors.

Booth G8

Durst Group presents its Tau RSC E 7-color low-migration machine at the Newgen Printronics booth. The machine is designed specifically for applications requiring low-migration inks. It is suitable for sensitive applications, such as food and pharmaceutical labeling.

Visitors can attend live demos and feel samples to understand Durst technology and appreciate quality.

Alongside the Tau RSC E, Durst introduces the Hawk AI technology, which utilizes camera vision systems to automate print quality, resulting in significantly reduced waste and overall improved print quality. The Durst Hawk AI also corrects print mistakes, such as missing nozzles, in-line and in real time, without any setup or operator intervention.

Visitors explore Durst’s comprehensive portfolio, which includes the RSC E, RSC and RSCi, as well as hybrid machines like the KJet and XJet, developed in collaboration with Omet.

Thomas Macina, sales director at Durst Group for labels and flexible packaging, said: ‘We are excited to partner with Newgen Printronics to bring our latest label printing innovations to Labelexpo India. The Indian market is growing rapidly, and we see immense opportunities to support converters in modernizing their operations with our advanced digital and hybrid solutions. Our dedication to quality, productivity, and customer-centric solutions will be on full display at the event.’

Selvaraj Venkatesh, managing director of Newgen Printronics, added: ‘Our collaboration with Durst enables us to deliver best-in-class label printing solutions to our customers in India. At Labelexpo India, we’ll showcase how our joint expertise can help label converters scale their businesses with efficient, cost-effective, and high-quality printing solutions.’

Detailed information on inks, applications, software and service is available, offering a complete insight into Durst’s range of products for enhancing production capabilities. Visitors can engage with industry experts from Durst and Newgen Printronics to discuss tailored technologies for their specific production needs.

Booth K14

Epson debuts its new UV inkjet digital label press, SurePress L-6534VW UV. The company will have a live demonstration of the machine at its booth.

The company also showcases Epson Colorworks on-demand label printers to enhance efficiency and quality in label and package printing.

SurePress L-6534VW UV is designed to meet the demands of high-quality label production, offering enhanced print quality and flexibility for a wide range of applications. The digital inkjet label press produces consistent color and enhanced finishing at speeds of up to 50m per min and is equipped with digital varnish. It supports various substrates and is equipped with advanced color management tools to ensure consistent color accuracy. Visitors to the Epson booth can also check out the print samples of SurePress L-4733AW, a water-based resin ink digital label printer that can deliver accurate spot colors and gradients.

Epson’s SurePress printers offer high-quality prints, expanded color gamut, consistency and flexibility for label converters. All Epson SurePress models are pantone-certified.

Another highlight at the booth is Epson’s Colorworks CW-C6500A on-demand, high-quality color label printer that helps maximize efficiency and reduce obsolete inventory costs. The printer is designed for high-speed production environments and helps lower printing costs without compromising quality.

Epson will also showcase its Labelworks printers. The compact, easy-to-use label printers, the LW-300 and the LW-1000 are designed to deliver labels for various applications. Businesses looking to enhance their branding and operational efficiency can use these printers. The LW-300 is an intuitive label printer delivering quality while the LW-1000 is ideal for high-volume label printing needs.

'Epson has always focused on delivering compact, efficient and energy-saving products that deliver amazing output quality. We are taking label printing to a whole new level now. We are excited to introduce our industry-defining UV inkjet digital label press, the SurePress L-6534VW UV for the first time in India, along with our Coloworks and Labelworks label printers,' said Satyajeet Satpathy, director of sales and marketing, Epson India. 'With our innovative lineup, including versatile, high-quality label printers, we aim to empower businesses with enhanced branding capabilities and operational efficiency. At this event, we look forward to connecting with customers seeking diverse labeling solutions, from creative design to high-volume printing capabilities, all while maximizing productivity and minimizing waste.'

Booth C13

Flexo Image Graphics (FIG) promotes the non-stop roll-changing systems from China-based, Dym Machinery. Dym’s key products consist of HAU non-stop unwinding, WBU/WBC non-stop cold stamping systems, NAC waste removal systems and SAC automatic turret rewinder.

The FIG booth also demonstrates the Rhyguan die-cutting and Luster inspection system. Booth also features machines from Mark Andy and Rotoflex.

Talking about the show, Gourav Roy, director, FIG, shared: ‘Labelexpo India 2024 will be an exciting platform for us to do live running of key machines from Rhyguan and Luster. The live demonstrations of the Rhyguan die-cutting machine and Luster inspection system will allow FIG’s clients and visitors at the show to get hands-on or onsite experiences of the machines.’

Roy further mentioned that the FIG stand at Labelexpo India 2024 will feature many other technologies besides live machine demonstrations.

‘At our stand, there will be a designated print sample gallery where label prints produced on Mark Andy Pro Series presses will be displayed,’ added Roy. FIG’s stand at the show will display machines of various brands, print samples and much more.

Booth L5

Flint Group showcases EkoCure Dual Cure inks, formulated to cure under both traditional UV Hg and UV LED lamps. This technology enables printers to use one ink on all presses while transitioning to UV LED curing, reducing their need for excess ink inventory.

Upal Roy, managing director of India, South Africa and Middle East at Flint Group, said: ‘With sustainability and efficiency becoming increasingly important, technologies like EkoCure provide converters with an invaluable asset. This range supports them in simplifying their ink inventory management while investing in UV LED curing stations, granting the flexibility to transition at their own pace without added complexity. As a result, converters can start benefiting from the lower energy consumption and waste associated with UV LED curing faster than ever. We can’t wait to demonstrate its benefits at Labelexpo India this year alongside Flexocure Ancora and our industry-leading support services.’

The booth also features Flexocure Ancora – UV flexo ink designed to meet the stringent demands of food packaging printing. This range delivers enhanced press performance and adhesion, making it suitable for self-adhesive labels, wrap-around labels, in-mold labels, unsupported films and sleeves.

Experts from the company also demonstrate Vivo Color Solutions, an end-to-end web-based color management process designed to ensure recipes are tailored to customers’ unique ink chemistries, substrate selections and anilox choices.

Attendees can also learn about FlintLink – Flint Group’s digital portal that provides customers with real-time access to the critical information such as order details, delivery notes, invoices, safety data sheets, certificates of analysis, the Flint Group webshop and other important documents and data points.

Sreenivas Goud, director for sales narrow web, India and exports at Flint Group, said: ‘Labelexpo India serves as a hub for innovation, showcasing the products and technologies shaping the future of the narrow web printing industry. Our team is looking forward to connecting with printers at this year’s event to present our revolutionary ink ranges that are driving efficiency and sustainability across the industry. We are eager to engage with visitors and encourage anyone interested in learning more to book a meeting with our team today.’

Booth H16

GEW highlights two new high-performance LED products—AeroLED2 as a successor to GEW’s air-cooled AeroLED UV curing system and LeoLED2 as a successor of water-cooled LeoLED system.

AeroLED2 maintains the key attributes of the earlier model: it is ArcLED compatible, meaning that it can easily be interchanged with GEW’s Arc lamp systems, and it maintains GEW’s unique centralized fan cooling architecture.

LeoLED2 introduces two power level options. The regular power option offers modest gains over the original LeoLED, while maintaining backward compatibility. The high-power option has increased UV irradiance and dose over its predecessor.

LeoLED2 also maintains the key attributes of the earlier model: it is ArcLED compatible, meaning that it can easily be interchanged with GEW’s Arc lamp systems, and the same level of temperature control and condensation protection. It is also fully backward compatible with LeoLED, featuring the exact same connections and external dimensions.

The stand also showcases GEW’s ArcLED technology.

Booth C15

H.B. Fuller shows Swift melt 1892 that provides high adhesion, die-cutting performance and delivers a balance of peel, tack and cohesion. This ensures productivity while securing bonding excellence. It offers high performance to a range of substrates for high-quality general-purpose paper and filmic labels.

Additionally, H.B. Fuller shows a comprehensive range of high-performance pressure-sensitive adhesives, including microsphere, water-based, solvent-based, hot melt, and UV acrylic PSAs for the production of tapes, labels and protective films.

Booth F12

Henkel highlights its extensive pressure-sensitive adhesives (PSA) portfolio, with a focus on sustainability and efficiency.

With a selection of adhesive technologies, including hotmelt rubber, UV curing, water-based, and solvent-based acrylics,

Henkel offers solutions for a variety of labeling applications ranging from shampoo bottles to pharmaceuticals, e-commerce packaging, tyres, automotive decals, and consumer durables.

A key is Henkel’s Aquence PSA range, a sustainable, water-based solution designed for versatile applications. Also featured is the Loctite Duro-Tak range, part of Henkel’s UV-curing lineup, engineered to address complex manufacturing needs with a wide range of performance attributes.

Additionally, the ECO and RE PSA portfolio is presented, emphasizing Henkel’s dedication to reducing CO2 emissions, minimizing waste, and supporting high-quality recycling in label production.

Henkel also launches Technomelt PS 8011, a high-performance hot-melt PSA crafted for labelstock applications. Technomelt 8011 delivers high tack, peel strength, and die-cutting compatibility for both flatbed and rotary die. Its formulation prevents face stock penetration and aging discoloration, ensuring compatibility with standard applicators, including nozzle and slot. This adhesive is suitable for medium to high-speed coating lines, with the added benefit of effective bonding at lower temperatures, down to 0 degrees Celsius, making it adaptable to various production environments.

Booth E20

HP Indigo Digital Print division has collaborated with Technova Imaging Systems for Labelexpo India 2024. At the show, HP will exhibit HP Indigo 6K digital press.

Moreover, HP promotes HP Indigo V12 high speed digital printing press for the converters to achieve high productivity PS label printing with a speed of 120 meters a minute.

The HP PrintOS software suite helps converters automate the entire production line and produce higher volumes thanks to its complete ecosystem across leading industry players.

The HP Indigo 200K will also be promoted for flexible packaging. 15 percent of HP Indigo’s label converters are using the HP Indigo 200K and 25K to diversify their business and tap into digitally printed flexible packaging, among the fastest-growing segments in print.

At the booth, visitors will also be able to see live demonstrations of the HP Indigo 6K digital press. Plus, adjoining stations such as PrintOS with spot master, value added services, to show how to reach spot colors within minutes and streamline the print process, or automated workflow solutions to demonstrate how intelligent automation can address key customer challenges such as labor shortages, waste reduction, mass customization, and on-demand production. The booth will also present other solutions such as XR Services, security and brand protection, sustainability with the CO2 calculator, and an extensive customer application showcase.

Booth J25, J22, J3

Intergraphics launches Pulisi DSmart330F UV inkjet digital label press. This press is designed for high-quality, flexible printing options, catering to medium and short-run jobs.

It can print on a wide variety of substrates, ranging from thin films (30 microns) to thicker materials (up to 300gsm).

The press uses multi-level ink droplet technology, ensuring fine printing details and smooth color gradients. It supports full-color output and spot-color simulations.

The DSmart330F supports variable data printing, allowing for easy customization of labels with barcodes, QR codes, serial numbers, and other personalized elements.

A key feature of the press is its integrated post-press inspection system. It helps detect and rectify printing errors like missing text, color variations and misaligned elements.

The machine can be configured with various optional modules, such as digital cold foil stamping, film lamination, die-cutting and in-line quality inspection.

Both K28

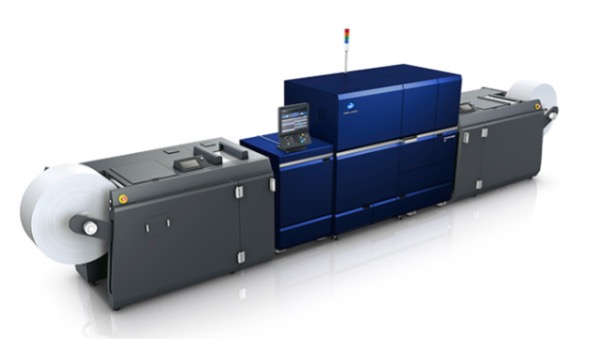

Konica Minolta showcases its AccurioLabel range. The AccurioLabel 230, third redesign offering accelerated speed of 23.4m a minute, reduced warm-up time, and an optional over-print kit for running preprinted media. It boasts improved winders and updated tension control for smooth and efficient roll material handling up to 600mm and can run a single job up to 1000 linear meter. AL230 prints labels on tack papers and tack films as well as standard labelstocks from the retail, logistics and healthcare sectors.

The AccurioLabel 400 brings CMYK with white toner capability, faster print speeds of up to 39.9 meters a minute, and can run a single job up to 3000 meters.

It is available in 4- and 5-color configurations, which allow flexibility and high print quality. It serves industries that require personalization, shorter delivery times, and on-demand runs for food, beverage, cosmetics and industrial labels.

Booth E26

Miraclon showcases the opportunities and benefits of modern flexo and how it enables converters to achieve their efficiency, sustainability and quality goals while maximizing returns.

The booth showcases real-life case studies of commercial success, highlighting new product innovations that build on the strength of core Flexcel NX technology and provide access to Miraclon technical and commercial experts.

‘Flexo is evolving from its “traditional” capabilities, practices and processes to a new era of modern flexo that is a standardized, sustainable manufacturing process,’ said Andy Yarrow, regional commercial director, Asia Pacific Region, Miraclon. ‘The lack of skills in the industry, combined with the pressures on printers to increase yields and implement sustainability improvements necessitates less “craft”, and more efficient, intervention-free printing that can cope with the full range of client demands. At Labelexpo India, our team will show visitors to our booth the best way to address these demands efficiently.’

The company shows real-life case studies of printers and trade shops that have met challenging brand client needs and achieved financial and sustainability goals after implementing Flexcel NX technology. Expert knowledge-based services are promoted Including consultancy, savings tools and calculators, and technical and applications support to enable printers to maximize their returns in the press room.

Yarrow concluded: ‘Any visitor to our booth during Labelexpo India is guaranteed to see how Flexcel NX Technology, together with our team’s knowledge and expertise, can optimize the flexo label and packaging print production process and help maximize returns. They should not miss the opportunity to let us show them why partnering with Miraclon is the first step in their journey to modern flexo success.

‘While we will not launch a physical product, we are introducing a methodology called Modern Flexo that utilizes latest technology to deliver a host of benefits for print packaging businesses. We will be showcasing the methodology and some case studies of printers from India, Asia and around the world who have adopted modern flexo.’

Booth G24

Monotech Systems debuts a series of Jetsci inkjet machines offering range of digital label printing and embellishment techniques to track and trace options.

Monotech showcases its latest advancements in digital label printing, designed to deliver high quality, speed and versatility. Visitors can see live demonstrations of the technologies.

Another highlight is its digital label embellishment press that offers foiling, embossing or custom textures to enable brands to differentiate themselves in a competitive landscape.

Tej Prakash Jain, managing director of Monotech Systems, added: ‘The trends at this year’s Labelexpo India are set to spotlight the transformative potential of digital labels and packaging. Visitors will have the opportunity to explore a diverse array of narrow format solutions, with print widths of 17in and 20in on display, showcasing the latest advancements in digital printing technology.

‘Labelexpo India 2024 will be an exciting showcase of how digital printing and embellishment solutions are revolutionizing the label and packaging industry. Industry professionals, converters and brand owners will find valuable insights and innovative solutions that can help them stay ahead in a competitive market, driving both efficiency and creativity in their production processes.’

The company’s advanced track and trace technology, under its brand Tracesci is also a focus. These systems are essential for ensuring brand integrity and consumer safety by providing comprehensive product identification and monitoring throughout the supply chain.

Monotech also displays Ricoh Pro C7500 11-color digital production press for printers looking for label production in sheetfed format.

'Our participation in Labelexpo India is an exciting opportunity for Monotech Systems to showcase our latest innovations and demonstrate how they can drive success for businesses in the label printing sector,’ said Gurvinder Singh, director – sales and marketing at Monotech Systems. 'We are dedicated to pushing the boundaries of what’s possible in printing technology and we invite everyone to visit our booth to explore how our solutions can transform their operations.'

Attendees can book their demo sessions in advance through the Jetsci website to secure a personalized experience.

Booth H32

Multitec demonstrates the double servo mid-web S2 9-color press, which features a 670mm web width and runs a 12-micron substrate at a speed of 200 meters a minute.

Multitec is positioning the new machine as a choice between digital printing and CI flexo or rotogravure technologies.

Designed with a heavy-duty frame, it operates free of vibrations, ensuring smooth and consistent performance. It also features advanced anti-bounce technology, which minimizes bounce-related issues, allowing for greater precision and print quality during high-speed runs.

This press is suitable for converters looking to break into the short-run flexible packaging market, offering versatility for applications such as pouches, shrink sleeves and in-mold labels (IML).

The S2 features intelligent, centralized digitized operation and features advanced systems, including LED and high-powered UV curing, an extended-path in-line solvent drying unit, pre-register, auto-register and automatic job settings. Additional capabilities, such as a movable turnbar and foiling options, allow converters to handle several jobs. Converters can create high-end products with soft-touch varnishes, foiling and other value-added finishes in flexible packaging.

The company shows a second S2 press, a 450mm-wide, 8-color double servo model printing shrink sleeves live. This press includes hybrid LED UV curing systems, die-cutting units, pre-register, auto-register, a movable turnbar, delam-relam units, a peel-and-seal kit and foiling stations.

Both presses in the S Series can handle substrates ranging from 10 to 450 microns, running at speeds of up to 200m/min, while delivering registration accuracy and minimal setup waste.

Multitec hosts live demonstrations and presentations on these advanced features at its expansive 355sqm booth.

Booth G8

Newgen Printronics exhibits Durst Industrial UV inkjet digital press for multiple applications such as labels, IMLs, shrink sleeves and lamitubes.

The company also promotes Omet flexo press with multi-technology, products from Polly Automatic – PRC, Packers automated die punching machine for IMLs, wet-strength paper labels, ice cream cones and Aluminum lids.

Also promoted on its booth are Berhalter die-cutting technology, DCM converting machines for flexible packaging and shrink sleeves, Heaford plate mounting system, Allen Pack flexible packaging converting machine provider, Lundberg all-in-one units and a central system for waste handling, Rotary Technologies – PRC tooling for narrow web flexo segment and Alphacure UV/IR lamps for flexo press and sheetfed presses.

Booth N37

Nippon Color launches the VD330 digital label die-cutter. Notably, it excels in unwinding, laminating, half cutting (up to four cutting heads), matrix removal, slitting, and rewinding/sheeting.

The machine offers automatic job changeover facilitated by AI technology. The CCD camera scans the mark and reads the job number, enabling seamless job transitions without any operator intervention. This feature enhances productivity, allowing digital label printers to offer a complete digital workflow to customers.

The VD330 provides up to four cutting heads. This design choice is aimed at boosting speed and productivity. The distance between the heads is calculated automatically and adjusted for each job, ensuring optimal performance without manual intervention. The machine offers both roll-to-roll and roll-to-sheet configurations.

Nippon has installed five VD330 digital label finishers in India. Customers include label converters utilizing digital printing technologies for short-run jobs, as well as converters using flexo printing who prefer the convenience of a digital finisher.

Booth A29

Onyx Equipments showcases AstroNova's entry-level tabletop color label printers under QuickLabel and wide-format, high-volume, direct-to-package printing machines under TrojanLabel.

The QuickLabel QL-E100 features standalone, all-color print capabilities that provide enhanced, professional results. It is easy to use, compact, portable and features a built-in touchscreen interface for seamless print management.

The QuickLabel QL-120Xe is an economical entry-level option for businesses considering in-house color label printing.

The TrojanLabel T2-Pro is a compact, floor-model A3+, fully featured digital inkjet label press. It prints at 1,600 x 1,600 DPI resolution, up to 30 ips (46m/min), and has a maximum print width of 12.75in (324 mm).

Another highlight at the booth is the TrojanLabel T2-C high-volume tabletop label press. As per the company, this tabletop label press can deliver precision over long runs.

The T2-C has been designed to bridge the gap between compact, inexpensive desktop label printers and expensive, large commercial label press to provide highly flexible and productive machinery for printing medium to large-run labels. Equipped with economical 2-liter ink tanks, the T2-C provides a combination of increased print accuracy and reduced price of ink, offering cost savings over the printer's life.

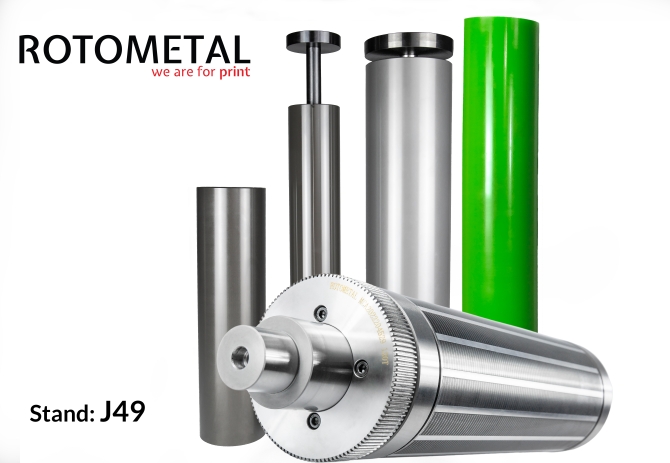

Booth J49

Rotometal showcases a suite of innovative products. The key highlight at the stand is its magnetic cylinder AluLite. The lightweight design significantly reduces cylinder weight without compromising performance. The AluLite cylinders, particularly those over 120T, can reduce weight by nearly 50 percent.

Another highlight is the print cylinder Antifriction. Utilizing a specialized anodizing process with a unique polymer matrix, this product achieves optimal surface smoothness while maintaining hardness.

Also on the stand is its rotoSleeves Eco product line, crafted from recycled and naturally derived materials, including 100 percent recycled PET.

In addition to these products, Rotometal presents a wide array of other rotary tooling systems including magnetic cylinders, print cylinders, print sleeves, sheeters, anvils, bases for sleeve anilox, embossing cylinders, air cylinders, cutting units, gears and cylinder storage solutions.

Japanese manufacturer of pressure-sensitive adhesives (PSA) Saiden Chemical showcases a range of new PSAs.

The company displaysboth water-based and solvent-based PSAs. Additionally, the manufacturer introduces its range of removable PSAs, which provide strong initial bonding yet allow for clean removal when needed.

Saiden Chemical’s team of experts is on hand to discuss how its products can be customized to meet specific requirements.

Booth H30

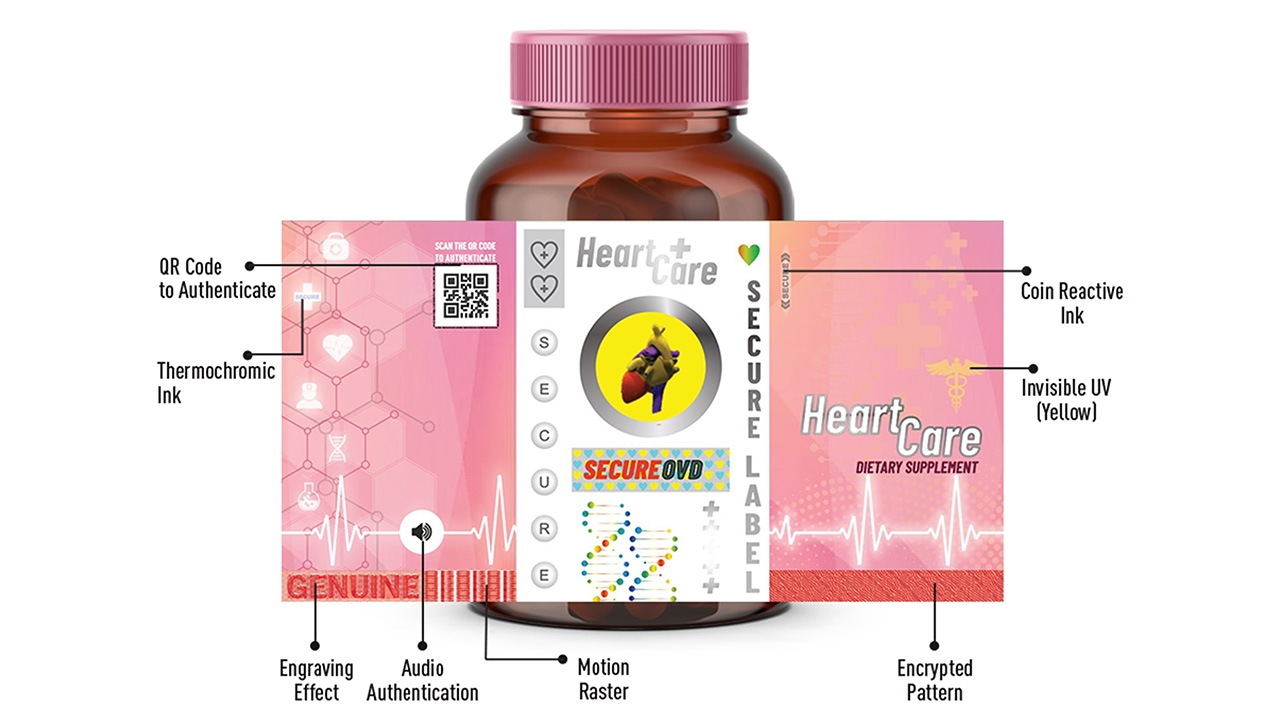

Shriram Veritech showcases innovative labeling and packaging products, including its intelligent label addressing issues such as counterfeiting, tampering, repackaging and digital authentication. Utilizing advanced registered printing and holography, this label integrates over 20 advanced features to ensure security.

Luv Shriram, managing director of Shriram Veritech, said: ‘We are thrilled to participate in this esteemed exhibition, showcasing our leadership in advanced labeling and packaging solutions. Our presence at Labelexpo India underscores our commitment to innovation and quality, as well as our dedication to supporting industries in addressing their all kind of labeling and packaging needs, while protecting their brands and enhancing product integrity. Effective brand protection is a collaborative effort, and our goal is to not only prevent counterfeiting but also foster partnerships that contribute to a safer, more reliable market environment.’

Shriram Veritech booth also features aluminum foils, shrink sleeves, product labels, holographic labels and in-mold labels, all customized to meet the unique needs of customers and protect packaging from tampering and counterfeiting.

Booth N45

Skanem introduces eco-friendly labels, focusing on sustainability and the use of recyclable materials that adhere to global environmental standards.

Visitors to the Skanem booth can expect to explore a wide array of labels, including self-adhesive labels, shrink sleeves and in-mold labels, as well as learn about various label applicator machines.

Skanem anticipates that sustainability is a key trend at the event, with brands increasingly seeking eco-friendly and innovative packaging solutions that also offer cost optimization and added value in customer interaction.

Booth D26, E20

TechNova Imaging Systems is present at two stands. At the first stand, the company partners with HP to showcase live demonstrations of the HP Indigo 6K digital press. Visitors can experience a digital supermarket, featuring real-life labeling and packaging applications, highlighting the capabilities of digital print technology.

At the second stand, TechNova presents an extensive range of flexographic technologies. Key highlights include AEP grade and BFTK grade solvent-wash flexo plates, and water-wash CleanFlat flexo plates from Asahi. Additionally, the newly launched DWF95DG and DWS73DY grade letterpress plates from Toray are featured. The stand also displays Toray’s GB grade waterless offset plates, a diverse range of UV flexo and special Pantone shades inks and varnishes from SakataINX and essential flexo chemicals, such as UV wash and anilox cleaning products.

Furthermore, TechNova exhibits a range of flexo CtP systems and advanced packaging software from Esko.

Amit Khurana, CEO, TechNova Imaging Systems, said: ‘At Labelexpo India 2024, visitors can expect to see groundbreaking advancements that are shaping the future of the labeling and packaging industry. The focus will be on sustainable solutions, with an emphasis on eco-friendly materials and processes. Digital transformation will be another key trend, as companies continue to adopt cutting-edge digital printing technologies to enhance efficiency and customization. Additionally, there will be significant innovations in flexographic printing, highlighting the latest in solvent-wash and water-wash flexo plates. We are excited to showcase these trends and demonstrate how TechNova’s comprehensive range of products can help businesses stay ahead in this rapidly evolving market.’

Booth E40

Texyear promotes hotmelt pressure sensitive adhesives for tapes and labels.

Booth J45

Japan-based, Tsukatani launches its high-range products in collaboration with Lucky Graphics, its distributor in India. The major highlight at the booth is its Pinnacle Die. It has sharp steel-cutting rules to enhance label cutting.

It also showcases Business Form Tools, designed to handle precision cutting required for continuous paper or other materials production. The booth also features the G-Shot round punch.

Booth A18

UV Graphic Technologies exhibits over 350sqm to launch several latest equipment. The company has been working meticulously for the past two years to unveil a gallery of new machinery for the label industry.

The company launches Ultrafex UFO-5, claimed to be the words first triple diameter flexo press with AI Technology. Offering a stable platform with high register accuracy, the 8-color press being demonstrated at the show is running flexible materials from 8 microns to 400gsm cardboard stock. The press is equipped with corona treatment web cleaners hot and cold foil stamping, rotary screen printing and in-line die-cutting. The press also showcases India’s first indigenously developed servo-controlled vary gap system die-cutting labels and IML. The AI features automatic calculation of all tension parameters, pre-register and auto-register. This is said to be the first Indian press with onboard 100 percent defect detection in cooperation with Deco Systems of Italy.

Another new product is Ultrafex EFO 370 8K economical servo driven press with the basic machine of 8-colors costing less than 1 crore INR. The press has a direct drive technology with pre and auto register at a speed of 150mpm. All presses can be equipped with hybrid LED UV systems with chill drums and a host of other in-line accessories.

The Dominator Ultraflex True Digital hybrid press made in association with Domino supporting two UV flexo stations and the 5-color Domino N610i-H, Hybrid digital engine is displayed for the first time in the Indian market. The press is printing live digital images.

Ultraflex UDF-370, is said to be India’s first semi and full rotary finishing press with two flexo print units, die-cutting, digital printing and digital foiling capabilities. The UDF 370 can run full rotary and semi rotary with precision and fast setup time.

Ultraflex USR+ slitter rewinder, another new launch, comes with fully indigenous 100 percent defect detection in partnership with Lucid Imaging.

On display is the Ultraflex VPM-700 AF video plate mounter with quick loading and auto focus technology and precision mounting of plates. The pony IML die-cutting machine with in-line conveyor and stacking for IML die-cutting. The press demonstrates high-speed IML label punching. The Pony IML can also be used for die-cutting of pressure-sensitive labels with a snowball waste wind system already in place.

UV Graphic also demonstrates the high-speed Pony flatbed hot foil stamping, embossing and die-cutting machine with speeds of 20,000 IPH or 250mpm with integrated waste rewind and 100 percent inspection for foil stamping and die-cutting. The company also demonstrates Core Max 2000, a high-speed automated core cutting machine with multi program function.

Also on display is reportedly India’s first in-line roll-to-roll flatbed silk screen printing machine with digital foil embellishment for high-speed screen printing and embossed digital cold foil.

Booth E8

Vetaphone, which is represented in India by Weldon Celloplast (Hall 10 Stand E8), demonstrates corona treaters on the UV Graphic Technologies stand (A18), and on the Domino stand (A22) where it is mounted on a digital press fitted with a UV Graphics flexo unit.

Holger Selenka, Vetaphone area sales manager for Asia Pacific, commented: ‘The Indian sub-continent, with its annual growth rate in label printing of around 10 percent, is a key area for Vetaphone in strategic terms and we are looking forward welcoming our existing users and meeting new customers along with our friends and colleagues on the Weldon Celloplast stand.’

Booth K22

Vinsak has confirmed to showcase its label embellishment and finishing machine, Label-Decore, at the upcoming Labelexpo India 2024. The machine offers embossing, digital foiling, cast and cure effects, variable data printing and more. It can be modified as well according to customers' demands.

In addition, visitors can also see AB Graphic International’s Digicon Lite, live in action at the Vinsak booth. Digicon Lite is a compact digital finishing machine available in both rotary and semi-rotary configurations. It’s a good option as an entry-level machine for converters who want to add capacity or just venturing into label converting.

Attendees can also learn about Vinsak's products and technologies enabling brands across sectors to elevate their packaging, streamline processes and meet environmental goals.

According to the company, the Indian economy is undergoing a transformative shift, with the next decade being poised for rapid economic growth in rural areas. It expects this growth to bring changes in lifestyle and consumption patterns, leading to an increased acceptance of branded products and, ultimately, a heightened demand for improved packaging and labeling.

Webtech International Machineries

Booth G42

Webtech International Machineries unveils its latest fully servo 10 colors flexo label press with a 340 mm working width, specifically designed for the lamitube substrate. The company also introduces a second fully servo flexo label press with the 450mm working width.

Both of these ELS machines are equipped with dual servo motors on each printing station and come with auto registration technology.

Booth E8

Weldon Celloplast displays AstroNova QL 300 claimed to be the world’s first 5-color toner-based tabletop label printer from QuickLabel that enables brand owners to create high-quality labels.

Going beyond the traditional 4-color (cyan, magenta, yellow and black) printing process, the white toner can print white and CMYK in 1200 DPI high resolution in a single pass. This added capability of printing with white toner opens new, creative possibilities in label design and expands the range of label materials to include transparent, colored and metallic substrates. The QL-300 can print labels with permanence, water-fastness and UV resistance.

Harveer Sahni, chairman of Weldon Celloplast, commented: ‘Labelexpo India is the showcase of India’s evolving label industry. The event was earlier just a show where global equipment was displayed to reach out to India’s label converters. In the last few years, it has transformed to become a global arena where the Indian capital equipment, tooling and consumable suppliers are rubbing shoulders with the best in the world to display their technical prowess.

‘It is a must-visit show for the label fraternity. Weldon Celloplast will welcome converters to its stand at Labelexpo India showcasing an array of its offerings that include high-end label printing and converting machines, finishing and embellishing machines as well as a range of ancillary equipment.’

Booth K12

Wink and its Indian distribution partner Technovation showcase advanced die-cutting technology. Under the theme ‘The art of die-cutting', Wink demonstrates how its tools enable the creation of true label masterpieces, embodying the high art of die-cutting.

The German tool manufacturer shows the latest developments in its SuperCut flexible dies. These product advancements include optimized coatings such as MCR Micro Chrome and Non-Stick Premium, which enhance the performance and durability of the SuperCut dies.

In addition, visitors can expect to see a comprehensive range of die-cutting technology, including a complete lineup of cylinders like OptiMag magnetic cylinders or PowerCut solid dies.

Additionally, Wink features the newest developments in its SmartGap adjustable anvil system.

Amit Kate, managing director at Technovation, stated: ‘We anticipate that Labelexpo India 2024 will highlight the growing demand for advanced and sustainable label solutions in the Indian market. There is an increasing focus on precision and efficiency in die-cutting processes, driven by the need for intricate designs and fine details in labels. Additionally, we expect to see a strong emphasis on digitalization and smart technologies, as more companies seek to enhance production efficiency and reduce waste. The shift towards eco-friendly materials and processes is also likely to be a key trend, with many exhibitors showcasing solutions that align with sustainability goals.

‘We are excited to make our debut with Wink at Labelexpo India, bringing our latest die-cutting innovations to this vibrant and rapidly growing market. Our tooling is designed to meet the evolving demands of the Indian label industry, delivering unmatched precision, durability, and efficiency.

We look forward to engaging with industry professionals and showcasing how our solutions can help them achieve their production goals.’

Booth F38

Xsys showcases its printing plate technologies for the tag and label market.

Roy Schoettle, vice president of Xsys APAC, said: ‘The label market in India is expected to grow at twice the rate of the global average, so there’s a lot of potential for flexo label printers. Our mission is to support them in taking full advantage of this great opportunity with our industry-leading prepress solutions along with our robust service offering. Naturally, this means engaging directly with the market at key events such as Labelexpo India.’

The nyloflex portfolio of flexographic printing plates for labels will be a highlight at the show. The nyloflex range is continually improved with new plate formulations designed to meet the ever-changing needs of the market, such as new types of eco substrates, higher printing speeds and expanded application reach.

One example is the nyloflex FTV flat-top dot plate which can be used for printing not only tag and labels but also flexible packaging. Offering consistent print quality with the finest highlight dots, the nyloflex FTV plate reduces complexity at the prepress stage, because it is suitable for both bank and LED exposure. Furthermore, this formulation is less prone to plate swelling and features AIF (anti-ink filling) technology enabling longer and cleaner print runs with solvent-based inks, the company said.

‘We’re looking forward to discussing our celebrated nyloflex flexo plates and the wider Xsys portfolio, including ThermoFlexX plate imagers, Catena plate processing equipment, nyloflex Xpress thermal plate Processor, and rotec sleeves and adapters with visitors at Labelexpo India. As a leader in the industry with a significant installed base across Asia, we understand the great benefits of meeting face-to-face in an environment that is conducive to deep learning and beneficial knowledge sharing,’ Schoettle said.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.