Digimarc explores new barcode territory

Digimarc, a company based in Beaverton, Oregon, created the Digimarc Platform featuring the Digimarc Barcode, which is a way to enhance objects and media of all kinds, including printed products, with a digital watermark that’s imperceptible to the human eye, but can be detected by smart phones, computers and barcode scanners.

Digimarc Barcode is applied to print-ready, color-separated art files. The barcode is a patterned graphic treatment applied to individual color separations in the artwork. Like a traditional barcode, the pattern carries product data, which can be scanned by barcode scanners or smartphones through the Digimarc Discover app or a retailer app with Digimarc software. But unlike visible barcodes that are typically applied to one or two locations on a package, Digimarc Barcode can be applied throughout the entire package design yet is imperceptible to most consumers.

End use applications for the Digimarc Barcode are vast, allowing brands to streamline store operations, optimize the supply chain, engage with consumers, divert counterfeiting and protect their brand. Making the barcode an imperceptible part of the label or package allows for more valuable real estate for package branding and product information and a faster check out.

Digimarc Barcode can carry the same data as UPC/EAN symbols and contain information similar to QR and data matrix codes.

‘The main difference between a UPC barcode or QR code and our code is that Digimarc Barcode is a part of the packaging artwork,’ said Jay Sperry of Digimarc. ‘It’s a very simple way to add value to labels and packaging.’

In addition to labels and packaging, this serialization technology has been used in publishing, commercial photo and direct mail. Digimarc Barcode can even be added to a textile dress and audio files; the latter innovation that earned the company an Emmy. With that in mind, the company calls its product ‘The ‘Barcode of Everything.’

Working with Walmart

When the world’s largest retailer takes interest in your technology, you might be on to something.

Walmart teamed up with Digimarc to roll out Digimarc Barcode on Walmart’s private label brand Great Value and is using Digimarc Barcode on thermal labels printed on fresh foods. Walmart says this will reduce food waste and improve check out efficiency by reducing the product labels that are crinkled, smudged, wrapped around edges or fraudulently altered.

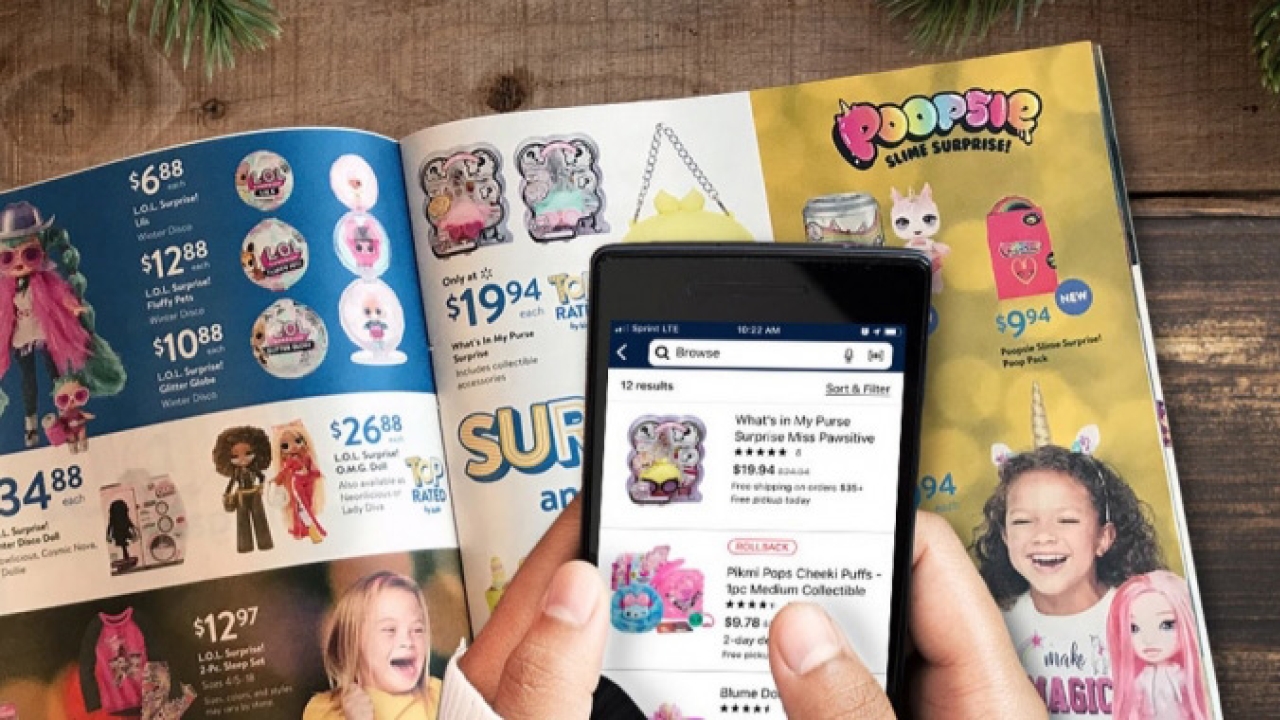

Walmart and Digimarc also paired up for a holiday promotion that truly bridges the digital and printed worlds.

The retailer activated its seasonal toy catalog with Digimarc technology, so users can ‘Scan and Shop.’ Consumers can scan the catalog’s pages with a Walmart consumer app and shop for and hundreds of toys directly from the page. This promotion was included in 35 million printed catalogs available in Walmart’s nearly 4,800 US stores.

Print process

Digimarc Barcode is compatible with flexo, offset and digital printing process. It is applied to an existing art element by software plug in within Adobe Illustrator or Photoshop. The code is added to one of the process colors; typically, cyan since that color offers the highest contrast. Digimarc Barcode is applied after color separation so printers don’t inadvertently remove the watermark.

While challenges do exist in the process, they are not impossible to overcome. Printers are warned not to perform any color corrections or image scaling on enhanced files, and do not reuse any enhanced design elements across multiple SKUs. Color correcting the file could compromise the scanning performance of Digimarc Barcode or make Digimarc Barcode visible at unacceptable color levels.

In flexographic production, plates cannot be shared between SKUs because plates are processed with Digimarc Barcode would result in multiple product codes on a single package and errors when scanned.

Other variables like color, ink density, dot gain, registration and image quality can potentially impact Digimarc Barcode performance.

Digimarc currently doesn’t have a solution for images that require a true white, but the company comes close with a white that’s got a slight mint tinge to it.

Digimarc has plenty of resources on its website regarding print quality control for printers and pre-press operators. Sperry said: ‘We want to educate printers, so when a job comes to them with a request for Digimarc, they’re educated on how to use it.’ Digimarc is a publicly traded company that has invested $150M USD in R&D since 2012.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.