Bobst to launch several technologies at drupa

The company will showcase its latest advancements across flexible packaging, labels, folding carton and services.

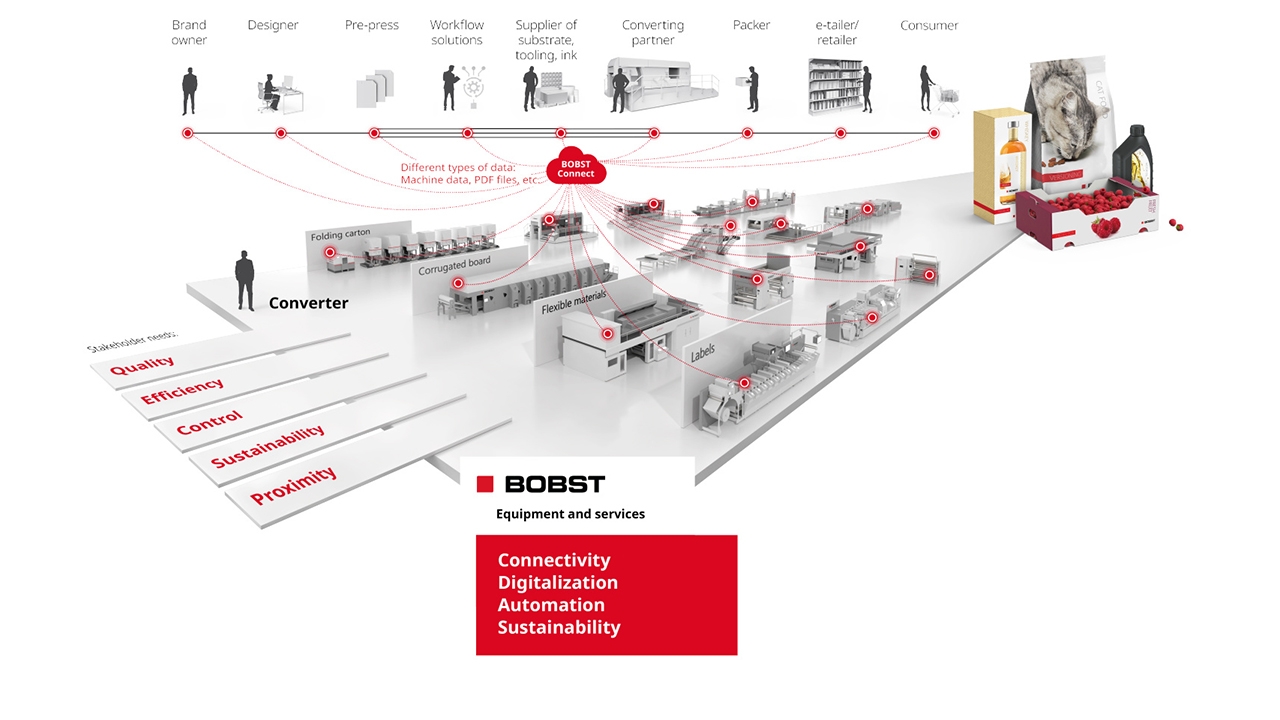

Bobst has confirmed its latest advancements across flexible packaging, labels, folding carton and services will be showcased at drupa 2024 to help its customers to thrive in the current and future packaging environment.

At drupa 2024, visitors to the stage area will have the opportunity to find out how Bobst is bringing its vision to reality through a live-show experience on a ‘concept machine. Through key technologies along the end-to-end production process, Bobst’s industry storylines will be featured.

‘We have made great progress with our vision to shape the future of the packaging world based on the pillars of connectivity, digitalization, automation, and sustainability,’ said Jean-Pascal Bobst, CEO of Bobst Group. ‘Now, with an extensive portfolio of solutions that answer our clients’ needs, we can tailor our offering to them based on their evolving requirements over the years to come. Our latest solutions announced today, embed machines and software with the aim to increase performance, complementing our global offering beyond machine operation, helping us all to build towards a more connected and sustainable future.’

The company has launched two major new features for Bobst Connect, a cloud-based digital platform, which improves productivity. Workflow with Job and Recipe Management empowers customers to integrate Bobst machines in their production and design workflows and benefit from bi-directional job and recipe data synchronization for fast set up and increased productivity.

The new Energy Monitoring feature allows customers to measure their energy consumption and costs in real time. By collecting data across various jobs, settings, and connected machines, and together with industry leading Workflow and Automation Partners, Bobst helps its customers to drive efficiency improvements and cost savings.

The company has also announced it will develop Bobst Application Management across all industries. It is a hands-on innovative consulting service focusing on workflow automation, color and process optimization, end-to-end converting improvements as well as regulatory compliance, addressing the needs of converters and brand owners.

The company has stated that all new machines purchased in 2024 will benefit from at least between 10 and 20 percent efficiency and productivity improvements, from reductions in waste, substrate and energy usage.

In the flexible packaging space Bobst will introduce smartGRAVURE, said to revolutionize the gravure printing process with elements of automation and digitalization. It helps to overcome the important set-up time and tuning required with gravure printing, which require high level operator skills. With automated color management, digitalized set up and controls, and connectivity with Bobst Connect, smartGRAVURE will increase productivity and output consistency, reduce downtime and complexity, and offer considerable sustainability benefits.

The company will also showcase the new Bobst AI-driven intelligent Metallizing Assistant representing a breakthrough in machine integrated process expertise for vacuum metallizing.

Also on show will be new Expertlam 900, a multi-technology coater and laminator, which is configurable in different forms, making it highly flexible both as both a laminator and a coater.

In the labels industry, Bobst aims to simplify label production by taking connectivity and digitalization to the next level by providing new technologies supporting closed-loop workflow ecosystem from pdf to twin pdf to boost productivity, ease of use and sustainability. The features will allow label converters to accelerate job preparation, with faster job completion less dependent on operator skills, and with a more connected production floor, thanks to a range of new BOBST Connect and pre-press features.

Bobst has optimized its workflow leveraging oneECG, enabling digitalization of color information to reach the highest color consistency between digital and flexo. Customers can easily allocate orders to the most suitable technology, optimizing machine utilization and profitability while reducing waste and increasing overall output.

In the folding carton industry, Bobst is empowering zero fault packaging with Expertcut 106 PER, the new generation die-cutter, which increases performance up to 20 percent with increased throughput and positive sustainability impact. It comes equipped with new functions such as the Accuplaten - a new system that will drastically reduce the patching effort during setting and increased running speed.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.