Dutch converter installs first Durst Tau 150 inkjet press

Durst, a manufacturer of digital inkjet printers for wide format graphics, ceramic tile, flooring and label markets, has installed the first Tau 150 UV inkjet press at Dutch label converter Omnilabel for beta testing.

Based in

Because of an increasing demand for short runs and jobs with added value, Omnilabel's Mark Eshuis, Ingrid Smudde-Eshuis and Michiel Smudde evaluated various digital label press systems to find the best possible option that fits their current requirements but should also offer good potential for future growth.

‘After evaluating a number of different suppliers and technologies,’ said Mark Eshuis and Michiel Smudde, ‘we decided to invest in the Durst Tau 150 because the combination of printing method, printing quality and web widths suits perfectly to our existing workflow.’

The Tau 150 covers web widths from 10cm (4”) to 16.5cm (6.5”) and utilizes liquid UV ink technology. The system reaches a throughput speed of close to 50 m/min (160 ft/min). Building on its product offerings in the photographic market, Durst’s Tau 150 delivers an apparent resolution in excess of 1000 dpi using grayscale inkjet print head technology from Xaar. Durst’s proprietary UV inkjet technology features CMYK ink colors plus white as an additional configuration option. A broad range of standard substrates are supported without the need for pre-treatment and post-treatment.

Lower production costs are achieved thanks to affordable ink-only cost models – users pay only for the ink they use. Tau inks are available directly from Durst in five liter containers with an easy and secure ink refill system. The Tau inks have been specially formulated to provide the broad color gamut demanded by the label industry.

The Tau 150 is delivered with pre-press software from EskoArtwork, with built-in RIP, substrate calibration and color management, and an optional Variable Data Printing (VDP) module offers full label-to-label variability.

Helmuth Munter, segment manager label printing at Durst, commented: ‘Digital technology is one of the most exciting areas in label printing and converting today, impacting on everything from pre-press to printing, personalization and finishing, offering huge potential for new products and services in a rapidly changing market place with an increasing demand towards personalized custom products in short run. We are very glad to have Omnilabel as our partner for the first Beta installation of our new Tau 150. The coming months will be a very exciting time for Durst and Omnilabel and we are convinced that this cooperation will lead to success for both parties.’

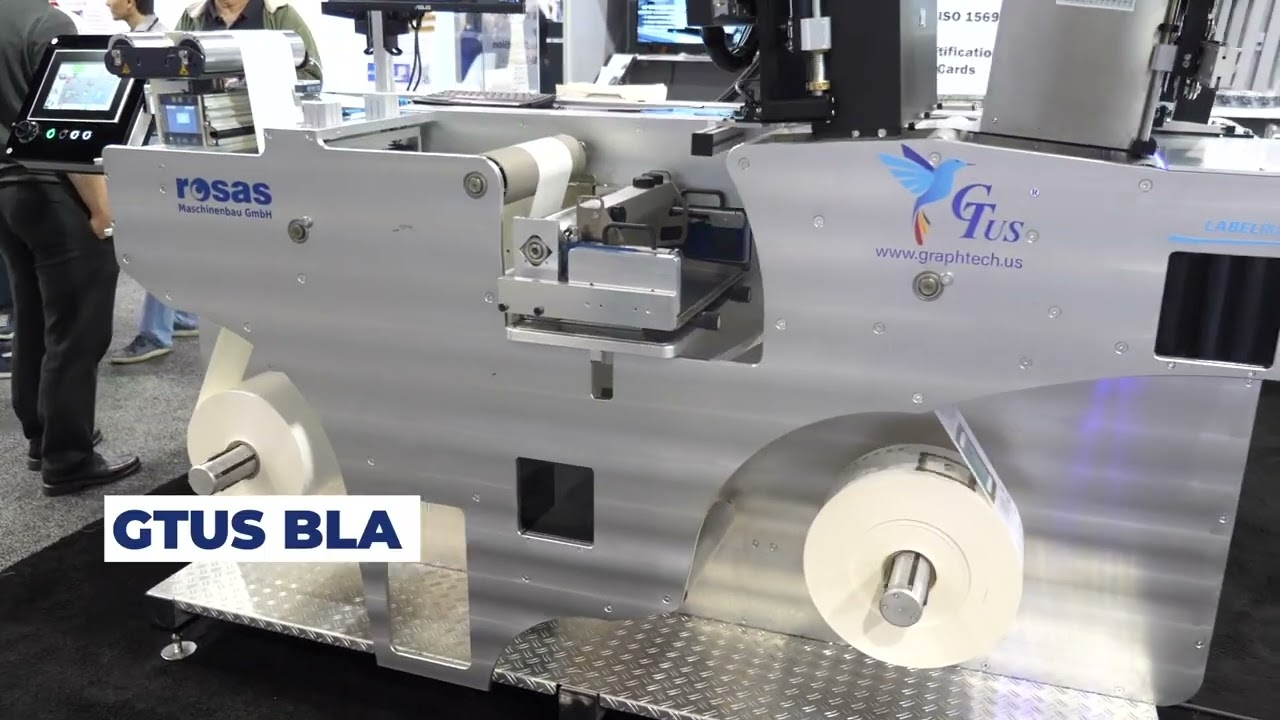

Pictured: Mark Eshuis, Ingrid Smudde-Eshuis, Michiel Smudde and Marcel Klein Herenbrink with their newly installed Tau 150 UV inkjet digital label press

Click here for more stories about Durst on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.