Abbott Label invests in ABG’s RFID converting equipment

RFID equipment helps US-based converter to efficiently and accurately integrate this technology into labels.

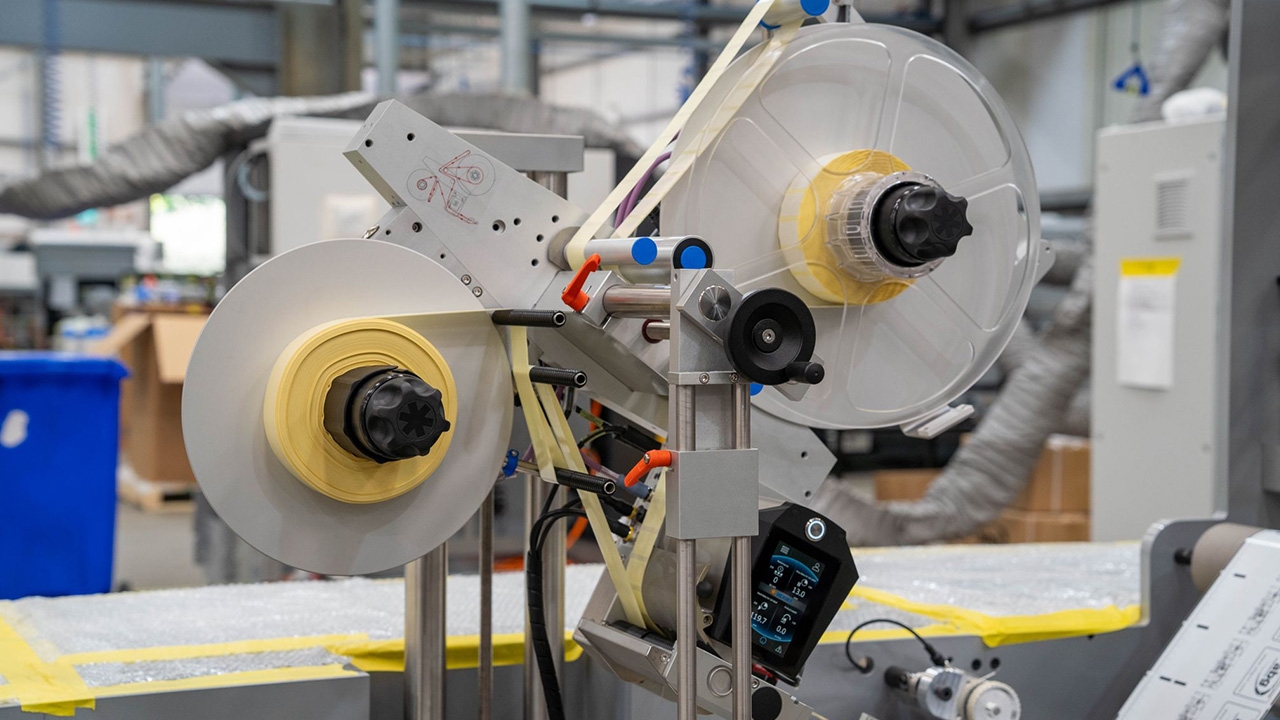

US-based printer Abbott Labels has invested in a 13in (330mm) RFID converting line provided by ABG for its new, specialized converting plant in Nashville, TN, to increase its production capabilities significantly.

ABG said RFID is transforming industries by offering product tracking and identification through a combination of microchips, antennas and RFID readers. It allows for hands-free asset tracking, thereby making processes faster, more accurate and more cost-effective.

As demand increases, companies such as Abbott Label, a US-based label manufacturer and long-time ABG customer, are significantly investing in RFID. Emphasizing the increasing importance of this technology across industries, the company recently announced the opening of a specialized RFID converting plant in Nashville, Tennessee.

The company currently operates five ABG machines. The latest ABG investment, a 13in (330mm) RFID converting line, represents a significant increase in production capabilities. The system is designed to handle high-speed RFID inlay insertion across multiple substrates, label sizes and packaging applications.

Mark Davenport, RFID plant manager at Abbott Label, said: ‘I feel that it’s the highest-producing, fastest solution in the market today. ABG’s equipment is rock solid. All the equipment I’ve bought over the last 24 years is still efficiently running today.’

Converting machines like those in the Abbott Label facility are bespoke RFID lines engineered for large-scale production. These systems support multiple lanes and varied web widths, with modular designs that can be customized to specific operational needs, ensuring flexibility and scalability in RFID label production.

ABG also offers Omega Ti200, an entry-level system designed to insert RFID and EAS tags into labels in a single pass and process up to 1,000 labels per minute. It is suitable for businesses entering the RFID as it has advanced features such as anti-static technology to minimize dust attraction and dual web guides for superior web control.

‘ABG’s advanced RFID solutions help our customers stay ahead in this rapidly evolving market,’ added Matt Burton, ABG’s global sales director. ‘By offering a range of entry-level machines alongside highly customizable systems, we actively support our customers in adopting RFID technology whilst offering increased efficiencies and the reliability associated with ABG solutions.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.