Chengdu grows with Bobst flexo presses

Chengdu runs three Bobst narrow web flexo presses which have allowed it to expand capacity and improve print quality

Chengdu grows with Bobst flexo presses

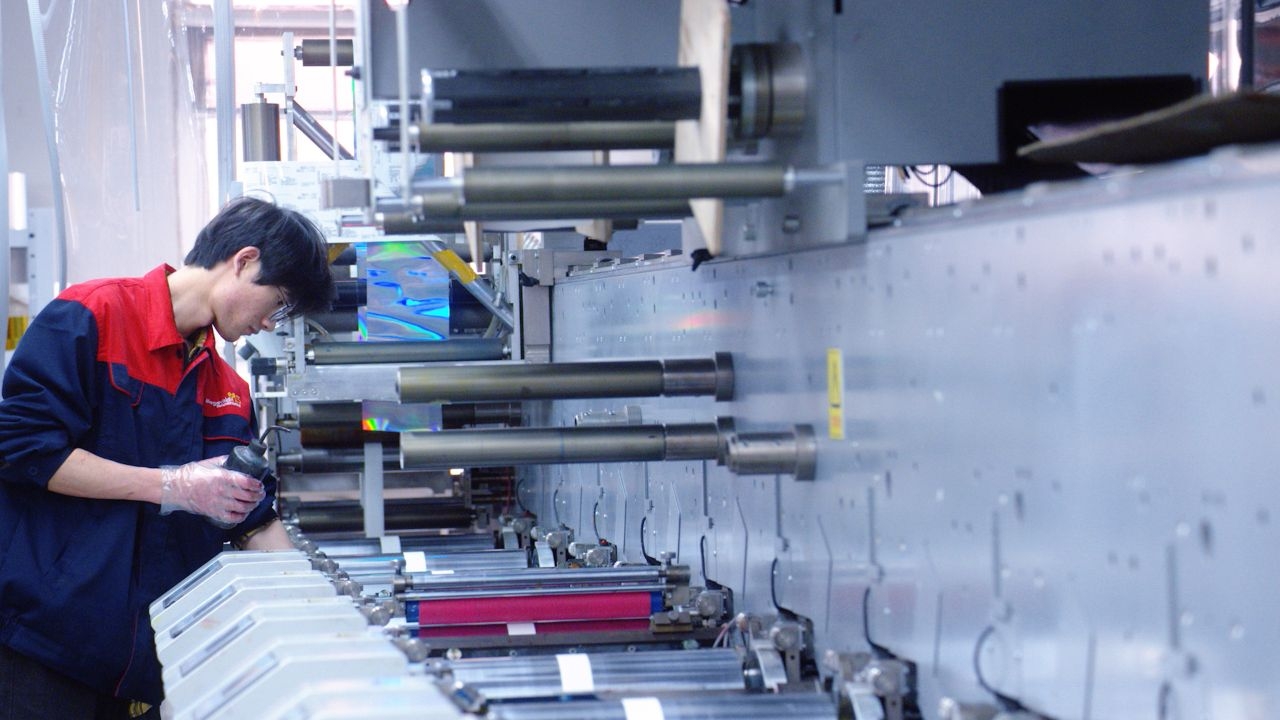

From its fledgling beginnings as a small start-up established in 2005, Chengdu has grown to become one of China’s top 50 label printing companies. Today, the company runs three Bobst narrow web flexo presses which have allowed it to expand capacity and improve print quality.

Founder Liu Jincheng, a mechanical and electrical engineering graduate, had a passion for graphic design. He entered the label industry in 2003, establishing Chengdu Megavision with three friends. Originally printing labels for veterinary drugs, the business expanded to include various segments like food, pharmaceuticals and beverages. Jincheng emphasized the company's focus on design, innovation and understanding customer needs as the key to success.

'From the very beginning, we did not define Megavision as a label converter, but as a service company with design concepts and innovation awareness that add value for customers. We use design as the basis to understand customers’ needs and to solve their pain points. Being able to quickly understand their corporate concept and design requirements for labels, and then produce products that are beyond their expectations, may be the key factor for Megavision’s achievements today,' he explained.

Some 10 years ago, Jincheng made the decision to move from letterpress printing to flexo technology. Between 2012 and 2019, Chengdu Megavision installed three flexo presses from Bobst.

'At the time, letterpress was a popular printing method for labels, but it could not meet the demand for high production capacity and short delivery times. By chance, I began to learn more about flexo printing and got to know Bobst. I discovered that the advanced capabilities of Bobst presses, such as high capacity and fast job changeovers, matched our business model perfectly. Moving from letterpress to flexo printing seemed a good choice for us,' said Jincheng. 'Before finally deciding, we spent a lot of effort examining the equipment closely and, in the end, chose the Bobst Expert M3 press after careful consideration.'

He went into more detail, 'Looking at the equipment structure, Bobst’s flexo presses use the flower flexo head design and have a short web path. It performs automatic pressure adjustments and dynamic job changes in one minute, which fully match our needs for more varieties and shorter runs. At the same time, the HMI touchscreen interface is very intuitive, allowing smoother operation. The most important point is the high production efficiency with the press achieving 180 m/min high-speed printing, and the quality is very stable.'

Touching on the machines in more detail, Jincheng said: 'The first Bobst Expert M3 flexo press was bought to increase production capacity, while the second and third Bobst Master M5 flexo presses were installed to upgrade the label quality. From simple process to multi-process inline production, our Bobst equipment has supported the rapid development of Megavision, because the machines adopt a modular and flexible design with flexo, screen-printing, foiling, die-cutting and foiling and other modules that can be combined. This also means that in the future, through the powerful functions of this equipment, we can present customers with more abundant and wonderful product effects and satisfy diverse customers’ demands.'

With the help of its Bobst flexo presses, the company plans to participate in national label printing competitions and expand its business beyond Chengdu and Southwest China.

Regarding future development, Jincheng has always had a clear idea, 'No matter how the times change, our pursuit and dream of labels is always the same, starting from R&D innovation to product design, we will focus with perseverance on creating more value for our customers with more professional and customized solutions.'

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.