Erhardt+Leimer at Labelexpo Europe 2023

New rotary drives for print inspection

Erhardt+Leimer will exhibit new rotary drives and the new generation of the Smartscan print image inspection system at Labelexpo Europe 2023 taking place in Brussels from September 11 to 14. Also on the E+L stand D45 in hall 4: systems and equipment for web guiding, web tension control and print monitoring.

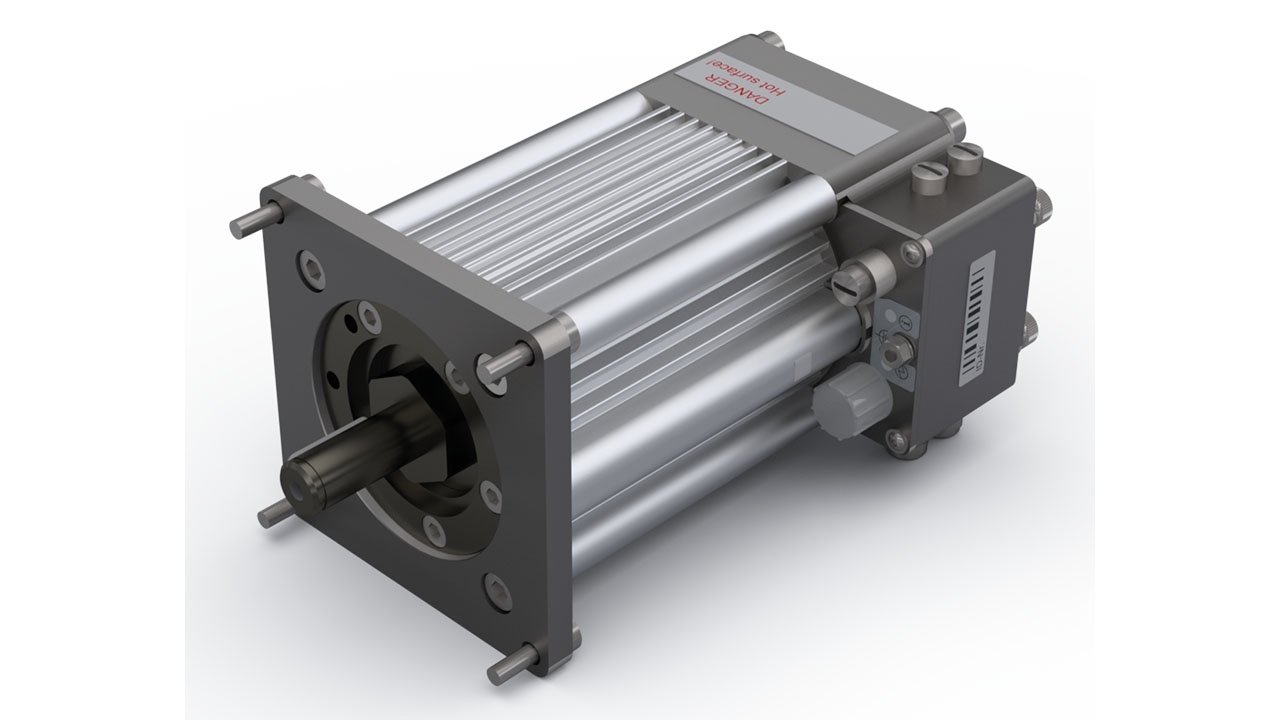

E+L has recently added rotary actuating drives to its actuator product range. The motors of type AD 11 and AD 12 marketed under the EL.Motion brand are ‘intelligent’ drives with an integrated controller. The drives can be used for position control, speed control, or torque control and are particularly suitable for applications where very quiet operation and long service life are key.

Two external limit switches can be connected directly to the drive. The combination of distributed intelligence with a dedicated interface concept allows a decentralized drive topology to be implemented. Erhardt+Leimer makes a wide range of communication standards available for these drives. The AD series comes with EL.Net technology, which allows control tasks to be implemented without any need for an external controller. E+L has a large number of sensors and input/output modules available for this. All the drives come with web-based management on board as standard.

This means that when the motor is connected via Ethernet, it can be addressed from the browser of a PC, allowing users to check and adjust settings or query the current status. E+L also offers open access via Ethernet/UDP or certified standard protocols, such as Ethernet/IP, Profinet, and Powerlink.

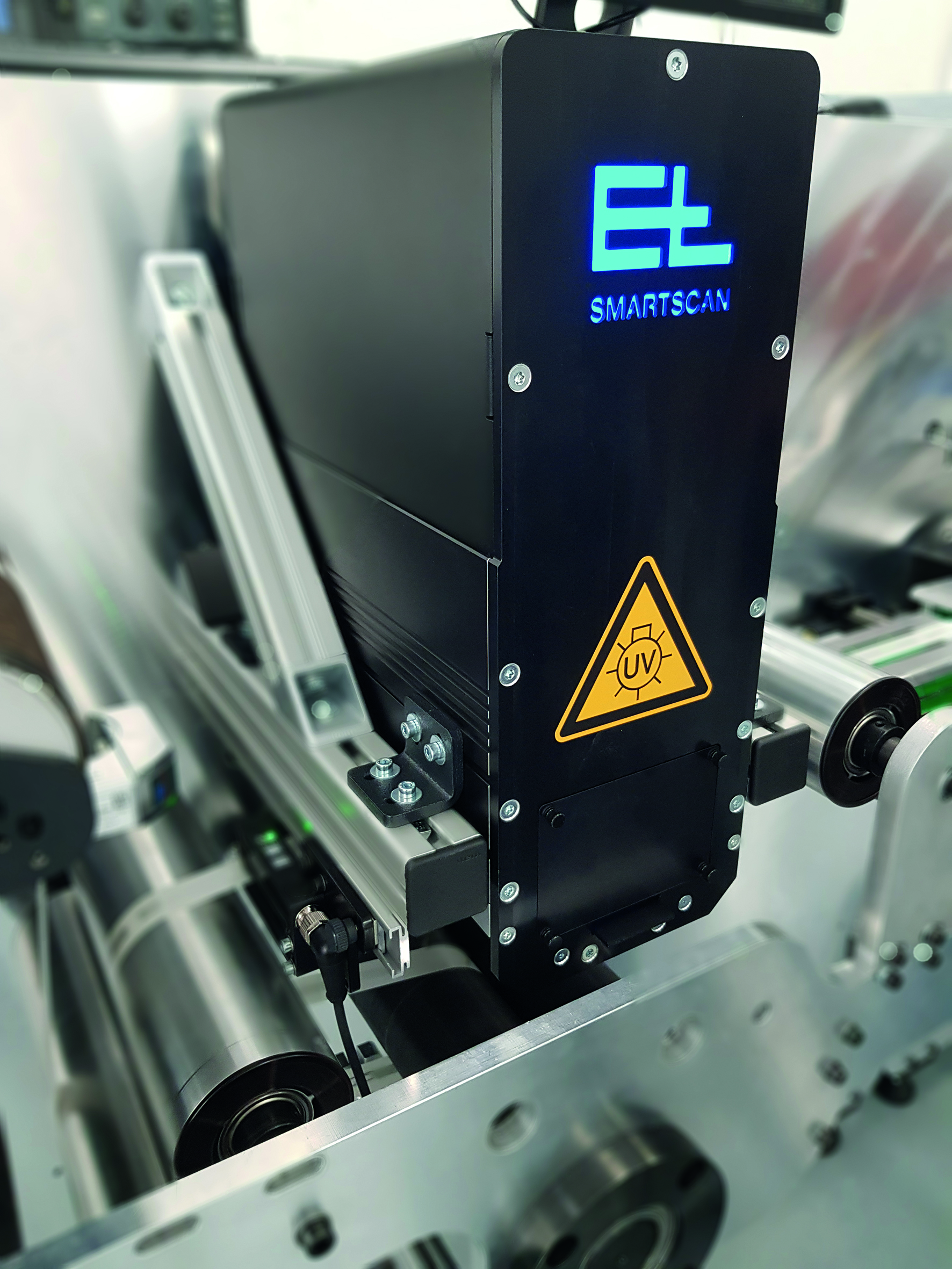

The new generation of Smartscan can be installed in the familiar way on printing machines and rewinders. Smartscan – or the MIS2 model to be more specific – is now faster and more compact, and it has a new design. On the variant with 2K resolution, the company has offers speeds of up to 600m a min. But the 4K variant is catching up, and is now reaching speeds of up to 400m a min.

The reflection module for displaying reflective, usually metal-coated materials or finishing foils (such as gold, silver) is now included as standard. The same applies to the exchangeable background panel, which is advantageous for transparent materials in particular.

The height of the camera units has been reduced. A new installation concept makes integration in the printing machine or the rewinder easy. Previously, Smartscan was available with a maximum width of 560mm (22 inches), but with the latest generation E+L now also offers 660mm (26 inches) and 760mm (30 inches).

In addition, the software has been optimized and expanded. New defect detection algorithms spot defects. The same applies to the defect classification system, which assigns defects to categories such as missing label, unremoved matrix, print error, glue joint, or flag. Further defect classes such as hole, barcode or incorrect length are also available.

The tried and tested 200 percent inspection technology will continue to be used. Improvements have also been made to the detection of hole defects and to the illumination of fluorescent materials. But special applications, such as the production of labels with integrated RFID antennas, will also benefit from the new features.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.