Techkon launches ChromaQA with SmartINK

New feature uses AI-driven technology to take the guesswork out of toning ink on press and in the inkroom.

Techkon has launched ChromaQA5 with SmartInk, an AI driven, new feature, that allows users to make precise ink toning adjustments, either on press or in the ink room, without the guesswork or inherent experience.

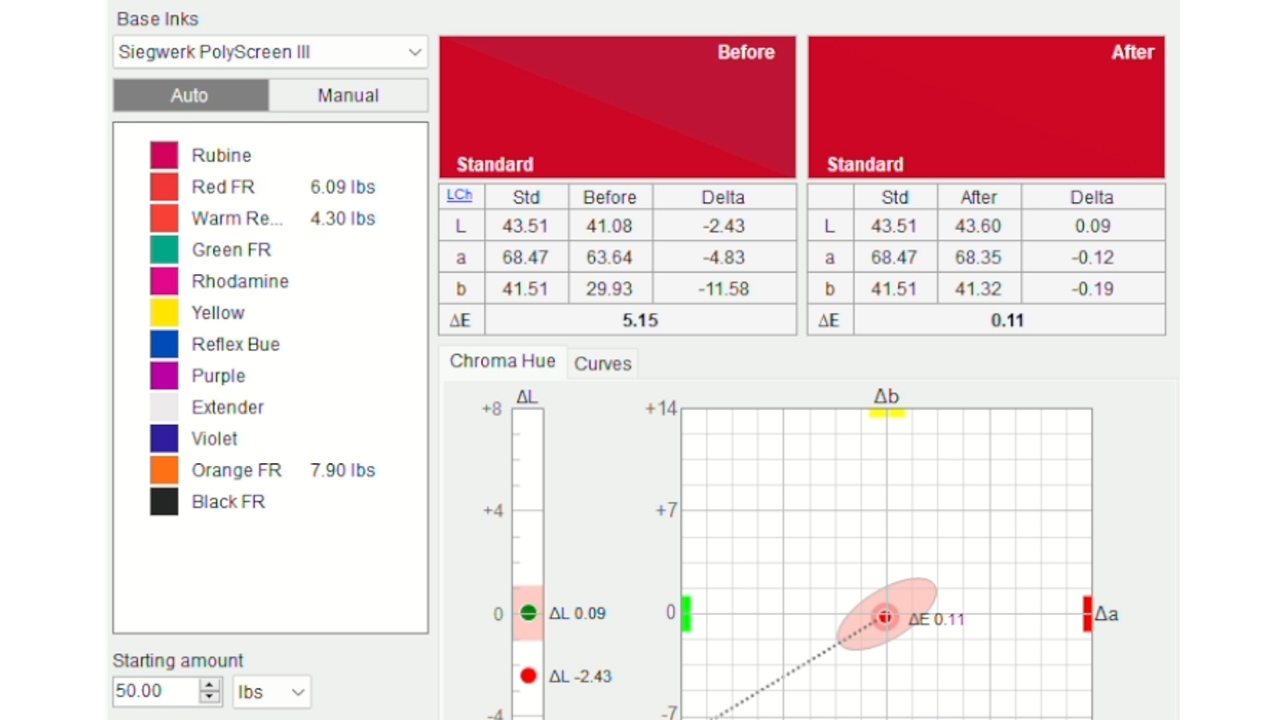

ChromaQA with SmartINK allows users to tone ink quickly and efficiently with just a few clicks. First, users define their specific base ink sets and substrates, a one time-setup to make sure that the AI-driven algorithms are correctly tailored to the specific environment.

From there, whenever ink corrections are necessary to get below a certain deltaE tolerance, the user selects the correct base ink set and substrate combination, sets the starting amount of ink in the bucket or on press, set the maximum desired amount of ink to add, clicks button to run correction calculations and makes the required ink recipe corrections.

ChromaQA with SmartInk provides substantial benefits and cost savings for a variety of applications. It significantly reduces make ready times, allowing for increased billable press-time, substantially reduces wasted materials, both in shortening make-readies and in increasing the work-off of waste ink, thereby reducing cost while at the same time improving the sustainability footprint.

The new feature is a viable substitute for full blown ink formulation software at a fraction of the cost, while being much easier to learn and use and can help address skilled labor shortages in the industry as it empowers anyone to perform ink toning on press efficiently and without prior experience.

Jon Whalen, assistant production manager at Interflex, said: ‘In the past, if you didn’t have an extremely skilled laborer, you would have long color match times and a lot of difficulty in keeping the press running. Now, with ChromaQA and SmartInk, we have a lot of young guys that are starting out fresh and it’s helping them to understand how that base and pigment impact the overall color of the product. Overall, that's equaled up to USD 20,000 savings just in press time alone in only four months. That’s not even counting up my ink room’s time. Plus, our workoff program has become a lot easier, too. Our workoff numbers are over USD 50,000 a month now.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.