Helvetikett invests in EyeC Proofiler 600 DT inspection system

Swiss label converter improves its production efficiencies and ensures compliance with the highest standards.

One of the leading Swiss label converters, Helvetikett has implemented the new EyeC Proofiler 600 DT inspection technology to improve its production processes and ensure compliance with the highest standards.

The company decided to replace an existing EyeC system with a successor model when a requirement for mandatory off-line inspections in quality assurance arose. The decision was also influenced by introducing various ISO certifications that required specific qualities of the new device.

‘One of our core competencies is to quickly identify opportunities for improvement and take the necessary measures to expand our technological leadership further,’ said Pascal Stieger, head of quality management at Helvetikett. ‘Accordingly, we knew what requirements the new device had to fulfil to avoid potential problems in quality assurance.’

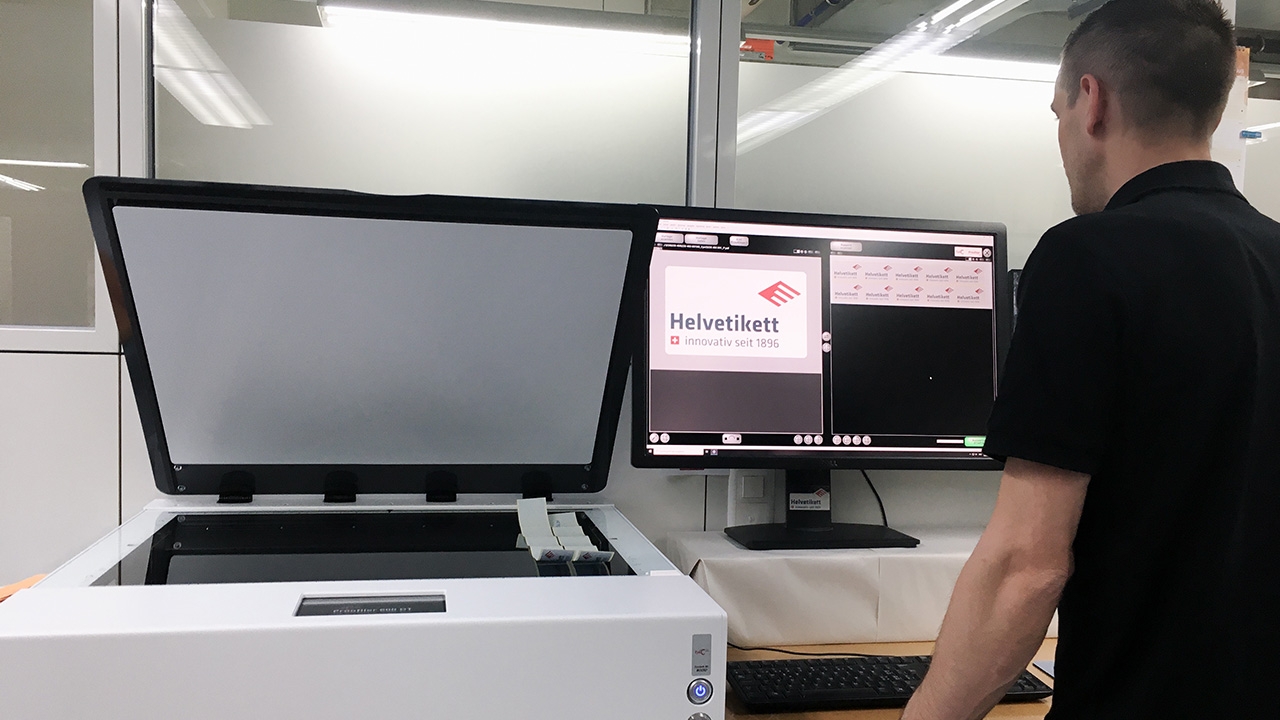

After extensive research and evaluation of various options, Helvetikett chose the EyeC Proofiler 600 DT scanner-based system in A2 format due to its ease of use, time savings in the inspection process, and the expertise already gained from years of using the previous system.

‘EyeC's familiar operation and competent service were decisive factors for us as an existing customer. The personal contact and support from our contact person Christian Hauswald also convinced us,’ added Stieger.

The EyeC Proofiler 600 DT is used daily by Helvetikett employees for quality assurance. The system enables them to document off-line inspections customized to specific customer requirements. The Proofiler 600 DT combines the power of intelligent software with a high-resolution scanner for fast sample inspection. Employees scan the production sheets and compare them with an approved master file.

‘The inspection is straightforward, fast, objective and reproducible,’ said Stieger. ‘The system also complies with the ISO certifications and regulations required by customers, such as ISO 9001, ISO 15378 (GMP) or FSSC 22000.’

Helvetikett said it has already achieved significant advantages in its inspection processes. Compared to the previous model, the inspection cycles have become around 40 percent faster, showing considerable time savings for employees and increased efficiency for the production process.

In addition, the system enables accurate foreign language and code checks, including 1D and 2D codes, further increasing the flexibility and precision of the checks. The EyeC Proofiler 600 DT also allows for more precise checking of multi-layer samples, reducing the error rate and ensuring all products meet Helvetikett’s standards.

‘The collaboration with EyeC has not only had a positive impact on quality assurance but has also improved the entire production chain,’ stated Stieger. ‘This rapid success was primarily due to the simple and familiar operation and the competent training provided by the responsible EyeC service engineer Franz Manegold.’

Helvetikett plans to further expand the use of the EyeC Proofiler 600 DT. In collaboration with EyeC, additional training courses will be offered to employees to further optimize quality assurance and exploit the system's full potential.

‘Helvetikett is characterized by the courage to develop and strive for improvement constantly. In EyeC, we have found a partner with its finger on the pulse who shares our values and enables us to guarantee our long-term success in the future,’ concluded Stieger.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.