Kingfisher Labels invests in 10th Edale press

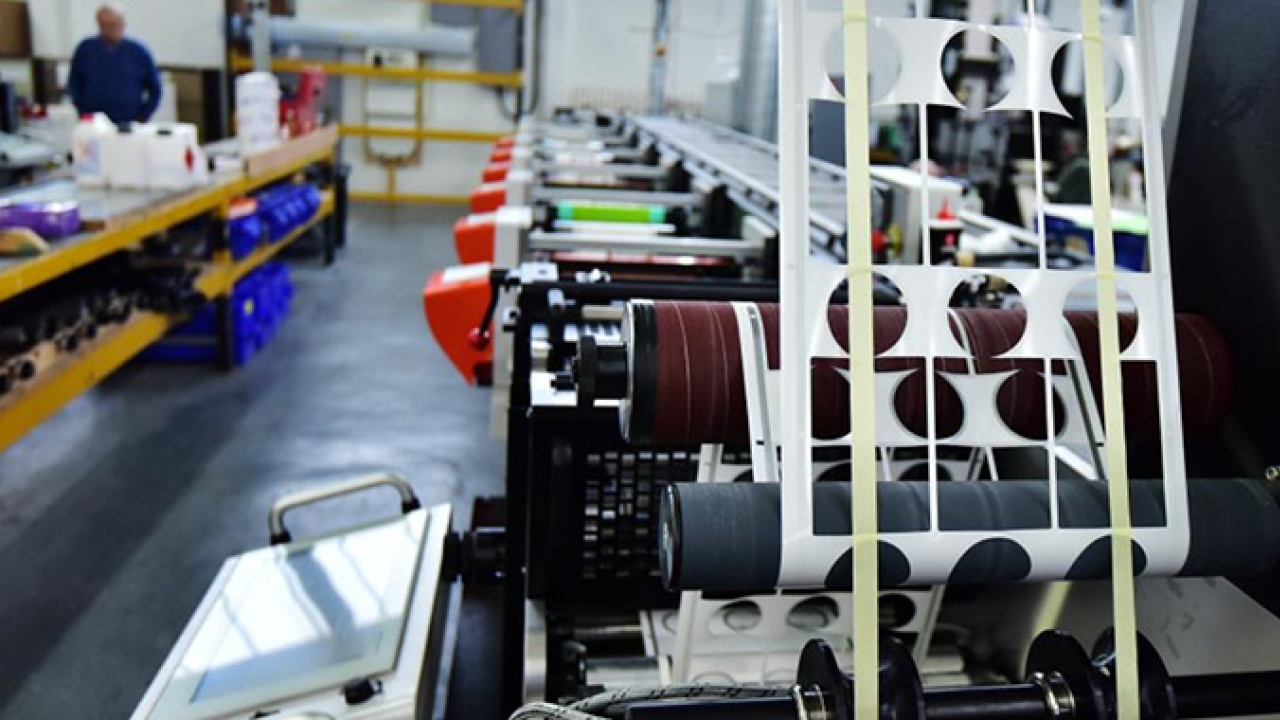

UK-based, family-owned Kingfisher Labels has invested in Edale FL1 Prime, a single-pass label press in line with its ongoing strategy to ensure the company operates the latest technology with the ability to customize the press to meet the growing needs of its customers.

Kingfisher Labels, founded in 1996, is an established brand in the self-adhesive label market and one of the leaders in servicing the food, beverage, and healthcare sectors. Its ethos is built on forging strong relationships with its customers.

The recent investment is a 6-color, 350mm Edale FL1 Prime featuring preregistration and Edale’s unique UNiPRINT technology, ensuring optimal print geometry to produce the highest quality print possible. Jobs can be set in just one web length of material using the job storage feature. Further innovations such as the open architecture of the inking system enable rapid changeovers and precise control over color management.

The investment is part of an ongoing strategy to ensure that the company has the latest level of technology with the ability to customize its press to meet the growing needs of its customers' ever-changing requirements.

After experiencing the benefits of the FL1 Prime first-hand, Kingfisher Labels decided to invest in its second Prime, which will be installed at the end of 2022.

Karl Jackson, production director at Kingfisher, said: ‘We have a great relationship with Edale, which spans many years. For us, Edale found a gap in the market with an affordable, space-saving, and efficient option that allowed us to customize as needed to suit our operation.

‘Our business is diverse and growing rapidly, so we wanted to invest in another machine which could interchange with our existing presses. The FL1 Prime was perfect for sharing tooling, and as the die stations are the same, we can interchange between our FL3s and Prime. This has given us greater speed and operator efficiency, and we pride ourselves on our flexibility and job turnaround for our customers and can facilitate seven to 10 days to delivery.’

‘Kingfisher has exacting standards in terms of its print quality. It had a very clear vision of what is needed in terms of customizing its FL1 Prime,’ added Louise Bailey, business development manager at Edale. ‘We were very happy to work closely with the company to meet its specific requirements. We have a fantastic relationship with Kingfisher and are absolutely delighted that it has invested in its second FL1 Prime since its last installation. The Edale team is very proud that this will be its 10th Edale press. Kingfisher is an extremely valued customer, and we are excited to see what the future holds for it.’

‘When people ask why Edale, it's simple really, we chose Edale because of the family feel, we are a family business and appreciate the respect Edale has for us, and we have the same respect for Edale. Dealing with Edale means you can have a normal conversation; it's easy to talk to each other openly and honestly. Support over the years has been really good, and any issues have been resolved. What more can I say,’ concluded Jackson.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.