Mark Andy delivers more than 30 toner and hybrid presses in Poland

Polish market has significant share in entire sales of Mark Andy’s hybrid presses in Europe

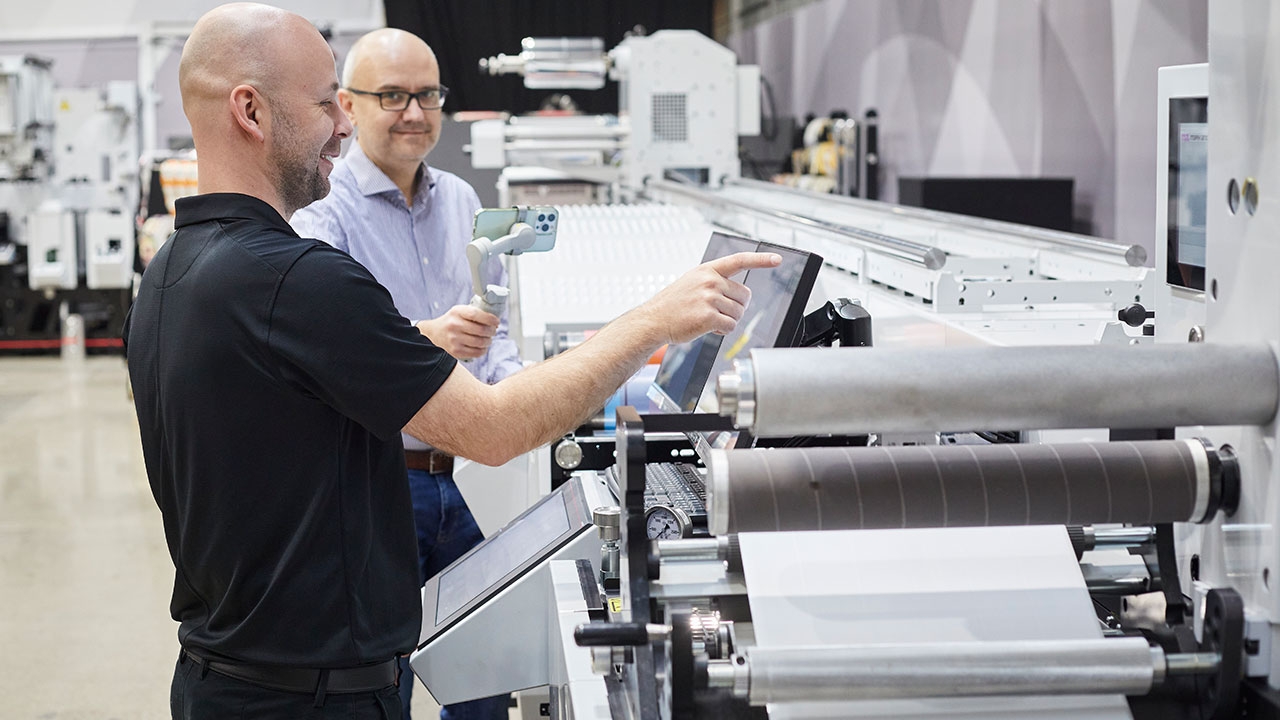

The online live demontration on the Mark Andy Digital Series HD in Mark Andy Poland Technology Center

Mark Andy, one of the leading manufacturers of hybrid presses, has delivered more than 30 toner and inkjet-based hybrid machines to Polish printers and converters, making the company number one among hybrid vendors in the country. The Polish market also has a significant share in the entire sales of Mark Andy’s hybrid presses in Europe.

According to Mark Andy, when digital presses first appeared on the market, they were assumed as a threat to conventional printing. However, market changes, developing technology and opportunities have proven digital technology to be a complementary rather than an alternative one. Several offset and flexo printers looking to grow and meet their customers’ needs have decided to invest in digital presses.

The company is seeing a similar trend with hybrid solutions. Mark Andy has shown increases in the number of hybrid presses sold year by year. Moreover, some of the company’s customers have decided to buy multiple hybrid machines, confirming the maturity, flexibility and comprehensiveness of this technology.

‘Mark Andy’s top priority has always been following customers’ expectations and constantly changing market needs,’ said Przemysław Polkowski, country manager at Mark Andy Poland. ‘As the leading manufacturer of narrow-web presses and with more than 75 years of market experience, we have been conscious of many trends that affect the label market, including the growing popularity of digital printing. In 2017 we installed the first Digital Series and Digital One hybrid presses in Europe. What’s interesting, both pioneer implementations were realized at the Polish printing houses. Our hybrid offer has been constantly expanded and currently, it covers two series of presses based on inkjet and toner technologies.’

According to Polkowski, at the beginning, many customers were unsure about investing in this new technology. Some of them, especially those more conservative, had been using conventional printing for decades and didn’t even want to talk about hybrid and its opportunities.

‘Despite this initial reservation, we’re now observing dynamic sales growth for hybrid solutions. Specific to the Polish market, we have already implemented more than 30 hybrid presses in this country. Moreover, in 2022 we have delivered second or third hybrid presses to the same customers, which is always a special occasion to celebrate. The current dilemma for many printers is not about whether to invest in a hybrid press but rather when to invest for it to be most profitable and impactful on further growth,’ added Polkowski.

According to recent market research ordered by Pekao SA bank, production of the global packaging industry is worth approximately 1 billion USD. Almost 60 percent of global demand is generated by the food and beverage industries. Production structure is dominated by two kinds of packaging: paper- and plastic-based – which cover approximately 70 percent of the industry’s sales. In this context, Poland is quite a significant market, holding third place in the EU in terms of packaging export.

‘During the last two years, our country has increased its export sales, dynamically affecting the rapid growth of the whole national packaging industry,’ notes Polkowski. ‘This includes 2020, a year highly affected by a pandemic crisis. Moreover, last year the Polish packaging market noted a dynamic recovery, including export. As a result, the positive balance of trade in packaging has increased four times since 2010. The above data also implies good results for the label market, which is strongly tied to packaging. We see a lot of new investments in Poland, enabling further growth for our printers. We’re very happy to see many hybrid Mark Andy presses as the first-choice solution of many label converters. As a person responsible for this market in Poland, I’m very proud of our latest sales results.’

Decreasing label runs, demand for new packaging and label designs, a need for renewing and diversifying, versioning, pressure on shorter delivery times and higher quality, a growing number of smaller companies, and manufacturers ordering smaller runs – all these aspects have motivated many printers to change their views on hybrid technology.

‘Hybrid presses enable maintaining current customers, but also getting new ones who have other needs,’ comments Polkowski continues. ‘Moreover, hybrid presses open completely new opportunities for their users. The investment in hybrid generates further growth for label converters and that’s why they really appreciate this technology. In many cases, a hybrid press is a necessity in terms of production profitability. The majority of our “hybrid” customers are very familiar with the technology after its full implementation, so they use the equipment on a full scale, with the highest uptime possible.’

According to Mark Andy’s hybrid users, they achieve at least a 50 percent reduction in waste generated during the production of short and medium runs. They also underline the energy efficiency of these presses as they need approximately 50 percent less energy than a conventional flexo press. Moreover, they generate a minimum amount of ink waste.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.