Muller Martini highlights innovation in web offset for package printing

- Event showcased developments in web offset package printing, and showed jobs being produced on Alprinta V and VSOP presses

- Additional information provided on data handling, CtP, ink and substrates, as well as development and use of stepless, variable size web offset presses

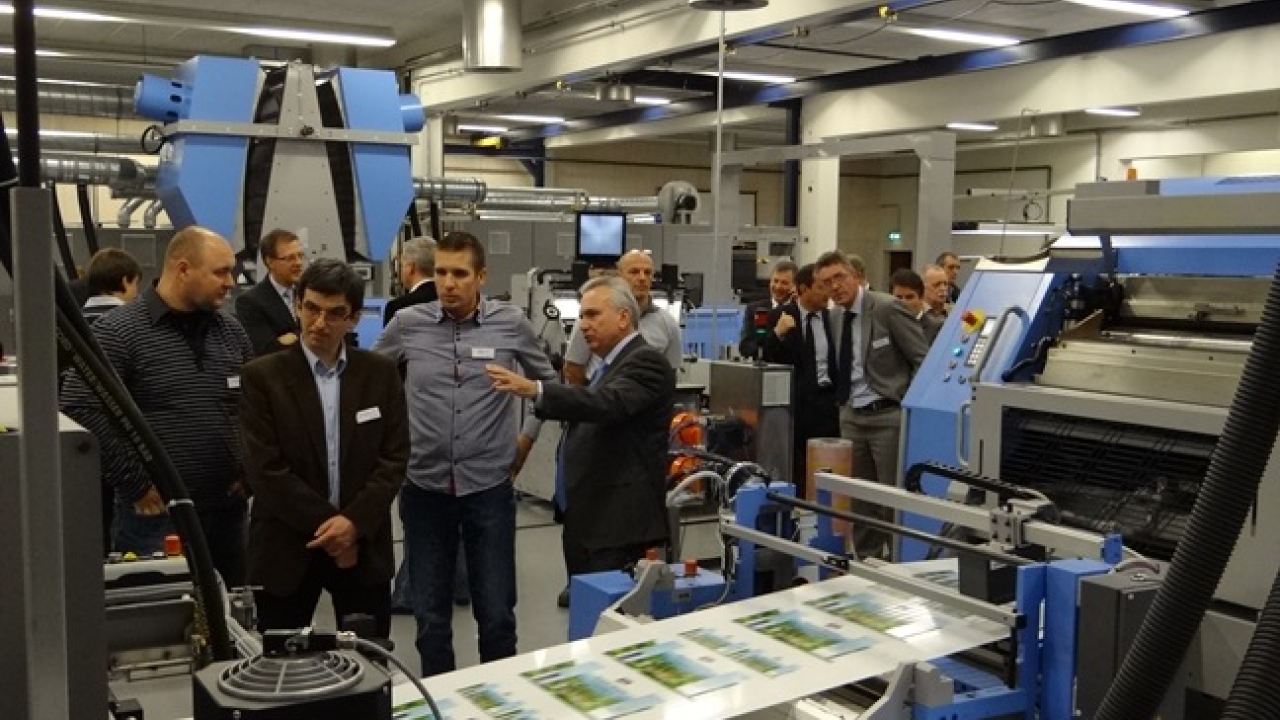

With package printing predicted to grow 23 percent in volume by 2016, Muller Martini invited more than 100 package printers and converters to its training center and demonstration facility in Maulburg, Germany to hear about the latest developments in the field of web offset package printing, and see jobs being produced on two of the company’s presses, an Alprinta V and a VSOP.

According to Muller Martini, packaging printers are keen to find out what the latest web offset technology has to offer, so the event provided an ideal opportunity to present a range of techniques and information to illustrate this, from data preparation to the use of different inks and curing methods available of the company’s presses.

Speaking as a user, Alberto Maria Cavalli, managing director of Constantia Novis in Romania, which installed an Alprinta 74 V three years ago, said he was impressed with the diverse range of applications on offer.

He said: ‘The demand for paper labels is falling but the market for film labels continues to grow.

‘So we set ourselves a goal of staying flexible so that we could develop new products. The Alprinta has allowed us to do this, and has increased our capability across a range of products.

‘Today, Constantia Novis produces labels for various types of packaging, particularly for the beer and beverage industry.’

The seminar also featured presentations on issues such as data handling, Computer to Plate (CtP) technology, working with proven ink systems in the food industry, the use of diverse substrates, and the development and use of stepless, variable size web offset presses, including the printing of polyethylene (PE), which offers new areas of application.

The program ended with demonstrations of Muller Martini’s Alprinta V and VSOP web offset lines. The jobs printed were all challenging, and typified what a packaging printer would be likely to encounter in everyday production. Substrates included PE , OPP (oriented polypropylene), and PET (poly ethylene terephthalat), with the operators showing how quickly the presses can be changed from one job to the next.

Muller Martini said the seminar showcased the advantages of its technology, especially the relatively low cost of producing offset printing plates, and how well its hybrid technology works in combination with flexo to produce high quality print with fast and easy changeovers.

Read more on Muller Martini here

Read more about press technology here

Read more news from across Europe here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.