Atlantic Zeiser announces pack print innovations for pharmaceuticals

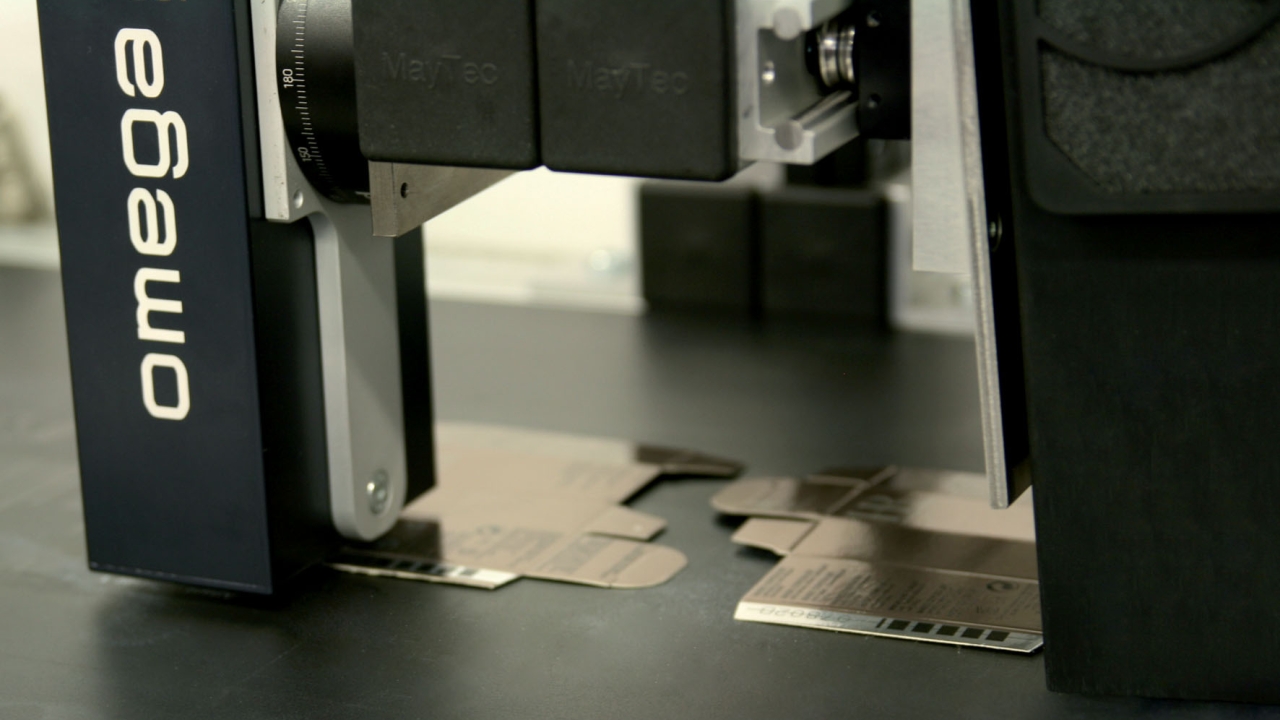

Atlantic Zeiser will showcase its new Omega 20/25 printing module and a new air-cooled LED curing technology at INTERPACK 2011. The print unit and curing system package can be used for horizontal and vertical printing, and has been designed for the special requirements of the pharmaceutical industry. It features a compact design, and offers powerful inline integration components for marking, coding and serializing in late-stage customization, as well as product track and trace and anti-counterfeiting.

The Omega 20/25 is a spot colour DoD inkjet printer, capable of covering printing widths between 20mm and 25mm, the maximum printing width required for adding markings and variable product and production information to pharmaceutical packaging. This includes contents, expiry dates, warning notices, usage and consumption notes, as well as volume information in text and in different languages.

It also offers machine-readable coding of the packaging materials with the corresponding information as barcodes or 2D data matrix. In this process, check codes are printed and can be used for product tracing. The check codes can also be used to tackle the growing grey market in the pharmaceutical sector.

The demand for lower printing widths of 20mm to 25mm is based on the installation options available on existing packaging lines at pharmaceutical producers. As these are generally large-scale systems, there is very little space for marking and coding integration modules. This means a compact design is crucial. To ensure the requisite high quality is achieved, the company has developed a unique air-cooled LED curing solution that hardens the printing ink at speeds of up to 60m/min.The curing system requires no additional cooling units or coolants, and features a design as compact as the Omega 20/25 printer.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.