GM brings nine machines to Labexpo Europe

Danish manufacturer will show its advanced finishing technology for digitally printed labels

GM (Grafisk Maskinfabrik) will bring the full force of its advanced finishing technology for digitally printed labels to Labelexpo Europe 2023 in September. The Danish manufacturer will demonstrate nine machines at the show, all designed to streamline the converting process and empower converters to finish first.

‘We are really looking forward to showing visitors the many innovative ways that our machines can optimize their finishing process,’ said Uffe Nielsen, GM’s CEO. ‘Automation is driving profits and it is the key to growth. Our mission is to build automation into as many aspects as possible, whether that is through technology innovation, like the GM laser die-cutting module, or partnerships with other industry leaders, such as Cerm.’

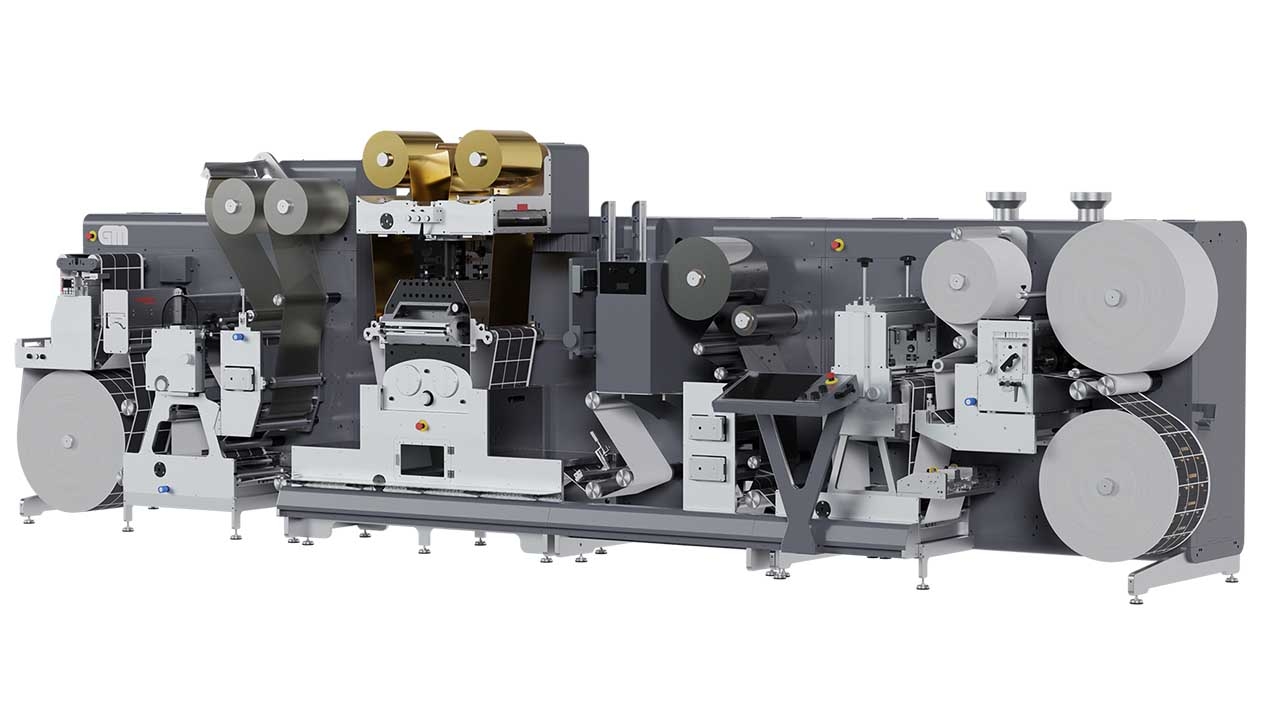

The spotlight on stand 9A40 will shine on the automated DC350Flex+ Wine line for premium label embellishment. Designed for adding value to digital labels for luxury markets, particularly wine, spirits, cosmetics, and beauty, it offers foiling and embossing capabilities and digital varnish effects. The DC350+ Flex Wine features a 50-ton hot stamping module, which uses multiple foil streams. It also comes with an integrated Foil Saver which effectively reduces the wastage of costly foils, while GM’s QuickMount technology facilitates faster mounting of the embossing plates.

DC350Flex+ Wine will feature the DVM350 Digital Varnish Module, which uses the latest inkjet technology for digital embellishment. The module adds spot varnish, high-build tactile effects, including warning triangles and Braille, as well as metallics and holograms, all in one process.

‘Digital varnish and digital foil will shape the future of a highly competitive market in short to medium-run digital label printing,’ stated Uffe. ‘On the DC350Flex+ you get the option to add these capabilities with the fantastic DVM350 Digital Varnish Module, giving you tool-free operation, full flexibility in design, faster job changes, and lower costs. That really is a game-changer!’

Also introducing the addition to the GM line-up: the DC350Flex+.This machine boasts a rotary die-cutting speed of 130m a min (or 80m a min in semi-rotary mode), the DC350Flex+ series offers complete customization options. The DC350Flex+ can perform as standalone operation or integrated with a digital press.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.