Weber Packaging unveils label printer-applicator

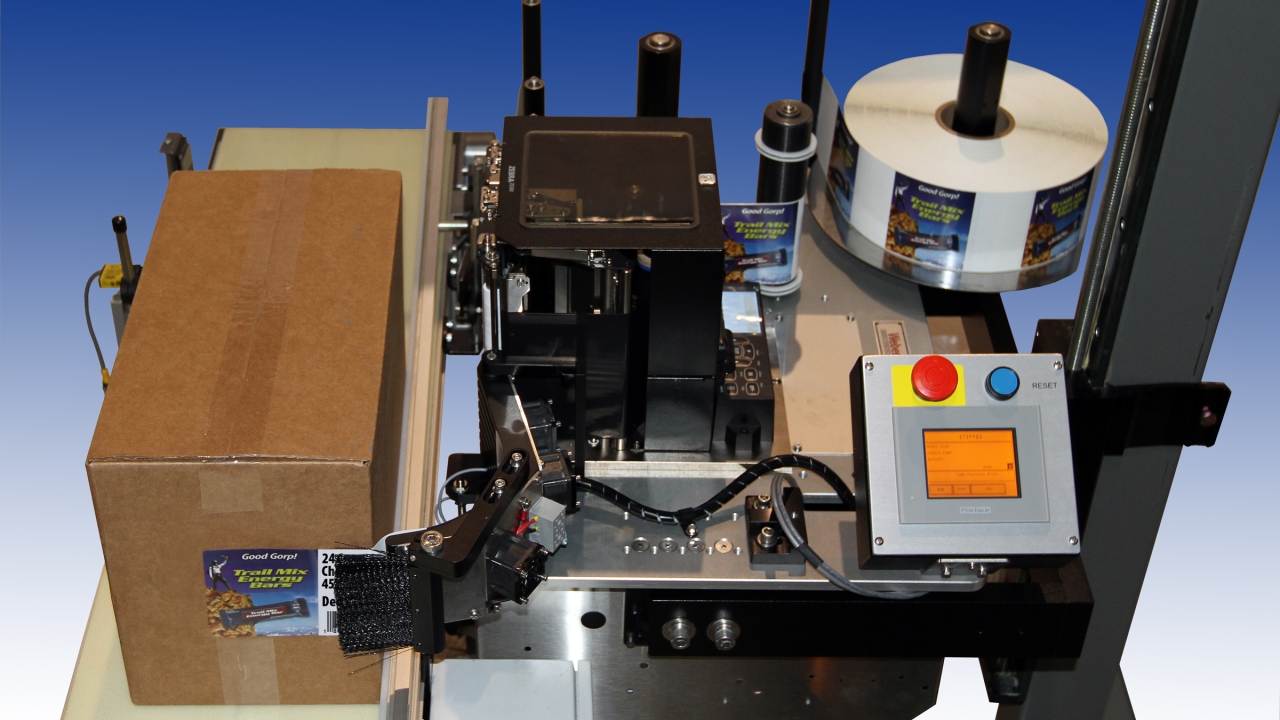

Weber Packaging Solutions has launched its new Model 5300 All-Electric Corner-Wrap label printer-applicator, a unit that saves energy by eliminating the use of compressed air, at Pack Expo on booth S-2440.

The unit prints labels in a next-out mode, automatically removes them from their liner, and retains them by vacuum on an integrated swing arm-mounted pad. Unlike most conventional label printer-applicators, however, the new Model 5300 All-Electric system creates that vacuum with electrically-operated fans instead of external compressed air.

‘Reduced energy consumption and increased energy savings were the driving force behind our new all-electric system,’ said Tom Michalsen, Weber’s marketing director. ‘Many facilities today want to meet sustainability objectives by reducing energy consumption. In addition, newly built plants sometimes don’t include the installation of compressed air.’

As a carton approaches the system, the pad gently applies a label to its front panel, then follows around the carton’s corner and wipes the remaining portion of the label onto its adjacent side. The system handles labels up to 4 inches wide and 12 inches in length, and will print and apply labels to a maximum of 15 cartons per minute. A wide selection of thermal/thermal-transfer print engines is available to produce text, bar codes and graphic images at 203, 300 or 600 dpi.

The Model 5300 All-Electric Corner-Wrap operates with Weber’s print-apply software, which simplifies label formatting, editing and printing. Weber also manufactures a wide variety of blank and custom pressure-sensitive label materials.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.