Netherlands manufacturer installs Perfect Proofer

Gift wrap and accessories manufacturer Hoomark, based in Hoogeveen, Netherlands, is expecting to reduce its set-up time and ensure flexo color quality consistency by investing in a table-top wet proofing system from Print Proof Solutions. The Perfect Proofer enables lab technicians to pre-flight ink formulations under actual conditions of the flexo press without the need for fingerprinting.

Hoomark produces a wide range of customized merchandise including wrap, ribbons, bows, cards, bags, labels and packaging for global companies such as Disney, Warner Bros, Barbapapa and Sanrio (Hello Kitty). Its unique designs feature on various types of paper and film materials such as holograms and metallic substrates, using water-based inks. Printing on to a variety of complex substrates leads to lengthy set-up times and material waste because each substrate type requires its unique ink formulation.

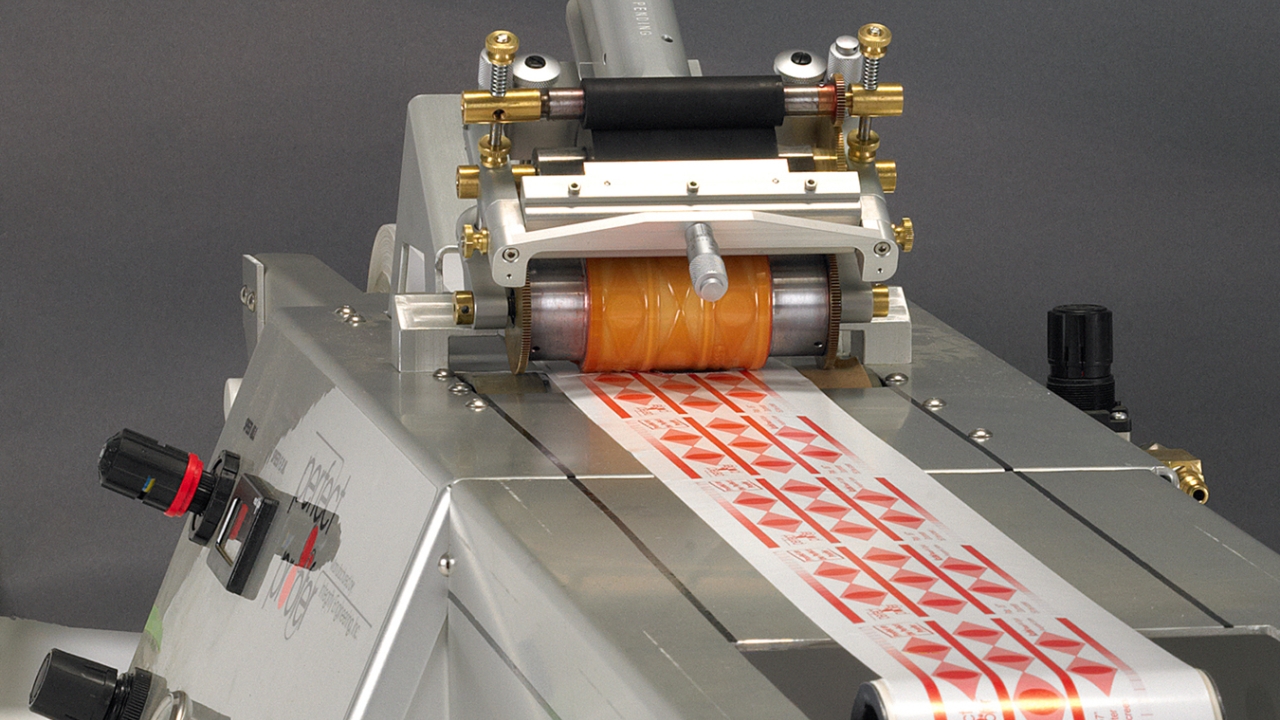

The Perfect Proofer’s exact simulation of press conditions ensures color quality is achieved in any situation. The unit features a miniature printing head, a 1in or 2in anilox roll, and impression roller, which is gear-driven to handle any paper or film substrate, including unsupported types. Impression pressure and nip distances are adjustable by increments of microns. As a result, the proofer is capable of offering full predictability of the target result, to within a fraction of ΔE, at the desired dot-gain, reportedly saving up to 15 minutes’ makeready time per job.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.