Xeikon expands to cartons and flexo CTP

Digital label press pioneer Xeikon has expanded its portfolio for drupa with the launch of a dedicated carton line and new flexo CTP technology. Barry Hunt reports

Xeikon features some notable developments at drupa, including a dedicated printing and finishing system for producing folding cartons, and the unveiling of the ThermoFlexX series of platesetters for flexo and letterpress using the Prinergy Workflow acquired from Kodak. The company will also give a glimpse of Quantum, a future hybrid digital imaging technology.

The company promotes three application-specific suites for the label and packaging markets: the Self-adhesive Labels Suite, the Heat Transfer Labels Suite and the new Folding Carton Suite. Each has the established Xeikon 3000 Series of digital label presses at its core, integrated with application-specific toners, workflow software, substrate and equipment components. The presses can print up to 350gsm paperboard (550 micron/21.65mil), with a web width ranging from 200mm (7.8 ins) to 516mm (20.3 ins).

Roll-to-sheet carton production

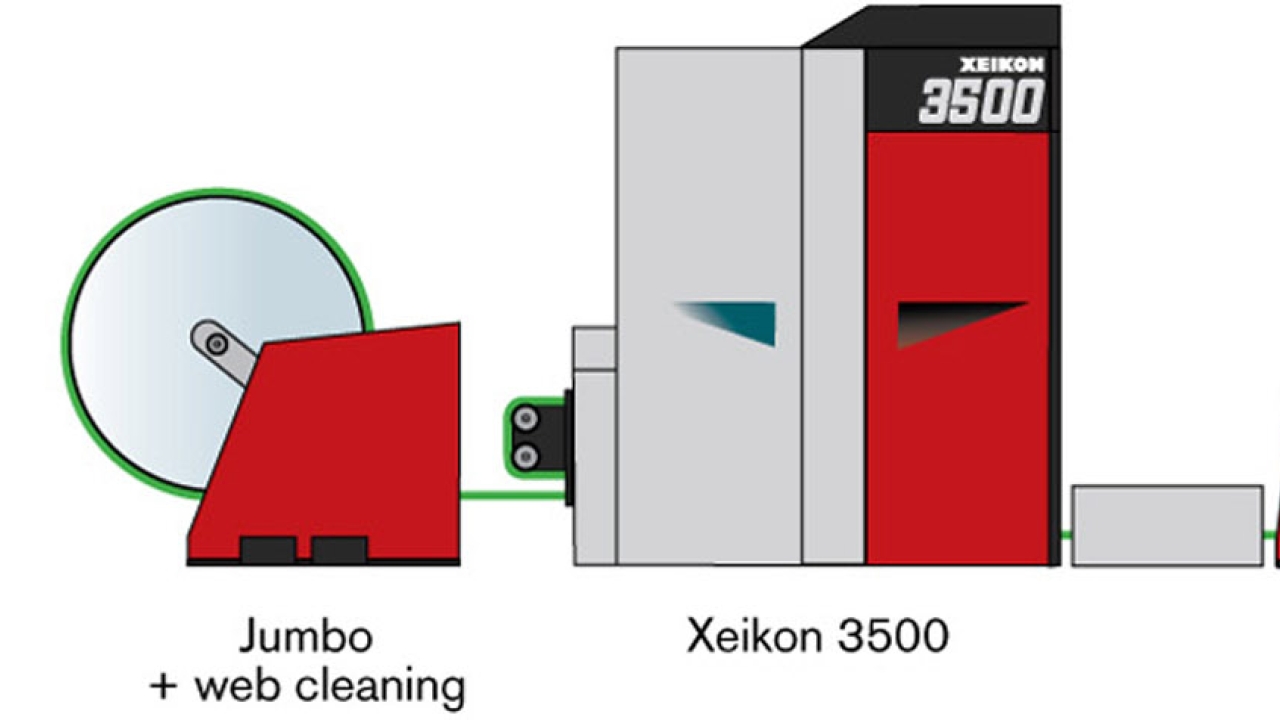

Two Xeikon 3300s will produce self-adhesive labels at the show, whereas a Xeikon 3500 will demonstrate carton production. Its configuration comprises a jumbo unwinder with a web cleaner to collect excess paper dust. A web finishing module (WFM) placed after the print engine reconditions the paperboard. This unit also holds the cutter unit to convert the web into the appropriate sheets defined by the imposition scheme. A stacker collects the printed sheets and separates any type of waste in a separate tray. Modified consumables for carton printing and an in-line densitometer to help maintain quality standards are included.

As with all Xeikon 3000 Series presses, an X-800 Digital Front End drives the digital production workflow. An Adobe RIP incorporates post imposition software and color managements tools. To maximize substrate usage, carton designs are nested on the sheets using an X-800 plug-in to create imposition schemes.

Xeikon’s Aura Partners, including M-real, Iggesund, Stora Enso, International Paper and Sappi supply the certified carton substrates, none of which require special pretreatment. QA-I toner, a dedicated toner for the label industry, is said to offer significant benefits in terms of image quality, light fastness and food safety. Additionally, the Folding Carton Suite includes a range of other certified consumables providing the best option for varnishing, laminating and other post print processes.

‘Self-adhesive labels are common in a roll-fed environment whereas a carton is a single piece, situated in a sheet-fed environment,’ said Filip Weymans, marketing director for Xeikon's label and packaging segment. ‘The Xeikon press has a distinct advantage in this regard since it can produce sheets of variable length and minimize the amount of material wasted. We have been working in this market for more than 14 years since we first introduced our B2 technology. This has enabled us to gain a wealth of knowledge and experience in folding carton production.’

New ThermoFlexX plate system

Earlier this year, Xeikon acquired FlexoLaser, a manufacturer of computer-to-plate devices for both flexo and letterpress applications. At the same time, it also acquired the rights to the ThermoFlex trademark from Eastman Kodak. Drupa will therefore see the unveiling of ThermoFlexX, a series of platesetters, or digital imagers, for flexo and letterpress platemaking. As part of a global reseller agreement, Xeikon includes Kodak's Prinergy Workflow to automate the prepress processes from file creation to finished product. Functions include imposition, trapping, RIP, screening and final assembly of files.

Based on mature technology and proven digital workflow techniques, ThermoFlexX images digital plates at resolutions of 2,540 or 5,080 dpi. User benefits include a clamping design that allows operators to mount plates directly on to the drum, using either vacuum or by magnetic holding methods. The vacuum sliders take plates of any width without the need to cut plates to fit a dedicated vacuum zone.

A glimpse of the future

Drupa visitors can see a sneak preview of Xeikon's latest technology. Named Quantum, it is said to combine the best of two worlds: electrophotography and inkjet while printing high quality images at high speeds. The new technology platform saw significant development time and capital invested in it before Xeikon acquired the full intellectual property rights. Quantum will form the basis for all Xeikon's future product lines for document printing, currently served by its 8000 Series digital color presses. The toner based and waterless non-VOC technology will allow users to print on untreated substrates that are compatible with the existing paper recycling technologies.

Pictured: The Xeikon Carton line configuration to be demonstrated at drupa

This article was published in L&L issue 2, 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.