Avery Dennison hosts sustainability seminar

With circular economy legislation about to hit the label supply chain, Avery Dennison held a well-timed seminar on how converters should respond

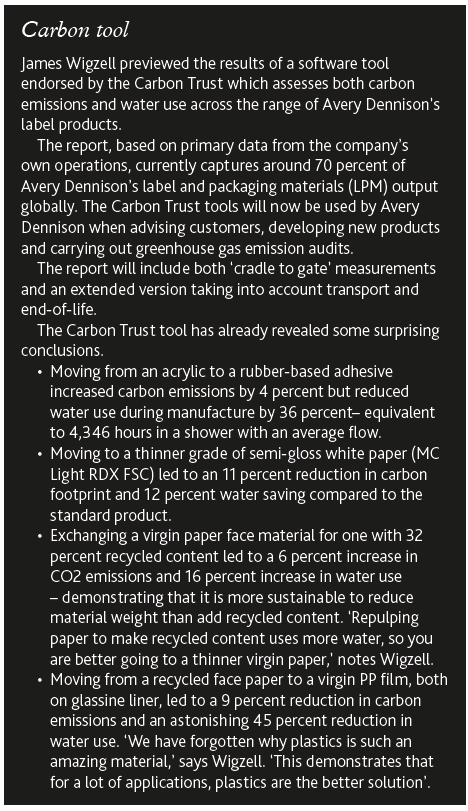

Avery Dennison recently hosted an information-packed seminar on the challenges and opportunities presented by the current debates around sustainability, with UK and EU legislation now forcing the supply chain to address these issues as a matter of urgency. James Wigzell, sustainability lead at Avery Dennison UK and Ireland, kicked proceedings off by looking at consumer perceptions of packaging, particularly the ‘war on plastics’.

‘This has meant that compostable and biodegradable are often at the top of companies’ sustainability lists, or they want recyclable packaging that cuts down on (virgin) plastics,’ says Wigzell.

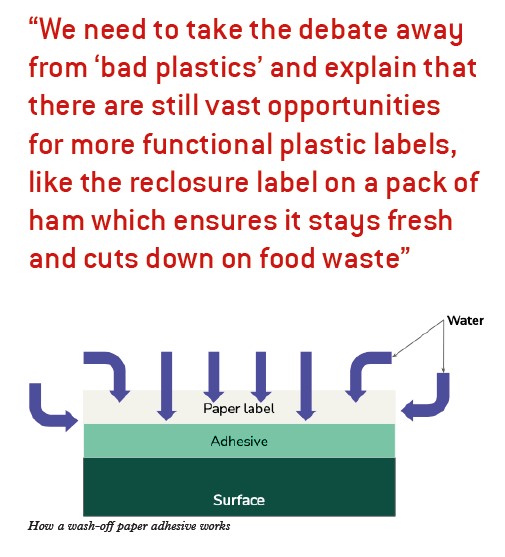

‘But we need to take the debate away from ‘bad plastics’ and explain that there are still vast opportunities for more functional plastic labels, like the reclosure label on a pack of ham which ensures it stays fresh and cuts down on food waste.

Or labels that can make a bottle recyclable where it is not currently. How can we take the consumer on that journey?’

The new legislation will compel brands to properly validate sustainability claims, says Wigzell. ‘Three or four years ago we used to get requests “can we put this on our package” where the claims were unfounded. Now the advertising authority in the UK has cracked down hard. So, data is going to be key going forward, for example, when measuring the carbon footprint of a label or the recyclability of a container.’

Legislation such as deposit schemes and producer responsibility means brands will have to use materials that make the pack or container recoverable, or they will be charged. In extreme cases, the pack could be removed from the market.

‘For example, multi-laminate cartons will have to change. But wet wipes are a good example of where labels have made a plastic pack work. Wet wipe packs are single-use products but are now easy to recycle. Reclosure labels have allowed the elimination of injection-molded lids and a move to flexible packs using less material. The reclosure label can be either PP or PE to match the flexible packaging material, allowing the label and pack to be recycled together. All this happened over two to three years and demonstrates how this has been turned into a labeling opportunity.’

Wigzell pointed out that the cost-of-living crisis does not need to exclude sustainability. Cost reductions can be achieved while obtaining a more sustainable outcome. ‘You can offer thinner products or make containers recyclable, which is a huge benefit for brand owners. Challenges can become opportunities.’

He next addressed the compostable packaging dilemma. ‘The problem is that compostables require industrial and not home composting. But the consumer perception is they can degrade it in their garden or throw it out the car window. In the UK we are not set up for compostables and even where we are, how would the waste processor know if a label is definitely compostable? It is a real challenge and difficult to recommend in the UK. Of course, there is a lot of investment in getting a complete product that is compostable and this situation could be different in other European countries.’

Sustainability certification

To create a level playing field on sustainability, it will be necessary for brands’ claims to be checked by an independent body and then issue a certification that consumers can trust.

Stuart Foster, CEO of industry-wide advocacy body Recoup, noted the urgent requirement to standardize guidance for brands and their supply chain. Already, for example, the UK has started diverging from the EU on food contact regulations.

Foster echoed Wigzell’s earlier comments about biodegradable packaging. ‘Recoup supports biomass as an input but not biodegradable packaging.’ Foster referred to a current court case where Symphony Environmental is challenging the EU’s ban on oxo-degradable technology for single-use plastics. Oxo-degradable accelerates the breakdown of plastics into ever smaller components, but the EU argues that this leaves micro-plastics in the environment.

Foster outlined a partnership with RecyClass, an offshoot of Plastic Recyclers Europe, which chose to pair with Recoup for their UK testing/approvals. The RecyClass coalition has 780 members which takes in the entire packaging supply chain, including processors.

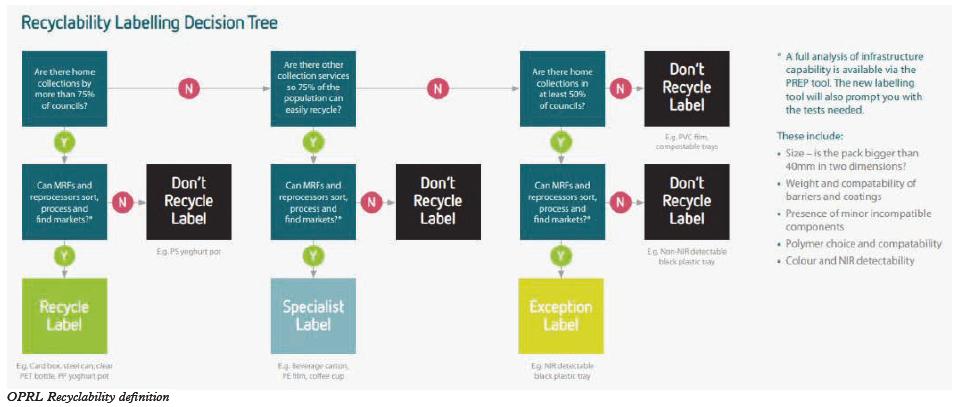

OPRL (On Pack Recycling Label) focuses more on the infrastructure set up in the UK to recycle particular pieces of packaging. Where RecyClass focuses more on individual components - label, cap and flexible package - OPRL focuses on the finished pack.

Margaret Bates, managing director of OPRL, explains the mission to deliver ‘simple and consistent’ messaging around what counts as recyclable and refillable packaging.

To earn a OPRL certification a container or pack must be realistically recyclable. This means, for example, that a container should be collectible by 75 percent of local authorities.

‘All compostable or biodegradable packaging will get the “Not Recyclable” badge until there is a guarantee of appropriate processing facilities,’ says Bates.

Multi-layer pack constructions will find it increasingly difficult to achieve certification, while multi-component packaging could require each component to be labeled separately.

‘This will change the way packaging is designed and will boost UK recycling rates – it will definitely impact on business,’ says Recoup’s Foster.

To achieve a RecyClass ‘Refillable’ certification, packaging will be required to be refilled with the original product a minimum of 10 times. Refill systems must be available to at least 75 percent of the UK population who could potentially have purchased the pack; refilling facilities must be available for a minimum of three years and must be certified as without risk to the consumer.

‘We need these labels because the majority of consumers currently put items into the recycling bin without checking whether they can be recycled,’ says Foster.

Extended Producer Responsibility regulations will require that by 2025 recyclability of all packaging must be assessed, with a scale of fees based on recyclability to be paid by any company which places packaging onto the market or imports it. Data collection provisions require companies to break their packaging into material categories.

The UK nations are already diverging in their collection strategies. For example, Scotland is legislating to place a returnable 20p deposit on single-use containers from 330ml to 3L, now expected to be in place by October 2025.

‘A problem is that we do not know yet how recyclability will be determined,’ says Recoup’s Foster. ‘Many things are not clear, except that it will be a lot more expensive. Producers are either really, really worried about it or do not realize they should be worried about it.’

Building a refill network

Cerise Cooper, business development representative at start-up Again, explained how the company is building a unique mobile infrastructure for refillable packaging.

An Again CleanCell can be set up at any location where used bottles are collected. The self-contained plant includes sorting and de-labeling of containers, closure removal, cleaning, drying, computer vision inspection and robotic palletization. Each CleanCell has a processing capacity of 500,000 units a month and is certified food safe.

Cooper says each CleanCell generates 60 percent less carbon emissions than recycling the same container. ‘We have been working to de-label containers using Avery Dennison’s wash-off labels, so for the brand, we are just like a virgin container supplier.’

Again runs a traceability program alongside CleanCell called Tag, which uses a unique QR code embedded in a permanent label that tracks the number of reuses. It offers live inventory visibility and tracking of CO2 emissions in the circular process.

CleanCells are installed within existing supply chains where they can take advantage of existing bottle return logistics. That may be at grocery retailers, national distribution centers or pub chains.

Early adopters of Again’s CleanCell include Diageo and the Greene King brewery company.

‘We are also working with Smol, an liquids. We clean bottles returned by their customers, clean them and send them to Smol to refill and send back to the consumer,’ explains Cooper.

Another closed-loop partnership is with doorstep delivery start-up Milk and More. Milk and More supplies milk and a wide range of other products direct to consumers. When customers return their bottles to Milk and More fulfilment centers, each brand’s bottles are separated using a tracking QR code, cleaned and sent back. This project is currently being scaled up and expected to be up and running by the end of the year.

Experience to date shows that a bottle needs to make at least seven round trips to make the biggest carbon emission gains.

Challenges

Cooper says the biggest challenge CleanCell faces is washing off label residues. Again is working in partnership with Avery Dennison and its converter partners to validate wash-off labels it can recommend to its brand partners.

A big issue is that CleanCell operates at relatively low temperatures and uses an alkaline rather than the more common caustic soda wash.

Three Avery Dennison wash-off adhesives have been trialed to date. Both WX6030 and WW2031 work well, while WW4031 does not wash off at the lower temperatures which the CleanCell soak tank is set to.

Again is testing a range of bottle types with Glass Technology Services in Sheffield, England to qualify them for CleanCell. Variations in bottle shape and size, print coverage, varnish and coating on the label can all affect how the label performs in the CleanCell environment.

‘We also need a huge amount of information from a brand regarding their filling line, temperatures, storage etc to confidently recommend a wash-off label,’ says Cooper.

Cooper says CleanCell makes reuse simple, affordable and scalable for any brand. ‘It has a far lower environmental impact than recycling. We compete with the cost of single-use packaging at around GBP 12p (USD 15C/Euro 14C) per unit; there is zero upfront capital investment since brands can access our network as a service; and we have a team of packaging engineers helping brands ensure they safely reuse packaging.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.