An introduction to label printing and converting

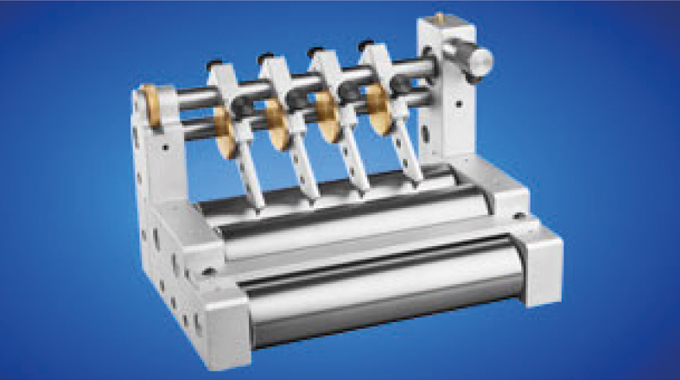

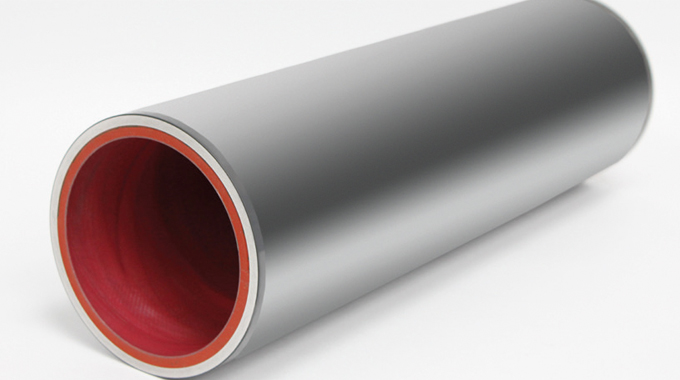

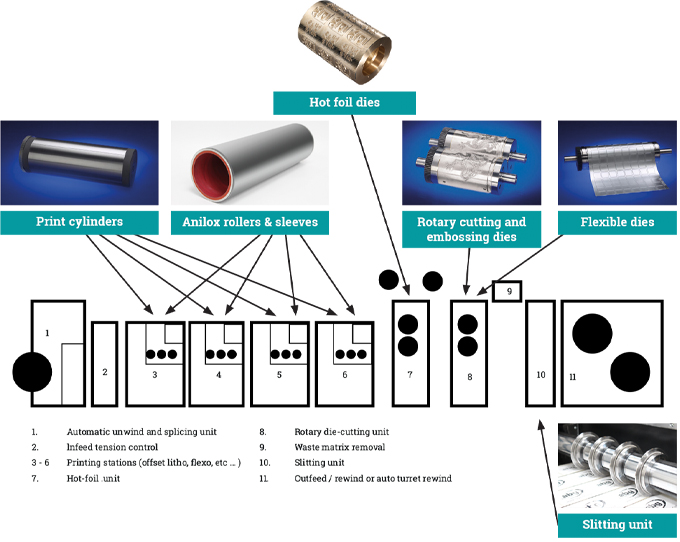

The production of pressure-sensitive labels involves a quite complex process of printing with up to 10 or more printing units, sometimes using two or more different printing processes. Ancillary operations typically follow as needed to die-cut the labels to shape, remove the waste material, trim the edges of the web and slit it into single roll widths – or sometimes into single sheets – prior to a final inspection, re-winding and then packing before shipping to the customer.

Depending on the specific label application, the types of labels to be produced and their added-value requirements or complexity, it may also be necessary to undertake a variety of other types of finishing or embellishing operations, such as varnishing, embossing, hot or cold foiling, perforating, scoring, sheeting or hole punching.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.