Bobst announces new products and strategic partnerships at drupa 2024

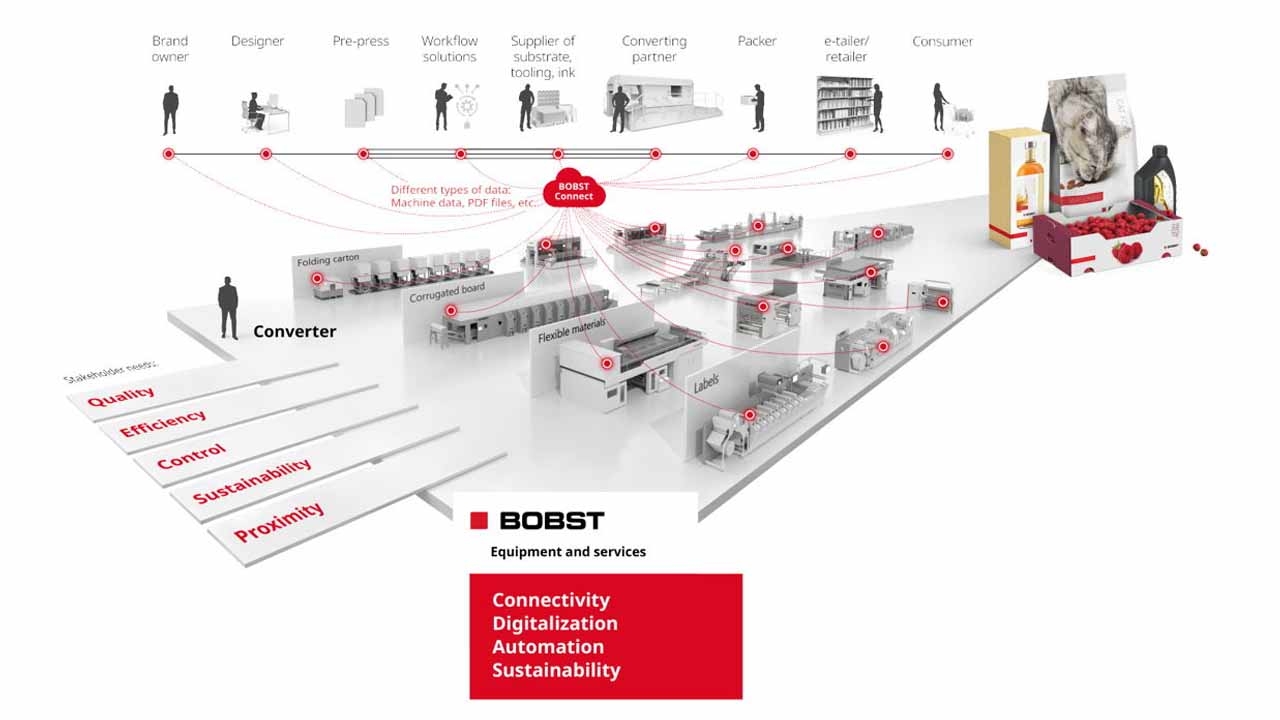

Manufacturer launches new products for connected production line, enabling seamless end-to-end workflows.

Bobst has announced its latest products and strategic partnerships at drupa 2024 to help converters achieve connected production line. enabling seamless end-to-end workflows.

‘We are fulfilling our industry vision “to shape the future of the packaging world” based on the pillars of connectivity, digitalization, automation, and sustainability,’ said Jean-Pascal Bobst, CEO, Bobst Group. ‘Our solutions empower printers and converters to embrace digitalization while advancing towards a more sustainable future. We are proud to engage with industry leaders, forge new partnerships, and chart a course towards continued innovation and progress.’

In the packaging sector, Bobst is taking connectivity and digitalization to the next level by enabling a closed-loop workflow ecosystem from pdf to twin pdf said to boost productivity, ease of use and contribute to sustainability.

New features of Bobst Connect cloud-based digital platform include a major update to equipment monitoring, providing more detailed data insights, while performance management provides insights on equipment, shift and job performance and energy consumption, optimizing sustainability and cost.

For labels, the new cloud based Bobst’s Digital Front End (DFE) 3.0, will be showcased for the first time to the public and be commercially available later in the year.

It enables access to real-time data, resources and workflow templates anywhere, at any time. Color management can be managed centrally and shared in the cloud, and its web-based interface supports multiple users across multiple sites.

Bobst has also launched a cloud-based certified substrate library in Bobst Connect, which allows converters to access up to date Bobst certified material lists to fast-track substrate calibration.

Bobst has updated Accucheck for its narrow-mid-web solutions, featuring major productivity improvements and new automation features.

Inspection improvements to Accucheck include automatic quality inspection setup for every job, and job queue synchronization ensuring zero setup time. This eliminates the bottleneck for quality control setup, meaning customers can inspect every single job without any extra time or effort, according to Bobst.

Calibration improvements include a new color uniformity feature; the automated process for all colors now takes a fraction of the previous time, claimed to save several hours. Meanwhile, the advanced color-to-color registration now performs complete calibration in 15 minutes, while another new feature enhances automatic nozzle compensation to include deviated nozzles in addition to missing nozzles.

Thalia ink is a new generation of UV digital inks designed to meet the highest standards in ink compliance. They are TPO free, and compliant with major regulations including Reach and EuPIA GMP. Bobst Thalia inks are without any CMRs (carcinogens, mutagens or reproductive toxins) and are compliant with the latest Swiss Ordinance announced in February 2024. The inks are compliant with the current and upcoming regulations. In addition, the new ink set has better resistance performance and improved color gamut.

In flexible packaging, Bobst’s extended color gamut (oneECG) technology used for gravure printing has been fully validated by Pantone. This means that the Bobst Master RS 6003 gravure printing solution is officially able to reproduce the Pantone library within a required level of accuracy.

Bobst is continuing and expanding Bobst Connect’s collaboration with Microsoft to reinforce its data and cloud-based software capabilities. In an increasingly AI-driven environment, this collaboration provides cloud-based infrastructure, expertise, and data security.

Bobst recently entered into a strategic partnership with Packitoo, a French company developing digital products in the packaging industry. Packitoo HIPE is a web-based sales tool, which automates quotations, manages packaging projects, and supports web-to-pack e-shops for printers and converters. The partnership aligns with Bobst's strategy to digitalize and connect the entire packaging value chain, from brand owners to converters and equipment suppliers.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.