Siegwerk launches Cirkit Clearprime UV E02 primer in Europe

Manufacturer conducts first field test of the new primer with European converter Masterpress.

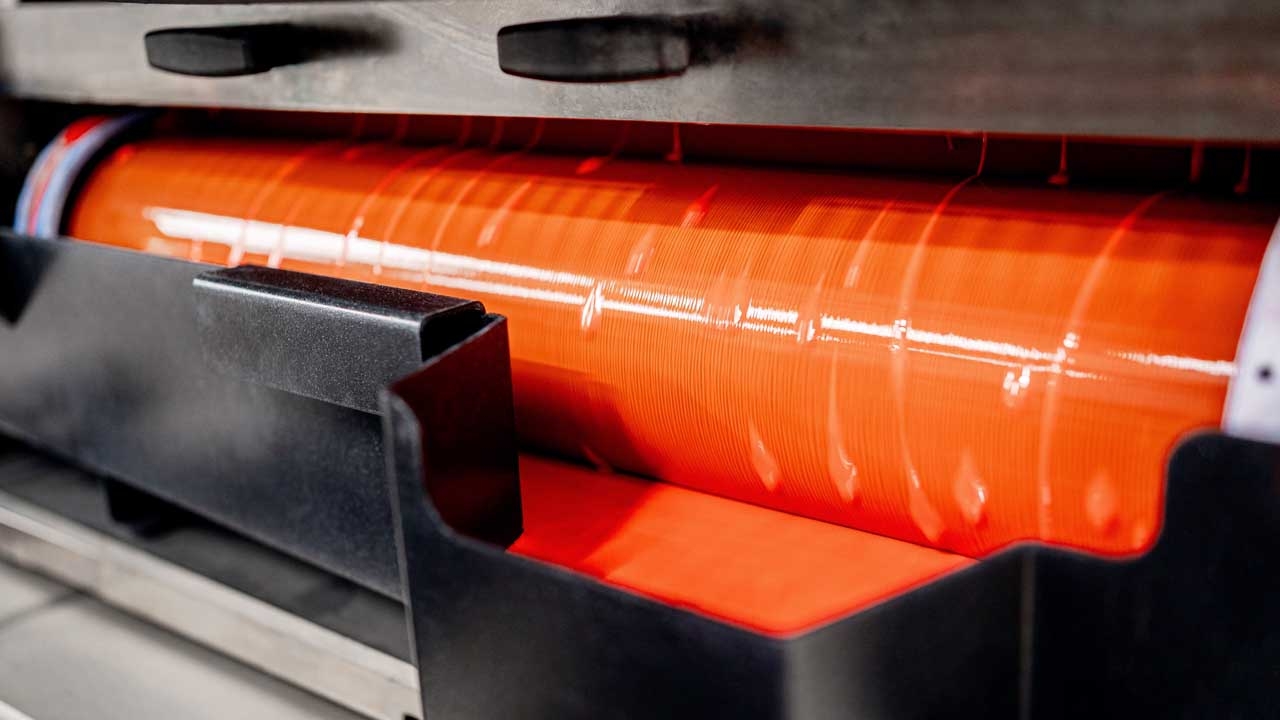

Siegwerk has launched its first full UV flexo deinking system Cirkit Clearprime UV E02 for the European market.

The new primer technology for non-food packaging applications offers a validated solution for safe and economic deinking of UV-printed self-adhesive labels (PSL). It improves the recyclability of labeled plastic packaging and enables the recovery of high-quality recyclates that are suitable for reuse in non-food packaging applications.

Although UV inks offer some advantageous properties for printing labels, they also pose a challenge for the subsequent recycling.

Marc Larvor, head of technology narrow EMEA at Siegwerk, said: 'Depending on the substrate, UV inks are often very difficult to remove and can therefore lead to contaminations of recyclates, which significantly limits their further reuse. As a result, it is not surprising that UV-printed packaging has so far been considered as problematic in terms of a circular economy.’

With Cirkit Clearprime UV E02, Siegwerk now offers a primer that specifically addresses this challenge. By enabling easy and safe deinking of UV-printed self-adhesive labels, it eliminates the need for prior label removal if the used plastics are compatible.

‘Such combined mechanical recycling of labels and plastic packaging can not only help to increase recycling rates, but also to save time and costs,’ added Larvor. ‘Thereby, our new UV flexo deinking primer actively contributes to realize high-quality recyclates for circular waste streams.’

In a first field test with Masterpress, one of Europe’s leading suppliers of high-quality labels and printed decorative packaging, Siegwerk’s new deinking primer has proven its effectiveness in all aspects. Masterpress’ research and development (R&D) experts used uncoated transparent or white pressure sensitive labels (PSL) made of PE85 and applied Siegwerk's Cirkit Clearprime UV E02 followed by bleeding resistant UV flexo inks and an UV flexo OPV.

First, the primer created a quality adhesion between substrate and inks and later enabled full ink and varnish removal of the printed polyethylene (PE) film at standard deinking conditions based on the QT 507 washing protocol of the European PET Bottle Platform (EPBP). The primer layer also dissolved residue-free in the hot washing process and thus generating high-quality transparent or white recyclates, while the used non-bleeding ink formulations ensured a clean and reusable washing solution.

In-house laboratory tests at Masterpress and Siegwerk have shown high-quality recyclate results.

Katarzyna Wasilewska, research and development manager at Masterpress, said: ‘Consistently investing in its R&D laboratory, Masterpress brings state-of-the-art capabilities to test and trial new inks or materials before they enter the market. We are dedicated to advancing innovation within the shrink sleeve and self-adhesive label industry and are well positioned to help accelerate the commercialization of new, sustainable, recyclable products and materials on the market. Our tests confirmed an impressive recyclability of the UV-printed PE labels. Compared to other labels with no deinking technology, we could observe that contaminations of plastic recyclates due to discoloration could be massively reduced by using Siegwerk's UV Deinking Primer.’

Cirkit Clearprime UV E02 works with the company’s Sicura flexo series such as the non-low migration Sicura Flex 39-8 or the dual-curing series Sicura Flex Dual Cure. In addition, the new primer is compliant with different film materials and allows an inline printing of deinkable materials in a 100 percent UV-flexo press setup keeping the complexity for users as low as possible.

‘With only three minutes, the new UV flexo primer even offers a deinking speed as fast as a water-based deinking primer making it to a great alternative for converters who are using a pure UV flexo press and are not able to process a water-based primer,’ added Wasilewska.

Currently, the company’s portfolio of circular coatings already covers several water-based and solvent-based technologies for different applications, substrates, coating processes and performances. This includes barrier coatings against liquids, oil and grease, water vapor, oxygen, and UV light through heat seal and protection coatings to delamination and deinking primers.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.