All4Labels Hamburg automates platemaking

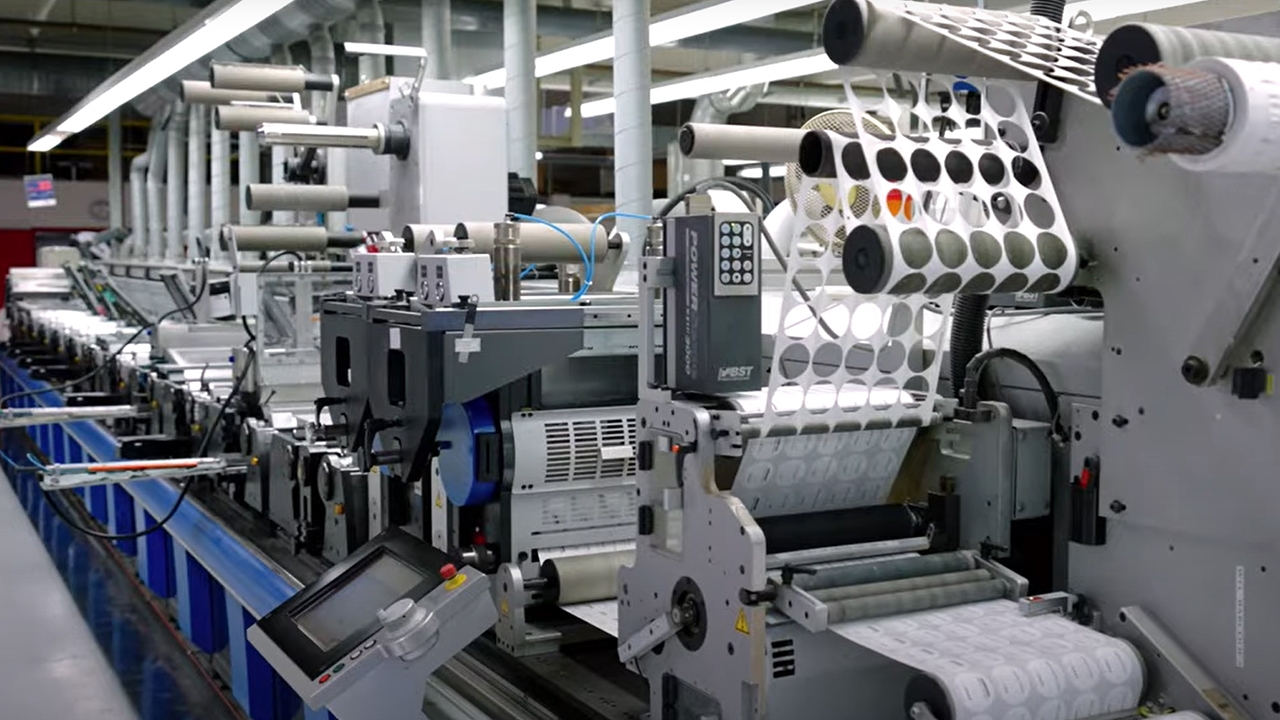

German site installs CrystalCleanConnect, an automated platemaking system developed by Asahi Photoproducts, Esko and Kongsberg.

All4Labels’ site near Hamburg, Germany, has seen a significant boost in productivity since installing the CrystalCleanConnect automated platemaking system developed by Asahi Photoproducts, Esko and Kongsberg.

Half a year ago, the German label converter installed the system to replace a manual platemaking process, resulting in ‘errors and scheduling problems,’ according to Mirco Wilke, head of pre-press, flexo printing, at All4Labels Hamburg.

‘Hamburg is one of the main printing facilities in the All4Labels Group,’ said Wilke. ‘At the time of the installation, the focus of the pre-press department was on flexibility in production and high output through all our different presses. But it was a very manual process which had some drawbacks and restricted future development.

‘We had no automation or connectivity to our workflow systems. It was hard work for the operators to handle all the different machines. It was stressful for them and could result in errors or scheduling problems. CrystalCleanConnect had answers to all these problems. We could connect to our workflow systems, automate the whole process, and minimize the operator’s hands-on work.’

The system is the result of two years of joint development between flexo photopolymer plate pioneer Asahi Photoproducts, integrated software and hardware specialist Esko, and Kongsberg Precision Cutting Systems, and was prompted by All4Labels Hamburg’s desire to produce plates during a night shift with minimal operator input and consistent quality.

CrystalCleanConnect automates the platemaking process by reducing the number of steps from 12 to one. It can deliver up to a 90 percent reduction in dedicated operator time, an average 25 percent increase in press OEE, and a 20 percent reduction in ink usage.

‘A standard platemaking machine with two operators can normally produce 24 plates in an eight-hour shift,’ says Dieter Niederstadt, technical marketing manager at Asahi Photoproducts. ‘With CrystalCleanConnect, the total operator time of just one person is one hour. Everything is automated, from the laser imaging to the plate cutting, which wasn’t possible in the past. Additionally, the machine uses water-washable plates – which are certified as carbon neutral by the Carbon Trust – to allow for solvent-free, more environmentally sustainable production.

‘Standardization is another key benefit. With different operators working different shifts, inevitably, you will have different plate qualities. But if you have an automated process, then everything is standardized – every day, every month, every year – which is a huge benefit to the printer.’

Pascal Thomas, director of Esko’s flexo business, added: ‘CrystalCleanConnect is particularly suited to larger operations running multiple shifts. It is a system that works well in a 24-hour operation; for example, it can be run during a night shift by a press operator who makes a few plates and then goes back to printing. Because it’s fully automatic, you don’t need much training to operate it. It’s plug and play.’

According to Wilke, flexibility and quality are the key demands from All4Labels Hamburg’s customers, which are requirements that CrystalCleanConnect helps the company deliver.

‘As print runs become shorter, we must always be flexible in our print production and time to market,’ said Wilke. ‘Quality is also crucial. We have to be faster; we have to be sustainable; we have to automate as much as possible and connect with our customers in all kinds of processes and workflows.

‘When we invest in new technology, we always look at the connectivity to our automation systems and workflows, and at the productivity of the machine. And of course, at the price – it must be a sustainable product for our customers and for us.’

All4Labels Hamburg was producing plates on the new system after just a couple of weeks of training.

‘The process was straightforward,’ commented Wilke. ‘The fact that CrystalCleanConnect allows us to put our print files directly from prepress into a whole connected system, reduce waste, reduce operator input, and automate the whole platemaking process, are huge advantages.’

A further development from Asahi, which can be linked to CrystalCleanConnect, will be unveiled at this year’s edition of drupa. The AWP-Loop system is a closed-loop waste-water recycling technology based on Asahi Kasei microza technology, which can recover and reuse 80 percent of the water used in the plate washing process.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.