DLS expands RFID label offering with Mark Andy servo die-cutter

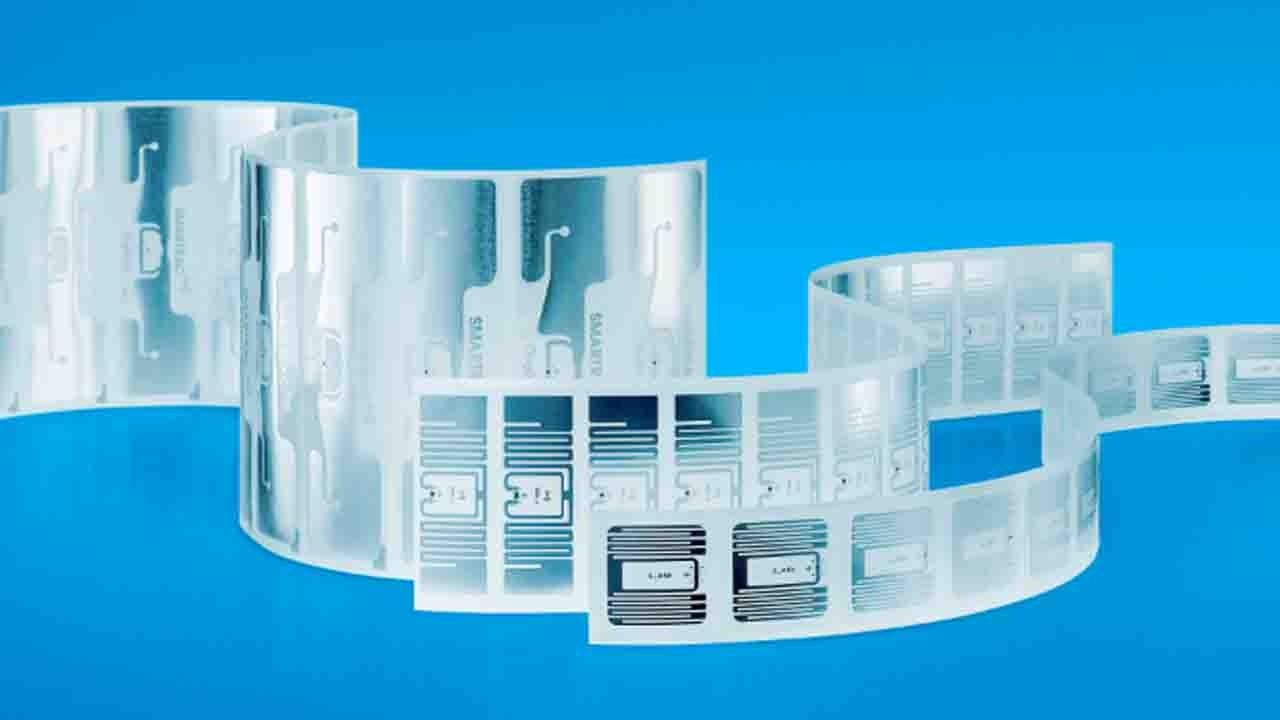

US-based converter invests in a new servo die-cutter station to accommodate the increasing demand for RFID technology.

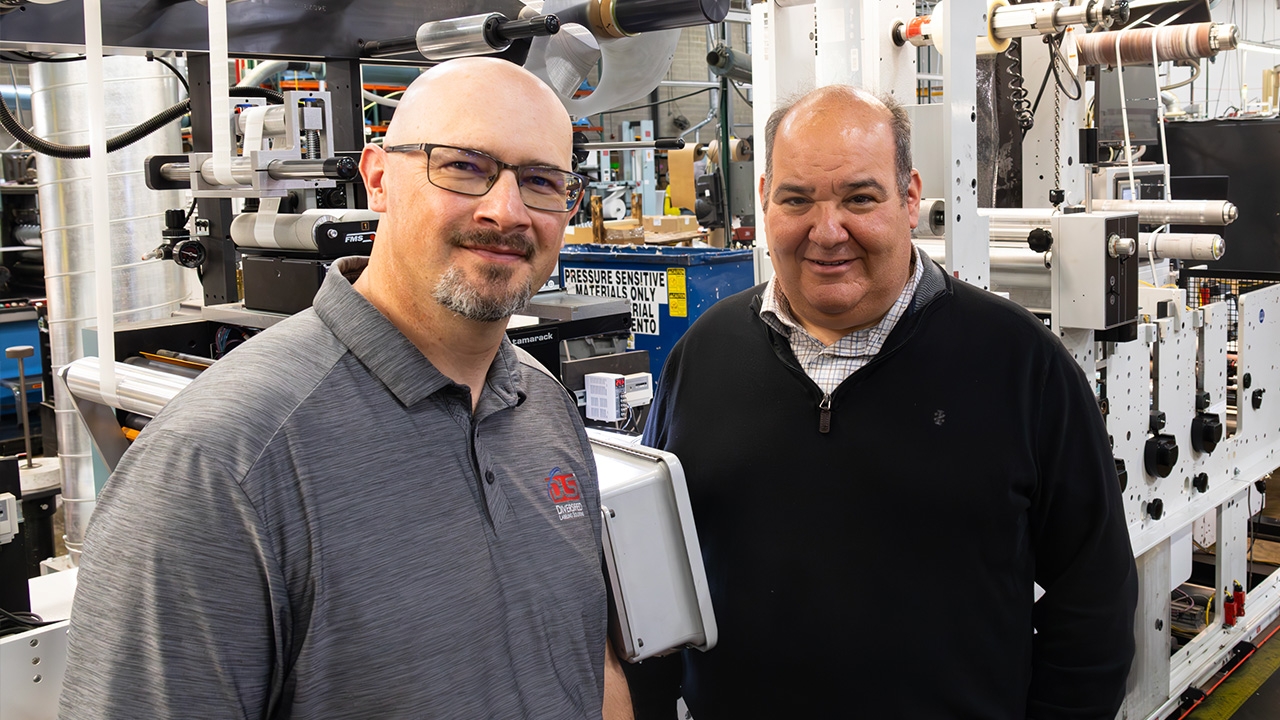

L-R: Ryan Zins, RFID manager at DLS, and Mike Kaufman, vice president of manufacturing at DLS, are in front of the new Mark Andy servo die-cutter.

US-based Diversified Labeling Solutions (DLS), a national converter of pressure-sensitive labels, has invested in a Mark Andy servo die-cutter station to expand its RFID production capabilities.

The new servo die cutter station gives DLS the advantage of inserting RFID inlays into preprinted material from any press, including the HP Indigo, as well as preprinted webs from other print companies. This allows for expanded prime RFID label production.

Since the demand for both prime labels and RFID technology continues to grow in the retail and logistics industries, this new RFID expansion will help DLS maximize opportunities for its distributors.

‘Diversified Labeling Solutions has been at the forefront of servicing the RFID label demand,’ said DLS vice president of manufacturing, Mike Kaufman. ‘This new servo die-cutting station is instrumental in creating more RFID solutions for prime labels in the retail space.’

‘Having the expanded capability to provide prime RFID labels allows us to offer customers a strategy for complying with the retail mandates that don’t sacrifice branding. We can also now offer fellow print companies the ability to insert RFID inlays into their customers’ printed labels and packaging,’ added Ryan Zins, DLS product manager for RFID Labels.

With the recent mandates creating more urgency for RFID implementation, the servo die-cutter is a welcome addition to DLS’ existing RFID products and services. In addition to the new prime RFID label offering, DLS provides stock and custom RFID labels, Walmart RFID labels, service bureau printing and encoding, TSC Printronix RFID printers, and customer support, such as RFID label training.

‘We're integrating RFID tech into prime labels for a more polished and simplified solution for inventory tracking and fewer labels on the products,’ said James Cirigliano, vice president of marketing at DLS. ‘It's all about reducing the overall cost of product labeling and helping our customers differentiate themselves from the competition.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.