Miller Graphics Group expands Esko platemaking products

Focus on sustainability, quality and productivity leads to additional investment.

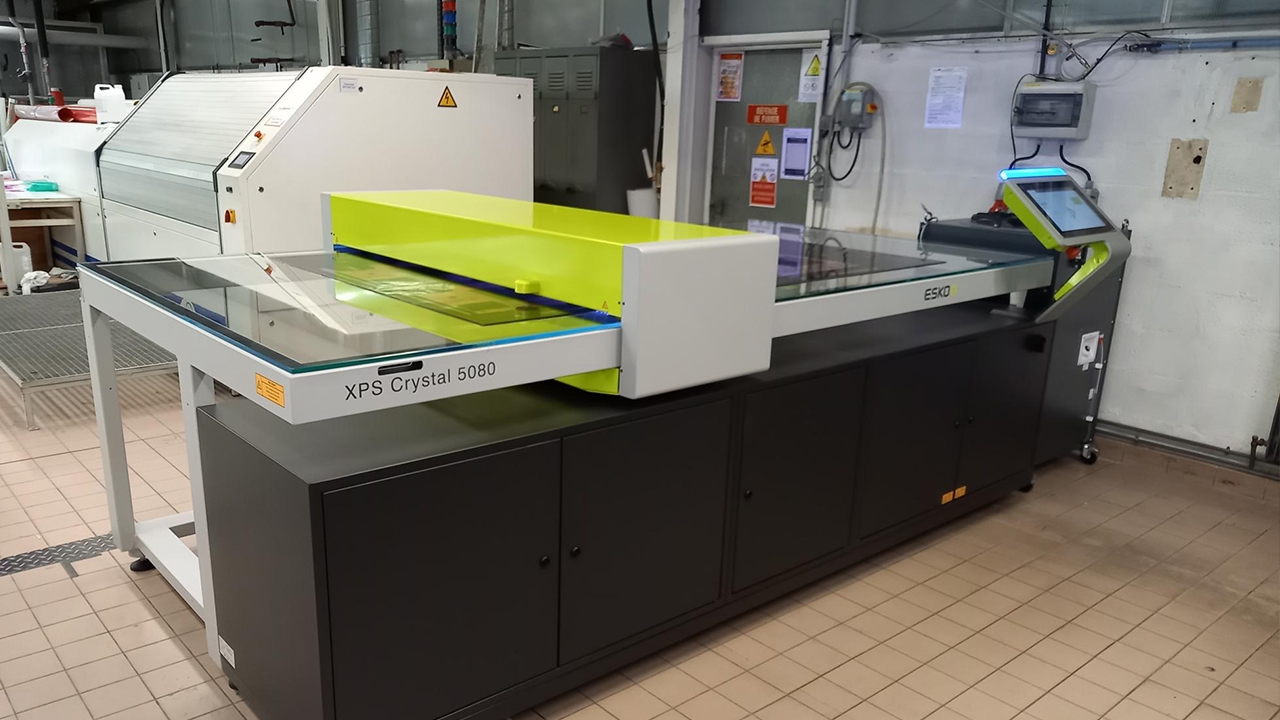

Miller Graphics Group has increased its fleet of Esko platemaking software and hardware with the addition of a new fully automated CDI Crystal 5080 XPS at its Roeselare, Belgium facility and an award-winning XPS Crystal at its site in Limoges, France. The company has also introduced the Esko Flexo Engine automation technology to boost efficiency, productivity and performance at its other sites in Belgium, France, Sweden and Poland.

Philippe Bataillie, president of Miller Graphics Group, said this latest investment in the fully automated Esko Crystal line of plate imaging and exposure hardware and software followed on from an initial investment in 2022.

‘At Miller Graphics we are committed to achieving and maintaining the highest quality flexo results, while at the same time making our production sites more sustainable through reducing the usage of mercury and solvent,’ said Bataillie. ‘Since we first installed the Esko CDI Crystal 5080 XPS with plate handler and automation at two sites in Sweden and France, we have benefited from consistently high-quality results and a very stable production environment. Importantly, across the last year and a half we have also recorded significant benefits in terms of using less resources through the automation and standardized production, and ultimately a more sustainable plate production process using LED compared to mercury lamps.

‘In addition, the implementation of the Esko Flexo Engine solution will also reduce our solvent consumption and contribute to achieving our sustainability objectives.’

The XPS Crystal plate exposure unit uses a front and back UV LED array instead of the mercury tubes used in traditional main exposure bank lights. This digital UV LED exposure not only significantly improves the quality and consistency of flexo plates, but the UV power required for perfect curing of a plate is provided uniformly through preset parameters by a single click per plate type and plate thickness.

The XPS Crystal recently achieved both Certified Energy Savings and Dematerialization certifications from GreenCircle - an internationally recognized third-party certification entity that independently verifies the validity of sustainability claims.

Pascal Thomas, director of flexo business at Esko, commented: ‘In contrast to bank exposure frames, which consume a relatively large amount of energy from preheating, through the exposure time and idle time during the entire working shift, the UV LEDs of the XPS Crystal are only activated for the back UV exposure and the main exposure of the flexo plate. The energy consumption in the idle state is almost zero and clearly helps Miller Graphics meet its own sustainability objectives.'

In 2022, Miller Graphics was hailed for being the first company to fully automate the plate making process in the French and Swedish markets.

With the addition of the new Esko Crystal line at Miller Roeselare in Belgium and Miller Limoges in France, it has further expanded its fleet of software and hardware that gives operators complete control over the quality and performance of its plates and print consistency.

‘The combination of Crystal screening technology and Esko automation delivers improved consistency and ensures the platemaking process is much less complex, with significantly fewer steps and eliminating wasteful errors,’ added Thomas. ‘We are thrilled to continue our relationship with Miller Graphics and to enable them to further expand and automate their platemaking capabilities throughout Europe.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.