Drupa 2024 review

Drupa is not usually the first port of call for the label community but is always an opportunity to look at wider trends in the package print converting sector.

Although most major launches for labels and mid-web packaging converters were made at Labelexpo Europe last year, there was still much interest in label and packaging technology at drupa 2024.

The event in Düsseldorf, Germany, drew 1,643 exhibitors from 52 nations over 11 days and 19 halls.

Water-based inkjet

Perhaps the key theme was water-based inkjet, with prototype machines from both Canon and Epson on display along with the recently launched FujiFilm FP790.

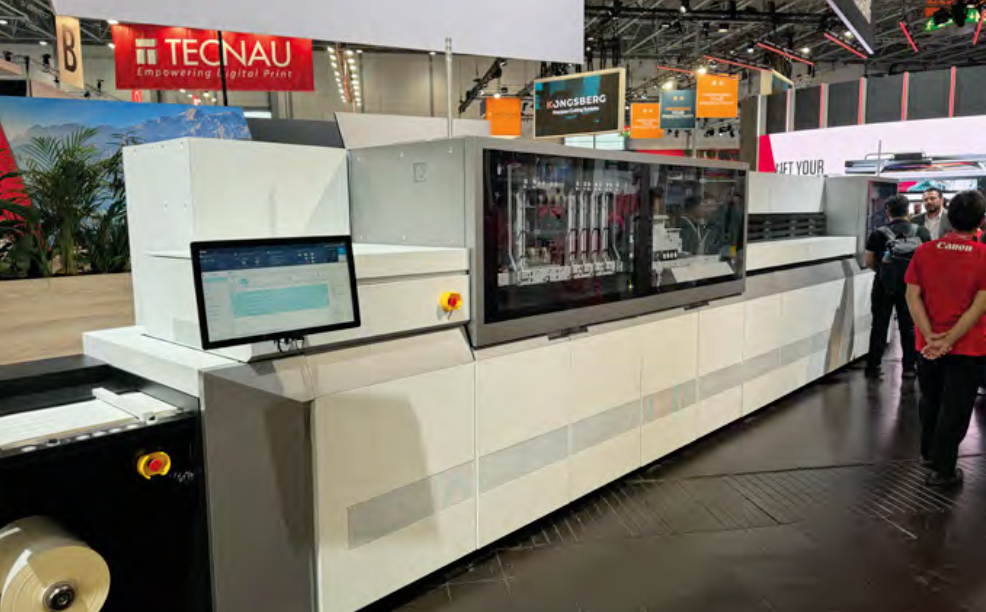

The Canon LabelStream LS2000 prints at 40m/min CMYK + white and features a new 2,400 x 1,200 DPI printhead with ink recirculation to help eliminate nozzle clogging and extend printhead life.

Food-safe polymer water-based inks were developed by Canon specifically for these printheads. Canon says the inks contain highly saturated pigments which produce a wide color gamut. Because the inks form a very thin layer on the substrate, reduced scattering of light results in high-quality color reproduction, according to the company.

The press features a unique design with two priming stations; at one end with CMYK, and the other with white. The white is printed first, and the inks are dried on an extended web path inside the press before application of CMYK inks, followed by further drying back through the press.

Printhead maintenance and quality control are automated, as are color measurement and adjustment.

Qualified substrates for the LabelStream LS2000 include coated, synthetic and textured papers and even some heat-sensitive films.

The press is based on the same core technology as Canon’s varioPrint iX1700 sheetfed inkjet, allowing the company to transfer proven technology from the commercial sector.

The LabelStream LS2000 will be commercially available in 2025.

Also on the Canon stand were modules from an Edale FL5 in-line folding carton converting line, capable of adding cold foil, cast+cure or varnish before moving to the FDC600 flatbed die-cutter for cut/crease, braille/embossing and waste stripping.

Epson demonstrated a concept 6-color aqueous inkjet press designed as the successor generation to the company’s existing and highly successful L-4000 series aqueous presses.

The L-4000-series presses use an x- y frame to build an image before the web indexes forward, limiting speeds to around 8.2m/min. The Concept press currently operates at 13m/min. It still prints one frame at a time, but the page-wide array makes a single pass over the length of the frame before the web moves on.

“Epson demonstrated a concept 6-color aqueous inkjet press designed as the successor generation to the company’s existing and highly successful L-4000 series aqueous presses”

Nozzle verification technology has also improved, so nozzles are continuously monitored in real-time and nozzle compensation happens in the background. The press prints at 1,200 x 1,200 DPI resolution.

The Concept press uses a new version of Epson’s established AQ water-based resin ink technology. An optimizer liquid is jetted onto the material just before the colors to better control dot placement.

Screen, meanwhile, demonstrated its Truepress PAC 520P inkjet press using water-based food-compliant inks to print on paper-based flexible packaging.

The company also displayed the inkjet imaging unit from the Truepress PAC 830F water-based inkjet press for filmic flexible packaging. Also on the Screen stand was a Truepress Label 350UV SAI S UV inkjet press with the newly developed digital primer unit for label printing.

FujiFilm demonstrated its Jet Press FP790 water-based inkjet press for flexible packaging and filmic labels, printing at 50m/min at 1,200 x 1,200 DPI. As noted in Labels & Labeling, the fi st FP790 was installed by Eco Flexibles in the UK, and at drupa the company confirmed the purchase of a second machine.

Landa is still not in a position to demonstrate a web version of its nanographic press technology or to say when the press might be commercially available, limiting itself to print samples from the development W11 press.

On the consumables side, DuPont was promoting its Artistri range of water-based inkjet printing inks and dispersions for commercial and packaging applications, claiming high durability and color fastness. Toyo Inks previewed its next-generation low-energy drying water-based ink technology.

UV and toner

Durst used drupa 2024 as the launchpad for its new KJet hybrid press developed in cooperation with Omet. This is both companies’ second joint venture after the XJet.

Combining the cylinder-based dual-servo flexo technology from Omet, with the Durst RSCi digital printing engine, the KJet has been developed with an ultra-short web path that minimizes waste and reduces the set-up times highlighting the benefits of digital printing. Durst says the power of its automation and register control ‘redefine the concept of versatility’ as the press can cater to a number of applications from labels to packaging.

Thomas Macina, sales director for labels and flexible packaging at Durst Group, says: ‘The combination of digital with flexo offers an innovative hybrid solution that maximizes productivity and flexibility, enabling printers to select between flexo or digital printing, thereby optimizing efficiency and reducing costs while meeting evolving market demands such as personalization and just-in-time deliveries in a single-pass.’

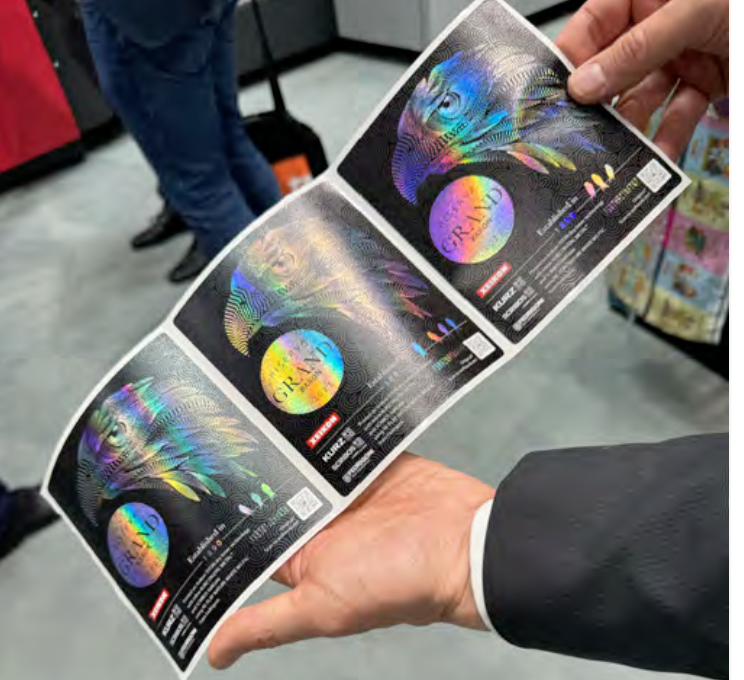

Xeikon demonstrated both a new UV-inkjet press and the digital foiling integration with Kurz first seen at Labelexpo Europe last year. The new 330mm/13in PX3300HD LED-UV inkjet press prints at 70m/min, even when printing high opacity white, at a resolution of 1,200 DPI. The press utilizes

Xeikon’s newly developed px-Cure LED HD ink series, capable of hitting up to 88 percent of Pantone colors within DeltaE 2, rising to 94 percent in DeltaE 3. The new ink set will also be used for the recently introduced PantherCure UV LED series of 600 DPI inkjet presses.

The inkjet heads are Xerox W-Seriesnwith dedicated waveform and screening software developed by Xeikon. The press is prepared for hybrid printing with the option to add Xeikon’s modular in-line LCUs (Label Converting Units) and a large unwinder for uninterrupted production runs.

A key feature of the PX3300HD is an in-line camera system that automatically adjusts registration, stitching and nozzle compensation during setup and running.

Xeikon also unveiled a partnership with Kurz company Scribos to develop interactive brand protection, track and trace, and consumer engagement features based around an inline Kurz Digital Metal embellishment unit. First seen at Labelexpo Europe 2023, the system makes use of the unique curing technology on Xeikon’s Titon dry toner press.

Powered by Xeikon’s X-800 DFE, the application uses Scribos ValiGate technology and Scribos 360 Cloud Platform to image serialized, protected QR codes and metallic variable elements. Not only does each code have a unique ID, but they also contain a finely printed sub-pattern that acts as advanced copy protection.

Also shown was the high-speed ‘Lion’ toner press.

Gallus-Heidelberg made some major announcements concerning the further evolution of the Gallus One digital press system. First is the addition of a 430mm web width to the existing 340mm configuration; second is the addition of orange and violet – jointly developed with Heidelberg - to the CMYK+W print engine. Gallus also introduced its ‘System to Compose’ concept which allows converters to add Labelmaster print and converting modules to the Gallus One.

The Gallus One is built on the Labelmaster platform. The range of available Labelmaster modules includes flexo and screen printing units, cold and hot foiling, embossing and gravure printing as well as die-cutting.

Dario Urbinati, Gallus Group CEO, says this will be a plug-and-play system allowing converters to extend or change the configuration of the press as business needs change.

Interestingly, owners of Labelmaster 340/440 flexo presses will be able to add the Gallus One digital engine to their existing presses - effectively transforming the press into a bespoke Gallus One.

HP Indigo premiered its high-speed V12 narrow web press integrated with ABG automatic non-stop unwind and rewind modules. This greatly increases the productivity of the press, which can print at up to 120m/min in 6-color mode. ABG also demonstrated a Digicon series 3 converting line equipped with a Fast Track high-speed (150m/min) semi-rotary die-cutting module to complement the V12.

HP Indigo also promoted the latest upgrade to its 200K mid-web press which increases the imaging resolution to address markets such as pharma and cosmetics where the ability to print microtext is a requirement.

Automation took center stage, with many exhibitors using the show to focus on AI and smart workflows. HP leadership acknowledged this

‘The HP transformation we announced 20 years ago has fully materialized at drupa 2024 with digital now becoming fully engrained within the print industry,’ says Haim Levit, senior vice president and general manager, HP Industrial Print.

‘The intelligent automation we have demonstrated across our production lines answers our customers’ pain points which are largely driven by labor shortages, energy waste as well as customization and on-demand products.’

“The Canon LabelStream LS2000 prints at 40m/min CMYK + White and features a new 2400 x 1200 DPI printhead with ink recirculation to help eliminate nozzle clogging”

Several other digital label press manufacturers were present including Dilli with its Neo Picasso 600 x 1,200 DPI UV inkjet press and HanGlory with the LabStar 330S hybrid label press.

Seiko Instruments’ printhead division unveiled its 600 DPI Acrobat RCE2560 printhead with recirculation to avoid nozzle clogging. The 2,560 nozzles are arranged across four rows over a printing width of 108.3mm. The RCE2560 offers multiple grey levels with a drop volume range from 9 to 20 pl along with the possibility to accommodate various fluid types, including aqueous, solvent-, oil-, or UV-based inks.

Digital embellishment

Digital embellishment across all types of packaging and commercial print applications was another key theme of this drupa show.

On the labels side, Brotech highlighted its iDM 330 Digital Embellishment System, a multifunctional machine that supports digital white, digital metalization, digital varnish, variable data, barcodes/2D barcodes and braille.

Cartes showed its Gemini GE363VJL tool-free converting and embellishment line including digital printing, foiling and laser die-cutting. The company was heavily promoting the ability of its Jet D-Screen ‘digital screen’ unit to replace Screen print units.

ABG showed off the possibilities of its DigiLase laser die-cutter paired with the dual-head DigiJet print bar, capable of jetting tactile varnishes and other variable spot effects.

Konica Minolta introduced its AlphaJet digital embellishment system, developed with France-based partner MGI Digital Technology. It both inkjet prints and embellishes B1/B2 sheets with varnish and digital foil in a single pass.

Kurz demonstrated its latest DM-Maxliner 3D for haptic digital embellishment, UV spot and relief varnishing. Also unveiled was the DM-Maxliner 2D for digital metallization on a variety of substrates, as well as the MPrint 4C inkjet printing unit for late-stage customization.

For smart label production, LemuGroup showed its LI 220 RFID smart label inserter, equipped with a delam-relam system for accurate insertion of smart inlays.

JetFX showcases its digital embellishments in the HP digital pouch factory, showing embellished pouches with a 30in Solo Flexpack printbar mounted on a Karville Classic Duplex Slitter.

Automation and digitization

Automation and robotization were key trends at drupa. Although these were generally not labels-specific applications, they did point the way forward for all package printing and converting formats.

Berhalter, for example, showed its new B6 Die-Cutter paired with a Beamstack automated packaging system. The robot separates die-cut stacks into the desired number of pieces and automatically packages them into plastic blisters or cardboard boxes.

AV Flexologic showed its RoboCell robotic pre-press technology comprising RoboTape for taping printing sleeves; RoboSleeve for transferring taped sleeves onto the plate mounter and then delivering them to the sleeve rack. The company’s Famm 3.0 system automatically mounts multiple plates.

BST showed its SmartData system to centrally control, optimize and document networkable web monitoring and inspection systems.

EyeC was also focused on AI-assisted inspection, demonstrating a new, AI-based defect classifi cation option for the entire EyeC ProofRunner line.

Enfocus joined the team from Esko, X-Rite and Pantone for an innovation lab including a new AI-assisted decision-making tool for upstream packaging project specifications. This complemented Esko’s unveiling sCloud, a cloud-native platform that includes computing, data sharing and AI functions. All existing Esko applications - from ArtPro+, ArtiosCAD, and Phoenix through to Cape Pack and Automation Engine - will connect to the new platform, giving authorized users 24/7 real-time access to live data and common resources.

“Also on the Screen stand was a Truepress Label 350UV SAI S UV inkjet press with the newly developed digital primer unit for label printing”

Hybrid Software Group showcased the AI-driven automation features of its Packz packaging pre-production software alongside its CloudFlow modular workflow suite. The company’s MyCloudFlow workfl ow integrates CloudFlow into a SaaS workspace fully operated and managed by Hybrid Software.

Although not specifically related to labels, Tecnau showcased strategic collaborations with Canon, Fujifilm, HP, Kodak, Ricoh, Screen, Heidelberg, Horizon, Kompac and Smyth which enabled robot-assisted automation of both print and end-of-line packaging. The company showcased advances in its industrial-grade IoT system Tecnau Connect, which reports and analyzes production statistics.

Sheetfed

Drupa is a good place to catch up on sheetfed wet glue and IML print and finishing technologies.

Blumer Maschinenbau presented its Atlas-1110 Double Stack, which allows two strips to be processed simultaneously. Blumer also presented its AG-4220 counter-pressure die-cutter, a new technology for large-format paper and IML labels. The company was exhibiting together with the Postpress Alliance - an association of leading print finishing companies.

Plockmatic Group showed its ColorCut LC330, a compact automatic label sheet cutter designed for unattended operation.

It includes a 150-sheet auto feeder capable of handling sheet labels up to 330mm wide x 483mm long and is suitable for all common label sizes, delivering up to 800mm/s cutting speed and a maximum pressure of 500g.

The ColorCut Professional series LC700 Pro label cutter is a sheet label cutter for automated high-volume label production. It provides high-speed precision cutting at speeds up to 1.2m/s and up to 760g of pressure.

The flagship model on show, the LCF700 Pro, takes 330mm width rolls with a maximum outer diameter of 350mm and includes a station to apply laminates before cutting. The LCF700 Pro has a waste matrix removal system and includes a five-knife label slitter with an advanced tracking system.

Heidelberg showed off the automation features on its new Speedmaster XL 106 alongside a highly automated end-to-end packaging workflow.

A key trend at the show was the introduction of new digital sheetfed presses, both toner and inkjet-based. Konica Minolta, for example, introduced the AccurioJet 60000, the successor to the established AccurioJet KM-1 and KM-1e, first released in 2016. The AccurioJet 60000 boasts a throughput of 6,000 sheets/hour using HS-UV ink.

Wide web converting

Wide format print and converting systems are commonly used for wraparound and shrink sleeve labels and some long-run PS jobs as well as flexible packaging, and automation along with digital hybrids were the key trends at the show.

Uteco demonstrated its OnyxOmnia hybrid press which combines Uteco’s CI flexo core technology with a SmartJet inkjet module. The press runs at 400m/min flexo only and 300m/min with digital on a maximum print width of 1320mm.

The press is designed as a hybrid system with a similar concept to narrow web hybrid, in that the flexo units are designed to complement inkjet rather than the other way round. Six flexo units allow for spot colors, primers and whites with the last unit being convertible to a roto unit for overprint varnish.

Windmoeller & Hoelscher was promoting a concept technology for hybrid printing developed with Epson which incorporates four flexo stations and seven digital. On the company’s stand was an entry-level AlphaFlex press, printing 8-colors and 400m/min and a maximum print width of 1,270mm.

BW Converting showed flexible packaging samples produced on its Ion hybrid digital press, printing at 400m/min, though this was not on the stand.

Bobst introduced its SmartGravure technology which aim to automate job setup and tuning along with the configurable Expertlam 900 coater and laminator.

Comexi launched its F1 evolution CI press, printing up to 600m/min on a print width up to 1,690mm. The press can be equipped with a robotic arm for sleeve and anilox changes, as well as other automation systems from the GeniusTech range, including job setup optimization and Genius Run HD, claimed to eliminate bouncing and barring.

Soma announced its Proxima flexo press running up to 400m/min on a maximum print width of 1,270mm, designed for short runs using the company’s Iris automated setup system.

Platemaking also showed advances in the flexpack sector. Xsys demonstrated its ThermoFlexX Catena+ fully automated plate processing line, Woodpecker surface screening patterns for improved quality and reduced ink usage, as well as the expansive portfolio of rotec precision-engineered sleeves and adapters for process optimization. The company also spotlighted the recently launched nyloflex FTV plate, an LED-optimized, inherent flat-top dot plate, engineered specifically for the high-quality flexible packaging market.

On the plate processing side, Xsys launched the Catena ProServX, a cloud-based, real-time equipment monitoring tool for proactive maintenance and quality control.

Materials

Henkel launched Aquence PS 3017 RE, a water-based acrylic pressure-sensitive adhesive designed for the olefinic filmic labels used for wash-off PET bottles. The company says its new adhesive offers excellent wash-off efficiency, even at 65 deg C, for PE facestock. Aquence PS 3017 RE has received the CHI Certificate confirming that the adhesive does not negatively impact the recycling path for transparent PET bottles when used in combination with a PO label. The company says the adhesive resists water whitening and is approved for indirect food contact.

Taghleef Industries featured new Leather and Soft Touch finishes for its Derprosa film 4x4 brand. The company says the coating combines a soft feel with a high level of fingerprint and scratch resistance.

Taghleef’s Derprosa reLIFE BOPP laminated films were demonstrated using ISCC Plus certified resins obtained from post-consumer chemically recycled (PCR) plastic sources, while Derprosa bioBLUE BOPP laminated films use certified resins from residual vegetable origin, including waste cooking oil.

Ancillaries

LED-UV continues to make inroads across all sectors of the package and commercial printing sectors, along with swappable arc/LED systems for transitioning printers to LED.

The newly formed curing business unit of Dr Hönle showcased its new LED Powerline LC HV, a water-cooled LED-UV curing device that can be used both for pinning and final curing.

GEW highlighted its ArcLED technology, with UV Arc and UV LED lampheads that can be quickly interchanged on a press. GEW’s Rhino power control system automatically recognizes the lamp type and switches the power supply accordingly.

IST Metz promoted its HotSwap system for switching between mercury and LED-UV lamps on narrow web presses. The company also presented its UV Analyzer measuring device, a combination of UV app, measuring strips and an Analyzer Stick. The company also promoted its partnership with Kocher+Beck and Heidelberg to offer a comprehensive range of technologies including tooling and UV curing for the press manufacturer.

Pantec showcased its Cheetah N rotary embellishment system applying individual 3D images to shrink sleeves. They are applied by heat and pressure from a carrier film, with speeds of up to 20 images per second, imitating a three-dimensional effect which is not possible using conventional embossing. The company also showed its Rhino flatbed embossing system, suitable for enhancing labels and flexible packaging.

“Automation and robotization were key trends, although these were generally not labels-specific applications, they did point the way forward for all package printing and converting formats”

Prati spotlighted its DigiCompact converting and finishing line for self-adhesive labels and digitally printed flexible packaging. It can convert and finish materials between 12 and 350 microns, switching from self-adhesive paper and plastic labels to heat-shrink and wrap-around labels, with either reel-to-reel, reel-to-sheet or reel-to-label processing. The machine is available in three widths – 370, 400 and 450mm – with working speeds in semi-rotary mode up to 70m/min, and in rotary mode up to 200m/min.

Schobertechnologies showcased its RSM410 IML/MX with Twin Spider designed for high-speed counting, cutting and stacking of in-mold labels with robotic assistance.

Advances in inspection systems also featured, with Esko/ AVT introducing a varnish inspection module for the Esko/AVT Helios system. The add-on module detects issues such as varnish misregister, and partial and full starvation simultaneously with print defect detection.

FAG Graphic Systems showcased an upgraded FAG FluoSP Spectro, a spectrophotometer designed to control invisible fluorescent inks used in anti-counterfeiting applications.

Isra Vision showed a new version of its PrintStar Evo for inspecting flexible packaging, featuring a ‘Static Code Reading’ function checking the legibility of barcodes and QR codes.

Re launched ReVision NET, a web viewing system designed for print quality control.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.