A designer’s perspective: Four innovations at Labelexpo Americas 2024

Columnist Vicki Strull walked the halls of Labelexpo Americas 2024 and takes readers on her journey of discovery through the eyes of a branding and design strategist

I’m not exactly a unicorn at Labelexpo, but I’m not its target audience. After all, designers don’t own the equipment or subscribe to the pre-press software; we work with the printers and converters who own the equipment and subscribe to the software. However, no matter what role you have in the industry, there was no denying the great energy at the show. It’s clear people in this industry were so happy to see each other again.

“I am an outspoken advocate for finishing techniques that create an engaging experience for the shopper and a captivating presence on the shelf”

I spoke at the conference this year, covering one of my favorite topics: creating value with haptics. So, it was a great opportunity to walk the floor and meet several people behind today’s latest label technologies, trends and innovations. Here are four key things I noticed from my design perspective.

1. Embellishments

Embellishments relate to haptics, an essential part of my design work, so naturally, I gravitated toward these booths. I happily noticed that there continues to be a big, positive push for embellishments and finishings as a proven way for labels and packaging to engage shoppers and create positive customer experiences.

I saw several conventional foil-stamping companies with new products and inventive applications. One company that stood out was Infinity Foils. They seem to understand the designer’s needs uniquely because its product line system works by color, not by application. As a designer and brand specialist, I don’t want to think about whether I need a hot or a cold foil; I really just want to make a selection based on the color. With Infinity Foils, I can pick my particular shade of gold or holographic pattern and shade, and they will work with my printer or converter to determine what formula works best for the application. This feels very designer-centric.

I also noticed the beautiful labels on display at the Cartes booth. A particular show-stopper was the multi-dimensional label for PJAFÖC Imperiale, a sparkling wine. The label was covered in gorgeous ‘jewels’ that looked like little domed

gems, and the haptics were like touching mini cabochons. I was surprised to learn that these embellishments were applied digitally.

The fact that stunning embellishments like these can be produced digitally, faster and in-line makes them available to anyone that needs shorter runs, such as start-ups and early-stage emerging brands. At the JetFX booth, another digital embellishment equipment manufacturer, I saw labels for a wide range of product categories, each covering various price points. In other words, embellishments are not just for luxury items but for all types of products. That’s good news for designers and brands who are well aware of the power of touch for consumer engagement.

As some of you may know, I am an outspoken advocate for finishing techniques that create an engaging experience for the shopper and a captivating presence on the shelf. In fact, every package I design these days has embellishments. As an expert in the field, I evangelize how essential it is for a brand to create a haptic experience with packaging. In addition, the foundation of that packaging needs to be a substrate with a surface quality and structure that can withstand the demands of a single or multiple finishing techniques. Why is this so important? Because shoppers develop perceptions about a product based on its label and packaging, those that offer a tactile experience instill confidence.

Without the advanced embellishment technologies that I saw at the show, these types of dazzling labels would typically be produced for only an elite set of very high-end products. After visiting several booths, I imagined how more brands’ products could be elevated in the consumer’s mind with a label similar to the sparkle of that sparkling wine.

2. RFID and NFC

Radio Frequency Identification (RFID) uses radio waves to transmit information, similar to other wireless technologies such as WiFi and Bluetooth. RFID has been around since World War II, when it was used to distinguish allied and enemy aircraft. You probably interact with RFID technology daily because ‘tap to pay’ (contactless credit card payments) is enabled by a type of RFID technology called near-field communication or NFC. An NFC tag is a tiny electrical device that can wirelessly transmit data and interact with other NFC-enabled devices, like mobile phones. While RFID and NFC are not new technologies, there was a lot of excitement at Labelexpo around new applications.

For example, in the Avery Dennison booth, I saw one of the healthcare applications for an epinephrine autoinjector (you may be familiar with brand names EpiPen or Auvi-Q). With NFC technology embedded in the medication’s label, a user can simply bring their phone near the label and it could give them information such as dosing instructions or drug interactions. Another example might be a label for a prescription in pill form; the NFC-embedded label capability could record the day and time that the user took the medicine.

With an NFC tag, instead of using your mobile device’s camera to capture a QR code, all you have to do is tap or wave your phone near the label to get the information or digital experience that the brand wants you to have. Sure, it can take you to a website, but it can also have functional applications that are deeper, faster and more streamlined than a QR code.

From a designer’s perspective, if my client prefers a minimalist aesthetic or wants to reduce a step in the connected print experience, I can specify an NFC label instead of a QR code, for example. However, ever the marketer and designer, it occurred to me that the brand still needs to ‘show’ or ‘tell’ the consumer that there is something for them to do—an action to take (i.e., tap for more information). Otherwise, how would they know that there’s an experience for them? So, a brand will still need to have a symbol of some sort — similar to the universal tap-to-pay icon — if the NFC-embedded label trend continues to grow.

3. Sustainability in the future

According to the experts I spoke with at the show, sustainability in the future will have a different focus. Brands and consumers won’t necessarily be talking about ‘sustainability.’ Rather, they will be more interested in carbon footprint, which is a more accurate way for a consumer to understand the impact that a brand’s label or package has on the environment

Right now, the conversation is often focused on, ‘Is it recyclable?’ or, ‘Does the label or packaging contain post-consumer waste?’ Or here’s the way I talk about packaging: ‘Is it on the biological side of the circular economy or the industrial side?’ (Biological means the packaging is made of materials that eventually and naturally go back to the earth; on the industrial side, they don’t. Some industrial materials may be recycled over and over, but eventually, these materials go into landfills.)

In the future, the perspective might be something like this: A label is made of fiber-based materials – materials that can go back into the earth. Perhaps the material is fresh fiber sourced from the wood pulp of trees in a managed forest that has natural regrowth or is replanted after harvest. But let’s say the label itself does not contain post-consumer waste.

Now, let’s compare that to a label also made of fiber-based material with a percentage of post-consumer waste, but it requires more energy to achieve the quality needed for it to become a useful label or packaging substrate. In this example, one of those labels will have a greater carbon footprint than the other, regardless of their recyclability. And by the way, post-consumer waste does not always translate to ‘better for the environment.’

It’s also important to note that if brands continue to use materials with post-consumer waste and no one is adding fresh fiber to the ecosystem or managing re-foresting, we’d run out of post-consumer waste within seven months!

If consumers and brands start to think about packaging from a holistic carbon footprint impact, then the sustainability measurement they use will change. That, in turn, will filter through to vendors and suppliers and will impact what materials the brands use and how they use them.

Take a supplier like Sappi, whose booth I also visited. Sappi manufactures paperboard and label substrates –both fiber-based and on the biological side of the circular economy. Sappi also operates with one of the lowest carbon footprints in North America for their industry, and they are rated within the top 1 percent globally across a broad range of social and environmental factors.

If I’m a brand manager working with a designer on the packaging, and I need to focus on reducing the carbon footprint of my packaging, Scope 3 emissions become important. A supplier like Sappi helps the brand and the designer work toward those goals.

All this to say, in the future, designers and brands will partner with converters and specify materials based on the carbon footprint required to manufacture the labels and packaging upstream through the supply chain.

As that trickles downstream to the consumer who wants to buy from brands committed to minimizing their carbon footprint, brands will need clear input to speak transparently about how their products impact the circular economy. I imagine future me saying, ‘I’m going to investigate which material is more recyclable and also make sure it takes less energy to create and has a smaller carbon footprint.’

4. Rendering software

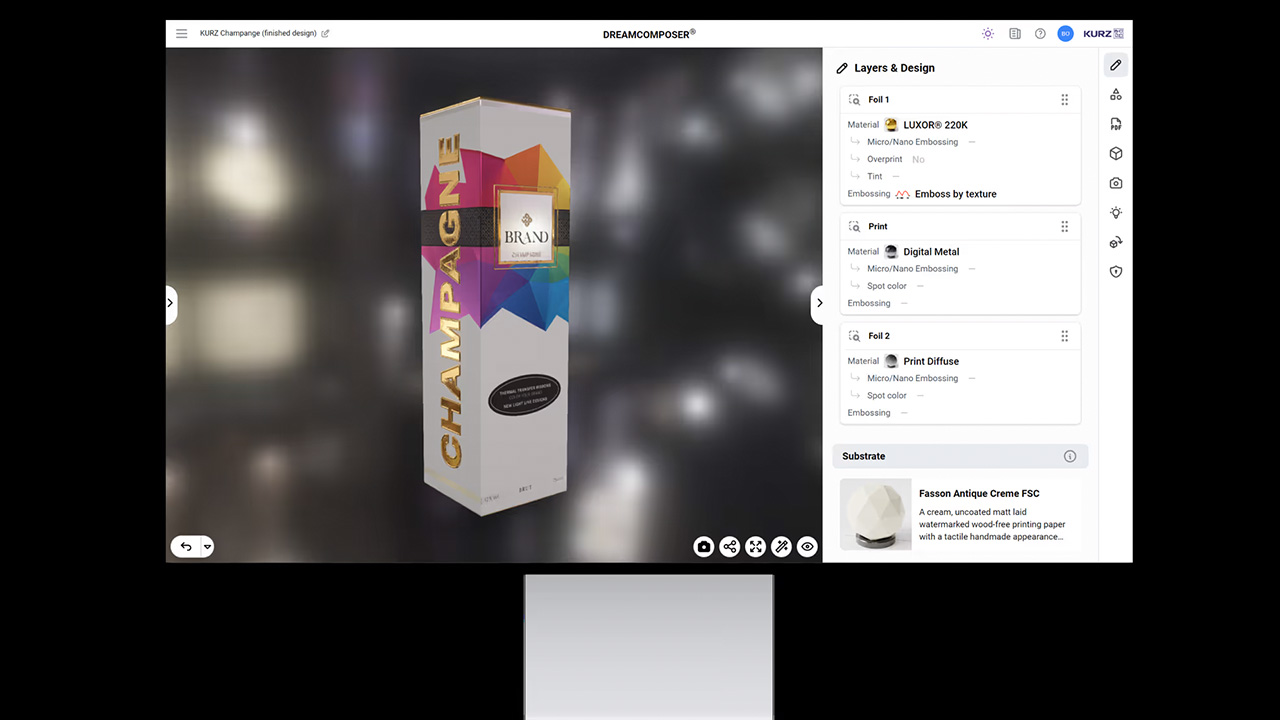

Another cool thing I noticed at Labelexpo Americas was the design-rendering software that many printers and converters use, such as Hybrid Software’s iC3D and Kurz’s Dreamcomposer. I spoke with both companies about the huge strides their software products have made in mimicking embellishments and finishes on digital prototypes in 3D. As a designer, it’s important for me to show my clients a high-quality rendered design — a digital prototype — as a key step in the review and production process. If I specify a spot gloss or foil stamp on a label, I can typically visualize it, but my clients may not. At Labelexpo, I saw that the software continues to improve to simulate the shine, sparkle, finish, and texture — the haptic quality of the packaging. This is critically important in conversations with my clients; it helps me show-and-tell brands about the importance of embellishments for engaging shoppers and creating exciting and unique consumer experiences.

Vicki Strull is a design strategist with more than 25 years in the industry designing packaging, brand identities and a multitude of packaging and online touchpoints. Vicki co-founded MarketWise Academy to help fellow designers and marketers accelerate their impact, level up their design strategies, and thrive in a world dominated by business. That’s where the idea for The Business 6 originated.

To learn more about The Business 6 and other strategies, visit marketwiseacademy.com or contact Vicki directly at vicki@vickistrull.com

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.