Allen supplies coding system to BASF

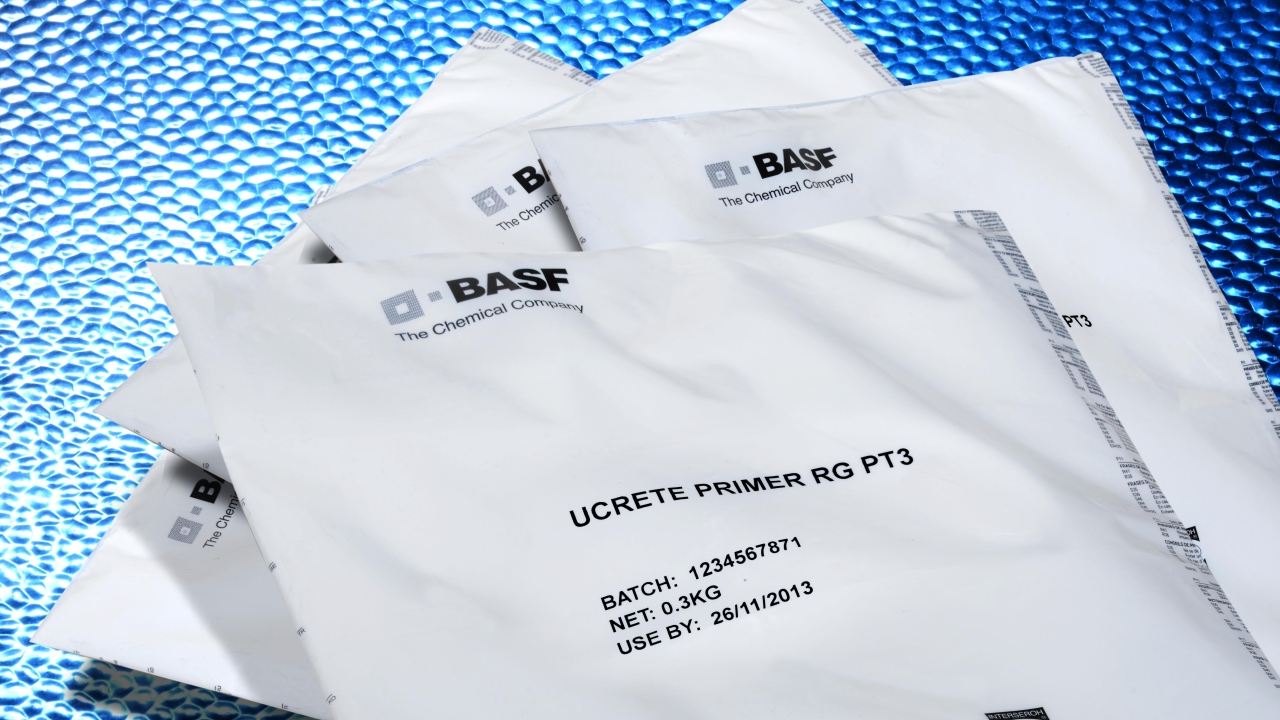

Allen Coding Systems has installed a high-speed NG4IM thermal transfer coder at BASF that will be used for labelling chemical systems and formulations for the construction industry.

Suitable for printing fixed and variable text, data and graphics, use-by dates, real time, batch codes, bar codes and much more, the NG4 is installed on BASF’s plastic film de-coiling unit at its production facility in Redditch, UK, operating at 15 cycles per minute.

Targeted specifically towards chemical, agricultural and hardware manufacturers who require large amounts of information to be applied to packaging/labels, the NG series is being used by the concrete flooring manufacturer to print product descriptions and best before dates on to cementitious materials.

The NG4 features a 450m ribbon capacity on a cassette, a 300dpi thermal printhead and intermittent print speeds of up to 500mm per second.

David Williams, EHSQ/engineering manager at BASF UK, said: ‘Our previous printer had been supplied by Allen Coding so when it needed upgrading we went with their recommendation to replace it with an NG4 model, because of its ability to withstand the demands of a dusty, high production environment.

‘The new coder produces clean, legible print on to an area 107 x 90mm, helping to increase the efficiency of our packaging process.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.