Fife launches two automated guiding products

Fife SmartDrive Actuator and Fife GuideLine HR were developed for enhanced accuracy and faster web speeds.

GuideLine HR

Maxcess has launched Fife SmartDrive Actuator and Fife GuideLine HR (high-resolution digital sensor) developed for enhanced accuracy and faster web speeds.

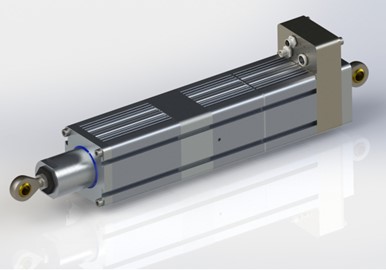

Featuring a fully integrated controller, drive and motor, the Fife SmartDrive Actuator is an easy to install product for automated edge and center guiding in converting, laminating, and printing applications.

Its speed, responsiveness and enhanced accuracy continuously corrects material position errors. The direct-drive gearless design maintains maximum thrust and speed throughout the entire stroke with stroke lengths up to 400mm. Regardless of mounting position, the integrated servo center and zero-drift, absolute position encoder ensures no need for recalibration.

The Fife GuideLine HR builds on the success of the launch of the Fife GuideLine Digital Sensor. The original Fife GuideLine can guide to lines, edges of lines and graphic patterns on the fly, including bar codes.

GuideLine can be used in edge guiding transparent films, low contrast conditions, closely co-located patterns, and with black-on-black applications where traditional line sensors do not work. Its increased accuracy and intuitive touchscreen operator interface makes the Fife GuideLine suitable for the most demanding guide applications.

Fife GuideLine HR builds on those unique attributes with even higher resolution (0.002mm for GuideLine to 0.0008mm for GuideLine HR). It is design specifically for applications where the highest accuracy and repeatability are required.

‘These two new innovative solutions from Maxcess and Fife provide the automated solutions our customers have been asking for to conquer the most demanding and challenging guiding applications requiring industry leading accuracy and repeatability,’ said Rob Stoebick, global product manager at Fife Guiding Solutions.

‘Whether you’re guiding to printed materials on a number of traditional substrates like paper, film and foil, or more exotic materials used in battery, optical films, black-on-black materials, and fuel cell production, Maxcess and Fife can provide automated solutions to help the customer work better, faster and smarter with strong ROIs,’ concluded Stoebick.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.