Labelexpo Americas 2024: A-Z technology preview

Labelexpo Americas 2024 promises to be a showcase of technological innovation. This year’s event is set to spotlight the latest advancements in technology that will transform the label industry with trends to be found in flexible packaging, RFID, sustainability, automation and more. This comprehensive preview is aimed to guide you through the technology and innovations on display at Lablexpo Americas 2024, on Sept 10-12 at the Donald E Stephens Convention Center in Rosemont, Illinois.

3M - A B Graphic International (ABG) – Alphasonics - Aluminium Féron – Actega - Anytron - Apex International - Applied Molecules – Appvion - Armor IImak – Artience - Arrow Systems - Asahi Kasei Corporation - Ashe Converting Machinery - Astron Packaging – AstroNova - Avery Dennison - Axicon Auto ID – Beontag - Breit Technologies - Brodbeck Maschinenbau – BST - Bobst – Boingtech - Brotech (Shenzhen Brotech Digital Graphics) - Buskro - BW Converting – Canon - Cartes – Cerm - Channeled Resources Group - Chem Instruments - China Aebo Science Technology - Coatings & Adhesives - Colordyne Technologies – Color-Logic - Comexi - Cosmo Films - CTS Industries - Cyngient - Daco Solutions - Dantex Group - Darui (Ningbo Darui Automation Equipment) - Decosystems - Delta ModTech – Digimarc - Digital Print – Dilli – Dienes – Dipco – DMS – Domino - Dongguan Bengraphic Printing Equipment - Double E Group - Double H Plastics - D.P.R. Labeling – Durico - DuPont - Durst Group – Eaglewood - Edale - Elkem - eProductivity Software - EMT International - ETI Converting Equipment - EyeC - Excelitas Technologies - Fangda Packaging - Fedrigoni Self-Adhesives - First Crown Enterprises Holdings - Flexcon Company - Flexo Wash - Flint Group - Flora - Fujifilm - General Inkjet Technology - GEW - Ghangzhou Super Color - GIC Online - Global Vision - GMerix - GMG Color Americas - GSE Dispensing - GTI Graphic Technology - Graphimecc Group - Grafisk Maskinfabrik (GM) – Grafotronic - GTI Graphic Technology - GoDEX International – Gonderflex - GPPE Automation Group - Guangzhou Xinzhu Adhesive Material - Hangzou Todaytec Digital - Harper Corporation - HB Dynamics - HB Fuller - Heidelberg / Gallus - HMJ Tech - Henkel Adhesive Technologies - Hongkong Jiuheng Group - Hontec Industries - Hybrid Software - HP - Hubei Hyf Packaging - Hybrid Software - In-Mold Decorating Association (IMDA) – Inkstar - Infinity ID – Innovia - Interactive Inks & Coatings - International Media Products - INX International Ink - Jennerjahn Machine - Jiangxi Zhenguan New Material - Jinda (Shanghai Jinda Packaging Materials) – iSys – Jalema - JCR Pack – JetFX - K Laser Technology - Kampf Machinery - Karlville - Klöckner Pantaplast - Kocher + Beck - Konica Minolta – Kroenert – LaserClean - Lecta - Lemorau - Lemu Group – Lombardi - Lundberg Tech – Mactac - Mark Andy - Martin Automatic - Maxcess / Rotometrics - Meech International – MicroDynamics – MoistTech – Mühlbauer - Nastar - Natural Ink - Nazdar Ink – NeuraLabel – Nilpeter - Ningbo Jingwei Systemtechnik – Nobelus – Omet - OneVision Software - Phidastien International - Polyart Group - PPG Teslin – Prati - PRI Plus – Priber – Prisco - Pulisi (Guangzhou Pulisi Technology) - QC Electronics - QSPAC Industries – Re – Retroflex - Rhyguan Machinery - Ricoh Electronics - Rigaku Technologies - Rosas Machinenbau – Rotometal – Schober - Screen Americas - Shandong Hoaco Automation Technology – Siegwerk - Smart Solve - S-One Labels & Packaging - Stock PKG – Styers - Sun Chemical - Tailored Chemical Products – Tamarack - Techkon - Tectuprint - Telstar Engineering - Tesa tape - Thwing-Albert Instrument Company - Tootech - TR Electronics - Troika Systems - Ultimate TechnoGraphics – Unilux - UPM Raflatac - UPrint Technologies - Uvitec Printing Ink – Velox – Vemax – Voyantic - Wausau Coated Products - Wilson Manufacturing Company – Wink - Wuhan Golden Laser – Xeikon - Xsys - X-Rite - Yupo Corporation - Zeller+Gmelin - Zhejiang Benyuan Plastic Paper Technology - Zhejiang GaoBao Machinery - Zhejiang Kete Machinery - Zhejiang Wanbaolong Adhesive Products

3M

Booth 1617

3M showcases a comprehensive range of products tailored for critical markets that demand reliability and durability, including the 3M Versatile Print Topcoat, offering exceptional printability and durability and is designed for various printing methods.

The booth visitors can also explore the company’s selection of solvent and solventless adhesives crafted to meet the diverse needs of OEMs and graphic converters.

A team of experts is available on-site to provide application assistance and share technical knowledge of 3M’s product portfolio.

A B Graphic International (ABG)

Booth 3223

ABG showcases a range of innovations including NSU Lite, a new addition to the company’s non-stop winding range. The system is demonstrated in-line with ABG's fourth-generation Converter platform and the recently launched Vectra AutoSet turret rewinder.

Additionally, ABG promotes the flagship Digicon Series 3, including the ABG Connect workflow for automation and streamlined processes. A full beverage specification Digicon is also on display.

Key technologies showcased include a DigiLite, DigiLase and shrink sleeve machinery.

Alphasonics

Booth 3010, 3031, 434, 319

Alphasonics group showcases medical-grade cleaning technology designed for cleaning anilox rolls. Guided by its work cleaning surgical instruments to near-sterile levels, Alphasonics is carrying out demos throughout the show across several booths.

Also on show is the PCX system, designed for full automation of the plate cleaning process, which encompasses washing, rinsing and drying in a convenient and thorough process. Alongside this is Plaeto, a fully automated plate-loading system which can load up to 30 plates consecutively into any plate-cleaning system using patented technology.

Finally, the 2024 edition of the show will introduce a new development from the company that aims to reduce water-based ink waste by more than half. While details are being kept under wraps for now, Alphasonics promises a game-changing product that will be unveiled as the show opens.

Aluminium Féron

Booth 1551

Aluminium Féron, a first-time exhibitor, showcases a range of products for labels and tags, including synthetic paper Monotex for digital printing as well as substrates for durable applications such as tear resistance, high-temperature resistance, metal detectability or RFID protection. Féron's Monotex and Tritex products, showcased at the booth, can be utilized across several industries, including horticulture, construction, apparel, healthcare, leisure and tourism, logistics, chemicals, automotive and steel processing.

Actega

Booth 711

Actega promotes its low-migration inks and specialty coating effects for labels and flexible packaging, along with its Signite and Ecoleaf technologies.

Ink and coatings developed for the labels and flexible packaging industry include Actexact Safeshield inks for low-migration applications, LED-UV inks and coatings, haptic and optical effect coatings and opaque whites for labels, shrink sleeves, tubes and pouches.

‘Actega’s SafeShield Inks assure converters and brand owners of compliance with stringent regulatory requirements, regionally and globally,’ said Mell C Bishop III, vice president of flexible packaging, and global market manager for labels at Actega.

‘Ecoleaf is a mindful metallization technology in label embellishment that minimizes waste and optimizes resources. Brands can benefit from high-quality metallic finishing while reducing their environmental footprint,’ commented Paolo Grasso, sales director for Ecoleaf at Actega.

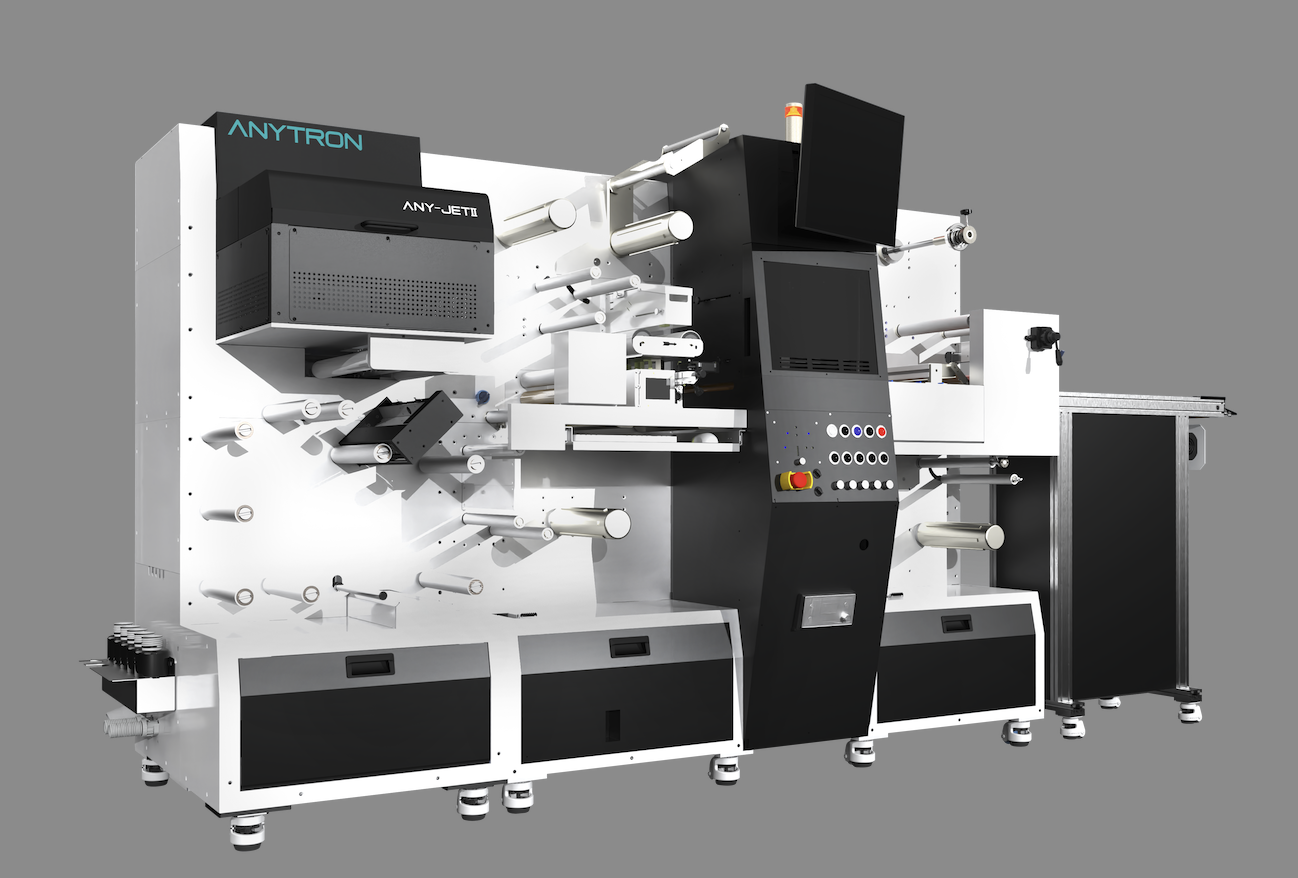

Anytron

Booth 5707

Anytron showcases the Any-Jet II Plus, the extended version of its in-line digital label press, the Any-Jet II.

This machine offers printing, laminating, laser cutting and the capability to deliver roll-to-roll labels and full-cut stickers along a conveyor. In addition to its flagship machines, Anytron also presents new applications for Any-Press, a compact CMYK+W, 13in toner printer.

Apex International

Booth 1442

Apex International exhibits anilox rolls and sleeves engineered for label, package and print applications, including the GTT 2.0, developed to mitigate liquid turbulence and increase quality and performance at top press speeds. According to Apex it reduces ink spitting, mottling, pinholing, plugging and dot gain.

The company also showcases Apex UltraCell engravings, engineered ultra shallow for greater ink release and easy cleaning, including Hex 60°, 75°, longcell, trihelical, channelox, and 45° quad. Labelexpo visitors are also invited to see Apex engravings in detail through the Veritas inspection system.

Applied Molecules

Booth 3814

The company showcases its digital technology primers and coatings for UV inkjet and toner printing, laminating adhesives for all printing technologies, release coatings and IML coatings.

Appvion

Booth 702

Appvion promotes recently launched EarthChem, a sustainable direct thermal product portfolio featuring a phenol-free chemistry alongside other sustainable features.

Within this portfolio, the company launches the Résiste 165 E, specifically designed for package delivery and logistics labels.

Armor Iimak

Booth 535

The thermal transfer ribbon specialist is showcasing its entire range of products and promoting sustainability initiatives, including reducing plastic usage by developing a new generation of ribbons produced on a 4µ PET base film. This innovation results in up to 12 percent plastic reduction per roll.

The company also showcases its patented SolFree product, a 100 percent solvent-free industrial process for its thermal transfer ribbons with reduced CO2 emissions.

Artience

Booth 258

artience (formally Toyo Ink Group) showcases a wide range of printing inks, packaging materials, colorants and polymers. Toyo Ink America's Pressure Sensitive Adhesive Division's solvent and emulsion acrylic polymers represent a broad range of resins used in high-performance adhesive products for tapes, labels, decals, industrial foams, medical, graphics, as well as other end-use applications.

Arrow Systems

Booth 5703

Arrow Systems promotes the latest water-based pigment inkjet printing, along with a range of digital finishing equipment. The ArrowJet range delivers 1,600 x 1,600 DPI resolution and print speeds up to 60m/min, while using Nestlé and Swiss-compliant, water-based inks.

The ArrowJet 330R M Series, which makes its US debut, features a modular design, allowing customers to integrate a range of in-line technologies such as priming, varnish, lamination, and slitting.

The company also showcases the EZCut range of digital knife-finishing equipment. The latest upgrades to the EZCut 330R+ include auto knife adjustment, roll-to-part option and auto-job change. The EZCut 350R+ also makes its debut.

Asahi Kasei Corporation

Booth 937

Asahi Kasei Corporation showcases AWP-CleanFlat and AWP-DEW flexo plates, certified Carbon Neutral products. Additionally on show is the AFP-R, which was awarded the FTA Sustainability Excellence Award in 2024. This solvent-washable plate offers a reduced environmental impact. Asahi also promotes its AWP-Loop, a wastewater recycling system based on Asahi Kasei microza technology.

Ashe Converting Machinery

Booth 918

Ashe Converting Equipment demonstrates the Opal glueless turret rewinder with patented cut and transfer technology.

Booth visitors can also see the Opal ISR full 100 percent label inspection slitter rewinder and a range of converting lines with full rotary die-cutting along with the wide web range of equipment.

Astron Packaging

Booth 3708

Astron Packaging showcases its pressure-sensitive labelstock brand Tackify launched by the new Coated Products Division of the company. Astron promotes Dry Feek Void, an overt brand protection technology, which leaves a dry adhesive residue in a VOID pattern on the substrate when the label is peeled off. Also on show is the Customized Void, an overt brand protection product where the conventional VOID pattern can be replaced with customized artwork and colour.

At the booth, there is also Ultra Destructible Vinyl, an overt brand protection product. Due to its' eggshell-like' face construction, it is almost impossible to scrape off from the substrate.

VeilReveal, also promoted at the show, is a covert product where a customized artwork printed on a residual face layer is revealed on the substrate upon label tampering.

Astron also showcases hybrid acrylic adhesives for challenging applications like in-line molded containers and corrugated boxes, and PCR PET Films with 40 to 8- percent PCR waste.

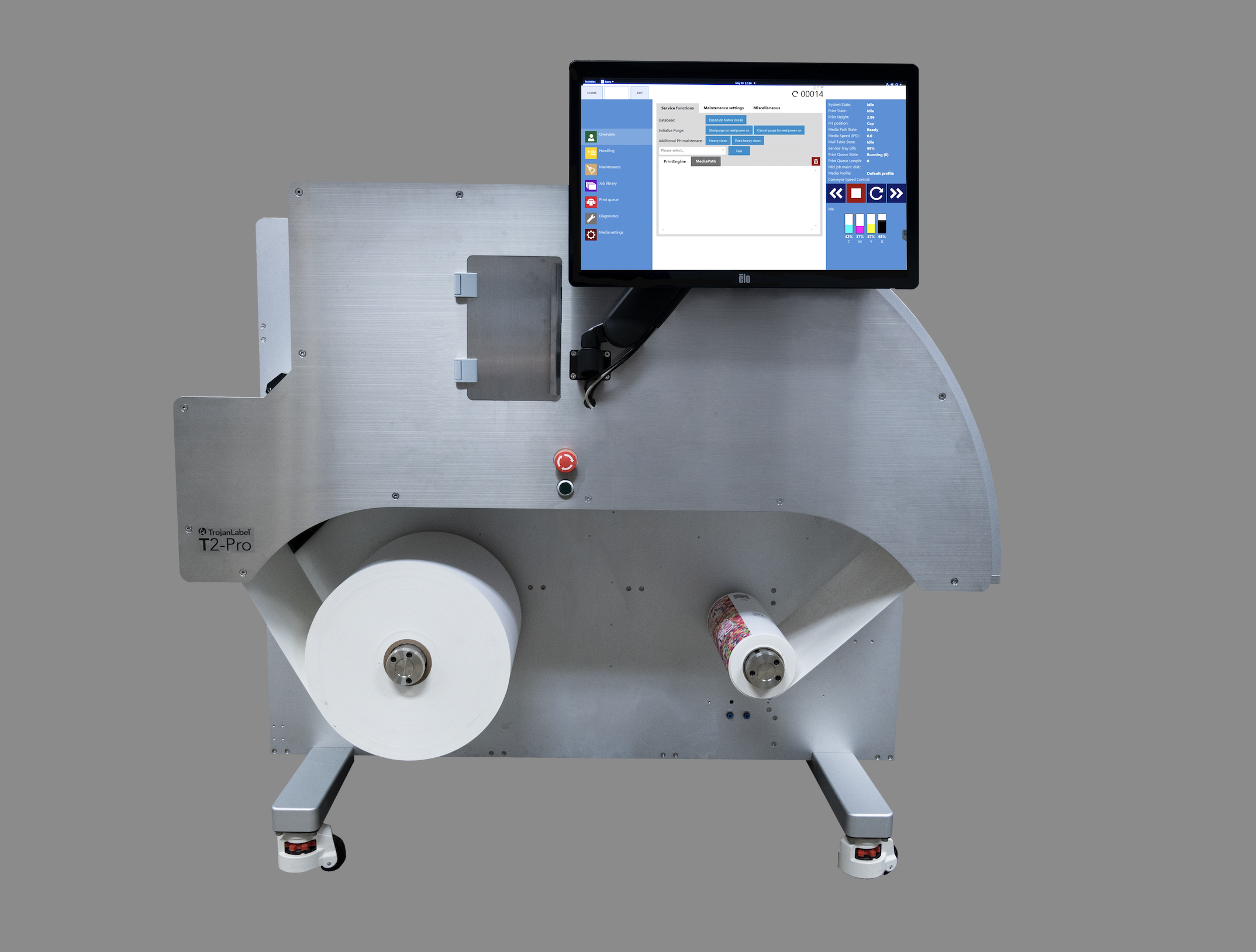

AstroNova

Booth 5622

AstroNova and its newly acquired subsidiary, MTEX NS, showcase a range of products for the digital label printing industry. Among the highlights are the TrojanLabel T2-PRO and Atom 3 + Cutmaster.

Mike Natalizia, CTO of AstroNova, said: ‘The T2-PRO had been in active Beta trials at several customer sites since the beginning of 2024. We have now started booking orders for commercial units, and shipping to our early customers has already begun since August 2024.’

The Atom 3 paired with the Cutmaster demonstrates AstroNova’s commitment to innovation for in-house professional label printing and finishing using digital inkjet technology.

Avery Dennison

Booth 119

Avery Dennison promotes a range of industry technologies based on pressure-sensitive technology including RFID and sustainable, lower carbon alternatives. Booth visitors can discover products that enable recycling or reuse and learn how they can contribute to a more sustainable future.

‘Avery Dennison is focused on addressing the key challenges facing our customers and the industry as a whole,’ said Anh Marella, vice president of marketing at Avery Dennison. ‘We are looking forward to a highly interactive booth this year that allows us to not only show solutions and products but also connect with customers and continue building relationships.’

Axicon Auto ID

Booth 6011

Axicon Auto ID promotes a range of verifiers fully compliant with the international ISO/IEC standards for linear, matrix and DPM barcodes. These verifiers measure the quality of printed barcodes on all levels of product packaging.

On show is the Axicon 15000 series, a linear and 2D barcode verifier. It uses an array of LEDs and a CCD-based sensor to capture each barcode image before it is analyzed. It can verify multiple barcodes in the same field of view, whether they are 2D or linear codes. The software also includes the option to analyze captured images of direct parts marked Data Matrix and QR codes.

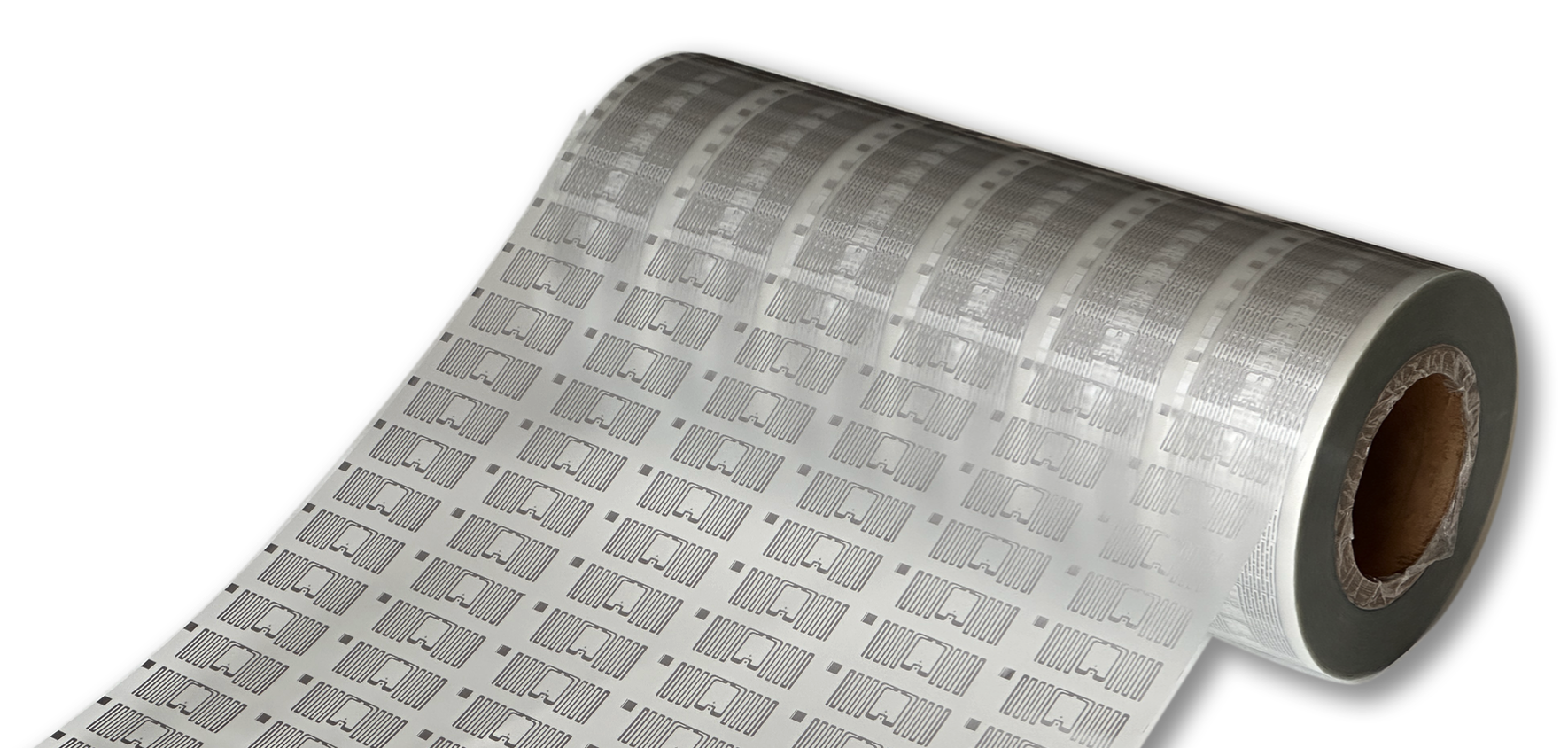

Beontag

Booth 840

Beontag showcases its extensive portfolio of paper and film facestocks and adhesives, including specialty label materials for wine bottles, removable adhesives and linerless options.

Beontag launches its new Wash-Off portfolio for PET bottles. It is the latest innovation in the company's growing category of sustainable innovations and aligns with its ongoing ESG agenda. When immersed during the PET recycling process, Wash-Off labels peel off easily, preventing contamination and allowing a second or third generation of PET to be repackaged and reused.

In addition, Beontag will showcase its range of digital transformation capabilities. These include the innovative ECO tags and the range of ARC-certified products that form a key enabler of all UHF and RFID services.

Ricardo Lobo, CEO of Beontag, commented: ‘At Labelexpo Americas 2024, we see a terrific opportunity to highlight Beontag’s diverse portfolio in an important market for our company. Our footprint in the United States is growing, so this feels like the right time for us to take this step. I look forward to a productive conference, making new connections and re-connecting with customers, clients, and friends as we continue to grow our customer base in the USA and beyond.’

Breit Technologies

Booth 5801

The company promotes its cast and cure technology, which adds holographic and tactile elements and can be applied in transparent flood coat and spot applications.

It comes in a variety of patterns, can be customized for brand enhancement and protection and reused over five times. Breit Technologies also shows dedicated equipment for both sheet-fed and flexo presses.

Brodbeck Maschinenbau

Booth 6336

Brodbeck showcases Multi ID Core Cutter UNI 1000, a machine with the patent-pending design of a single-cutting mandrel suitable for all core diameters between 25 and 180 mm.

Once the desired cutting length and quantities are keyed in and the parent tubes fed in, the machine cuts and discharges cores without additional setup.

BST

Booth 837

BST North America exhibits its TubeScan 100 percent print inspection system developed for a wide range of applications. The TubeScan Dynamic Job Change technology developed in collaboration with Hybrid Software, which is also on show, works with customers’ pre-press software to efficiently manage digital workflow.

Bobst

Booth 5601

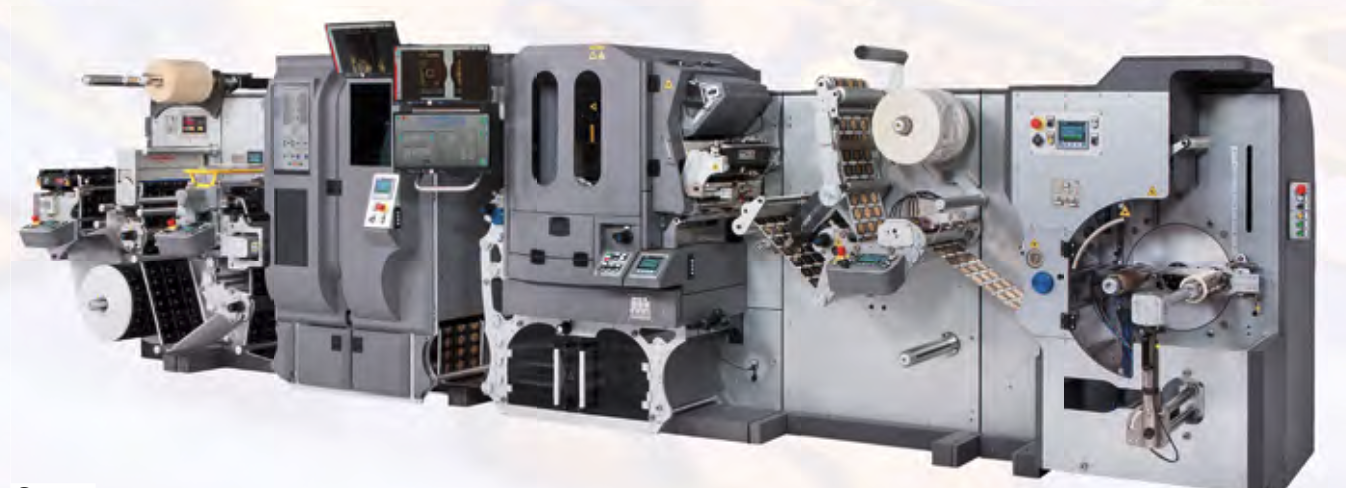

Bobst showcases Digital Master 340 demonstrating its all-in-one label production concept with printing, finishing, die-cutting and quality control in a single pass. It features Accucheck, a proprietary in-line inspection and calibration system that comes with digital automation on all print and finishing modules, controlled via a single interface with cloud connectivity.

Accucheck has been updated with automatic quality inspection setup and job queue synchronization. Calibration improvements include a new color uniformity feature and advanced color-to-color registration.

Bobst experts are also discussing oneECG, an extended color gamut technology developed for in-line flexo presses offering savings, sustainability benefits and improved color consistency.

At Labelexpo, visitors can also experience Bobst Connect demonstrations showcasing the latest features, including a major update to the equipment monitoring capabilities providing detailed data insights, performance management KPIs and job inspection reports.

Boingtech

Booth 5112

Boingtech showcases its RFID manufacturing know-how and innovative design expertise by promoting its wide range of standard and customized RFID products, such as inlays, labels and tags. For customers focused on sustainability,

Boingtech prepared paper-only (PET-free) inlays and labels. The company also showcases RFID technology for difficult environments such as metal or wash-resistant applications.

Brotech (Shenzhen Brotech Digital Graphics)

Booth 5603

Brotech promotes a full range of converting, finishing and hybrid digital and finishing products for the label and flexible packaging industry, especially digitally printed labels.

The company showcases Brotech SDF Plus, which features a new modular and platform-based design. One of the SDF Plus machines demonstrates high-speed processing over 300 cuts per minute, while the other showcases digital embellishment processes. The digital embellishment unit can be applied to digital white, digital metal, and digital varnish, providing customers with more diverse and higher-quality production options.

The company also promotes Brotech SMS Shrink Sleeve Label Finishing System, specifically used for seaming PVC, PET, PE, POF and other color-printed shrink film materials into roll-shaped packaging materials.

Buskro

Booth 6412

Buskro launches of two new products at Labelexpo Americas 2024.

The first is the new DLP 1085 digital label press, featuring a 4.25-inch color printhead, automated maintenance station and RFID unit, designed for variable and short run label printing. It offers print at speeds of up to 1m/s and produces over 60,000 labels per hour.

Additionally, Buskro introduces the Titan wide print 11.75-inch CMYK Aqueous printhead, suitable for printing high-quality graphics and variable content on corrugate and packaging materials. It offers print at resolutions up to 1,200 x 1,200 DPI and production speeds of 0.6m/s. The Titan uses eco-friendly water-based inks.

BW Converting

Booth 842

BW Converting promotes Paper Converting Machine Company (PCMC) and Baldwin Technology products.

PCMC spotlights the ION hybrid press and Meridian Elite, a laser anilox roll cleaner developed to provide optimal print performance with no water, heat, chemicals or air supply required.

PCMC also showcases the Fusion press series, which incorporates energy and time-saving features like automatic drum cleaning and impression setting, reducing downtime and the ELS Max advanced in-line inkjet printing product designed for fast changeover, reduction of waste and quick setup time.

Also on show is Baldwin's new PQV 4.0 process-optimization tool, which has been developed to enhance the inspection process with its automated, intuitive user experience. It reduces the risk of human error and improves accuracy. PQV 4.0 can detect errors and faults with micrometer precision and provides a detailed report for correcting the mistakes.

At Labelexpo, Baldwin presents the Corona SlimLine surface treatment, which bonds ink onto plastics, making it suitable for label printing and narrow web applications. The compact system provides power, electrode settings, and comfortable and ergonomic handling, operation and cleaning.

The company also highlight the new Baldwin Unity LED curing system, designed for various presses and finishing equipment, which maximizes performance while reducing power consumption by up to 60 percent compared to traditional curing methods.

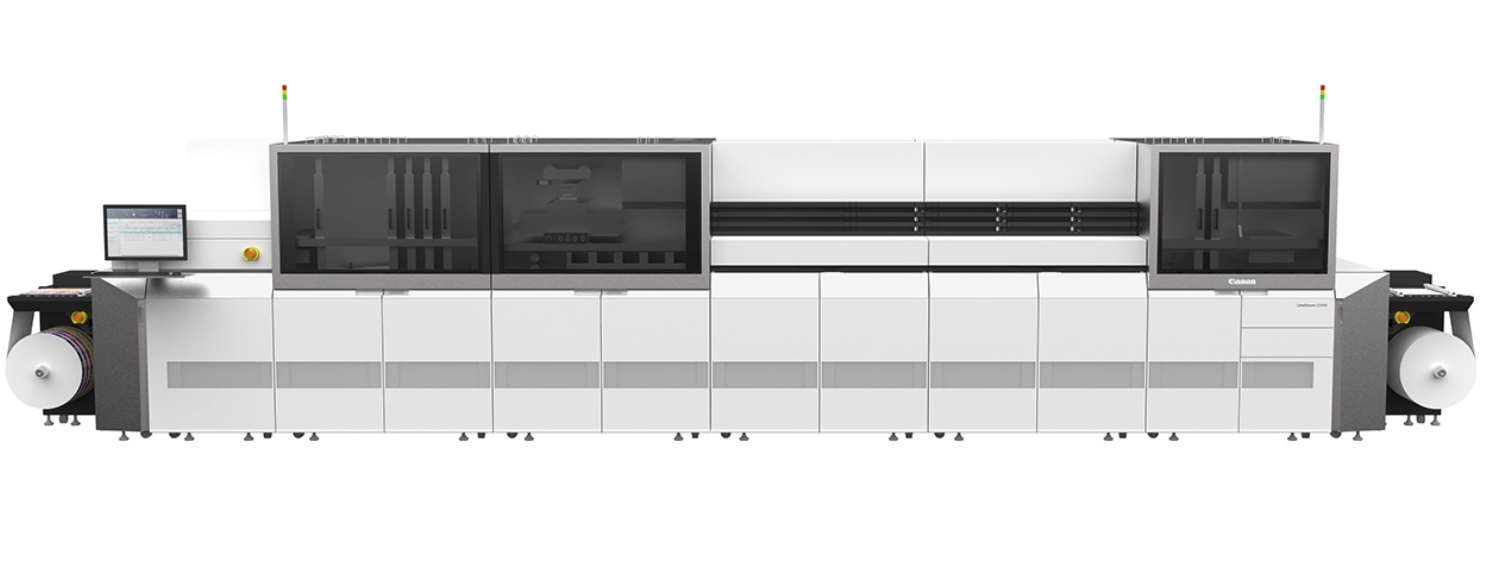

Canon

Booth 5803

Canon displays a diverse portfolio, including desktop printers and high-production presses. Among the highlights is the North American preview of the LabelStream LS2000 five-color inkjet digital label press. It will be available to the US in the second half of 2025, and features many newly developed Canon technologies, such as high-density aqueous ink, printhead, advanced fixing system and various automation features designed to support efficient production.

The company will also be promoting the LX-P5510, LX-D5500, and LX-P1300 dye and pigment-based inkjet desktop printers developed to meet the needs of on-demand in-house printed labels.

The Colorado M-series roll-fed printer, a modular 64-inch roll-to-roll printer with optional UVgel white ink, will also be available in the booth. This printer will showcase a wide range of label printing applications.

‘We are excited to show our diverse portfolio of offerings serving the label converting market implementing our inkjet innovations to support the digitization in this segment and Labelexpo is a great opportunity to demonstrate our capabilities,’ said Shinichi ‘Sam’ Yoshida, executive vice president and general manager, Canon USA. ‘We look forward to the North American preview of the upcoming LabelStream LS2000 digital press showcasing its ability to deliver high-quality, efficient, and versatile label production.’

Cartes

Booth 5403

Cartes shows the Gemini Series GE363WJL machine combined with Jet D-Screen, a semi-rotary flexo and a laser converting system for no tooling operation.

Also on show is the GT365HFSRH model, a part of GT36O portfolio set up with the hot stamping and embossing units, a semi-rotary flexo unit, a silk screen unit, a semi-rotary die-cutting unit and the labels-on-label and cut-off window systems.

The company promotes its latest entry-level, compact GE261L Star Line Finally laser converting machine.

Cerm

Booth 437Cerm launches its AI-powered Scheduling Optimizer. Powered by AI algorithms, it streamlines long-term planning while allowing planners to focus on short-term adjustments tailored to specific production needs. According to the Cerm, the product will improve efficiency, reduce costs and prepare businesses for the future of production management.

The attendees can see the live demonstration of the Scheduling Optimizer during Cerm studio sessions, led by Peter Heyse, director of product development at Cerm. The sessions will provide insights into how the AI-driven Scheduling Optimizer can support the scheduling process.

During the live demonstrations, attendees can see how the tool helps in production planning by handling long-term scheduling and allowing planners to focus on a 'frozen window' of short-term tasks, adjusted to pre-defined parameters. The AI capabilities of the product enable it to adapt to a wide range of production scenarios, ensuring that print shops can tackle any challenge with greater ease and accuracy.

Sebastiaan Hermans, marketing manager at Cerm, said: ‘Whether you’re handling complex production schedules, short-run orders, or high-end finishing, our Scheduling Optimizer delivers the most efficient and effective schedule tailored to your business’s unique needs.’

Channeled Resources Group

Booth 1211

Channeled Resources Group showcases a diverse inventory of blank labels, including commodity-sized blank labels for thermal transfer and direct thermal applications.

The company also promotes its pressure-sensitive roll label materials, including the Channeled Choice line and Channeled Value line, which boasts a B-grade label stock and setup materials.

Chem Instruments

Booth 5723

The company promotes advanced adhesive testing products tailored for the label and adhesive industry., developed to optimize adhesive processes, ensure product performance and achieve superior results.

The company also sample preparation instruments and accessories, such as roll downs, laminators and coaters.

China Aebo Science Technology

Booth 157

Aebo promotes its low-cost, standard and premium wax-based bar code ribbons. The company maintains an inventory of slit ribbons and jumbo rolls at its Charlotte, NC distribution center. A team of specialists is available at the booth to guide visitors through its portfolio.

Coatings & Adhesives

Booth 3722

The company promotes a full range of coatings and adhesives as well as polymer production for specialized applications. Products that meet the latest regulatory requirements for UV and dual-cure coatings and adhesives for multi-layer labels, shrink sleeves, and others are just a few technologies featured on display.

Colordyne Technologies

Booth 5923

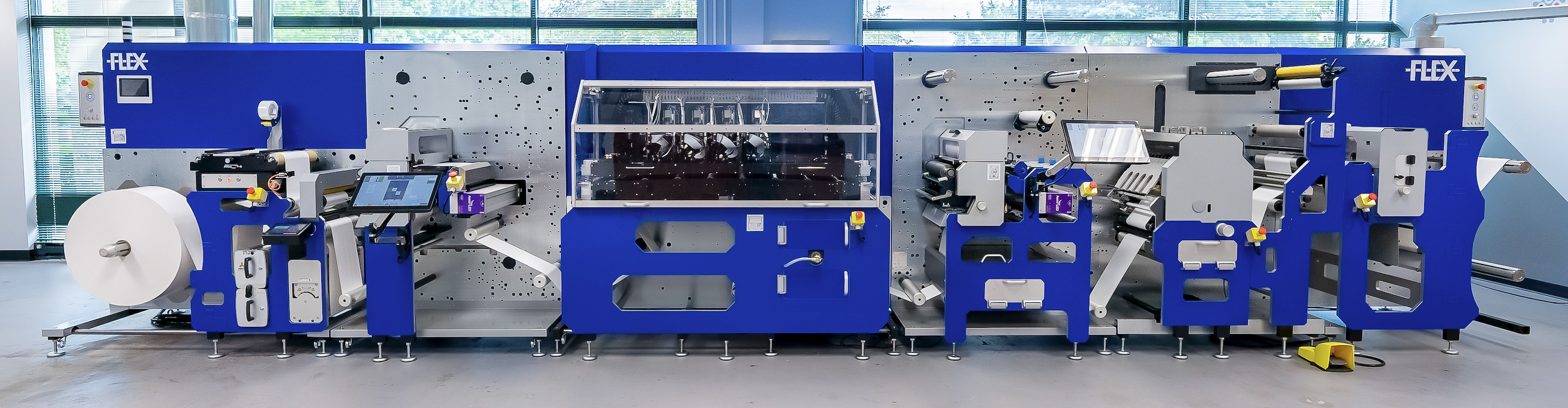

Inkjet printing technology specialist launches the Flex Digital Solution developed in partnership with Oldham Group and Grafotronic. The new technology integrates the precision and flexibility of digital printing with the reliability of traditional flexographic printing and converting. It offers efficiency, modularity and quality, designed specifically for narrow-web label and packaging providers.

Color-Logic

Partner booths

The company and its partners showcase new technologies designed to elevate the quality and impact of label production. Attendees at Labelexpo Americas 2024 can see how the Color-Logic advanced metallic color system and special effects can transform labels into extraordinary visual experiences.

By visiting Color-Logic partners at the event, label printers can gain insights into the latest industry trends, including enhanced print quality using metallic colors and special effects to produce stunning visual effects, adding a premium touch to labels.

The company showcases how innovative technology, such as new presses, integrates with the Color-Logic process metallic color system to produce print embellishments with just one pass.

Labelexpo visitors can learn about technologies that enhance label aesthetics and streamline production processes, reducing waste and improving ROI.

Color-Logic press manufacturer partners at Labelexpo Americas 2024 provide samples that demonstrate print embellishment production in a fraction of the time associated with manual or post-press methods.

Comexi

Booth 3614

Comexi presents its labeling industry technologies, including offset printing with a central impression cylinder, which adapts to the time-to-market concept and offers reduced costs and environmental impact with the solventless EB offset inks.

Cosmo Films

Booth 130

The company presents various products, including pressure-sensitive facestock films, shrink sleeve label films, shrink wraparound labels, and IML label films. These films are designed for multiple applications and ensure good print quality and durability. The company also displays its high-barrier label films, high gloss films, matte-coated films, and PVC-free films for graphic applications.

On show is also a range of Cosmo synthetic paper (CSP), an alternative to traditional paper in commercial printing, tags and labels, retail and packaging, identification and credentials and outdoor applications.

Sandeep Dutta, president of overseas operations at Cosmo Films, said: ‘Labelexpo Americas provides a platform for showcasing innovation and fostering industry connections. Our presence here highlights Cosmo Films' commitment to the Americas market where we have a strong presence with local warehousing and distribution and continue to innovate to meet evolving market demands. We're excited to present our focused product portfolio to the North American market, demonstrating our expertise in labels, synthetic paper, lamination, and packaging solutions.’

CTS Industries

Booth 1316

Celebrating its 44th anniversary, CTS Industries promotes the Pro-Lite HD laser engraved ceramic anilox roller developed to offer ease of care and cleaning. Expanding on achievements with EZ View Pro engraving specs, it helps operators view details such as LPI, BCM, and Serial ID. Also on show is the RollerTec servicing narrow web rubber rollers from 35 to 85 durometer.

Cyngient

Cyngient will highlight the ‘art of embellishment’ and coatings for prime and shrink sleeve labeling, featuring a full portfolio of specialty products. Offerings include primers, raised coatings, soft touch finishing, glitter effects, glow-in-the-dark inks and a comprehensive range of fluorescents, among many others.

Andrew Wasserman, managing partner at Cyngient, commented: ‘We’re thrilled to be exhibiting once again at Labelexpo Americas. Our team of experts is ready to welcome printers and converters, as well as brand owners, to learn about our customer-centric approach and how we help raise the bar when it comes to printing innovation. Imageworx and Cyngient’s advanced, problem-solving technology — in partnership with OEM press and finishing equipment manufacturers — is truly leading the industry.’

Through Cyngient’s partnership with Imageworx, the companies work closely together to develop products, leveraging Imageworx’s demo and preparation center in Levittown, Pennsylvania, just outside of Philadelphia.

Imageworx will feature its prototyping capabilities at Labelexpo Americas. With its knowledge of pre-press and print technologies, coupled with its equipment, Imageworx can produce label and shrink sleeve prototypes and production samples that can accurately be reproduced by a client's end printer.

Jeff Toepfer, president of Imageworx, explained: ‘Our advanced capabilities allow clients to produce production quality prototypes that will seamlessly transition to the printing process of their choice. This includes art creation, pre-press, flexographic printing, screen printing, digital proofing, color matching, cold foil, hot stamping, embossing, front and back side printing, shrink finishing, along with semi and rotary die-cutting, all available on a wide range of materials. Label and packaging printers are encouraged to stop by the booth, as demonstration samples are available for inspection throughout show.’

Daco Solutions

Booth 934

Daco Solutions, along with its agent Flexo Export, exhibits a Daco PLD-430M semi-automatic turret rewinder. The machine features a web with of 17in, a 40in unwind with roll lift, a laminating station, two die-cut to register rotary die stations, auto-set slitting, and a three spindle semi-automatic turret rewinder with roll closure.

Dantex Group

Booth 6129

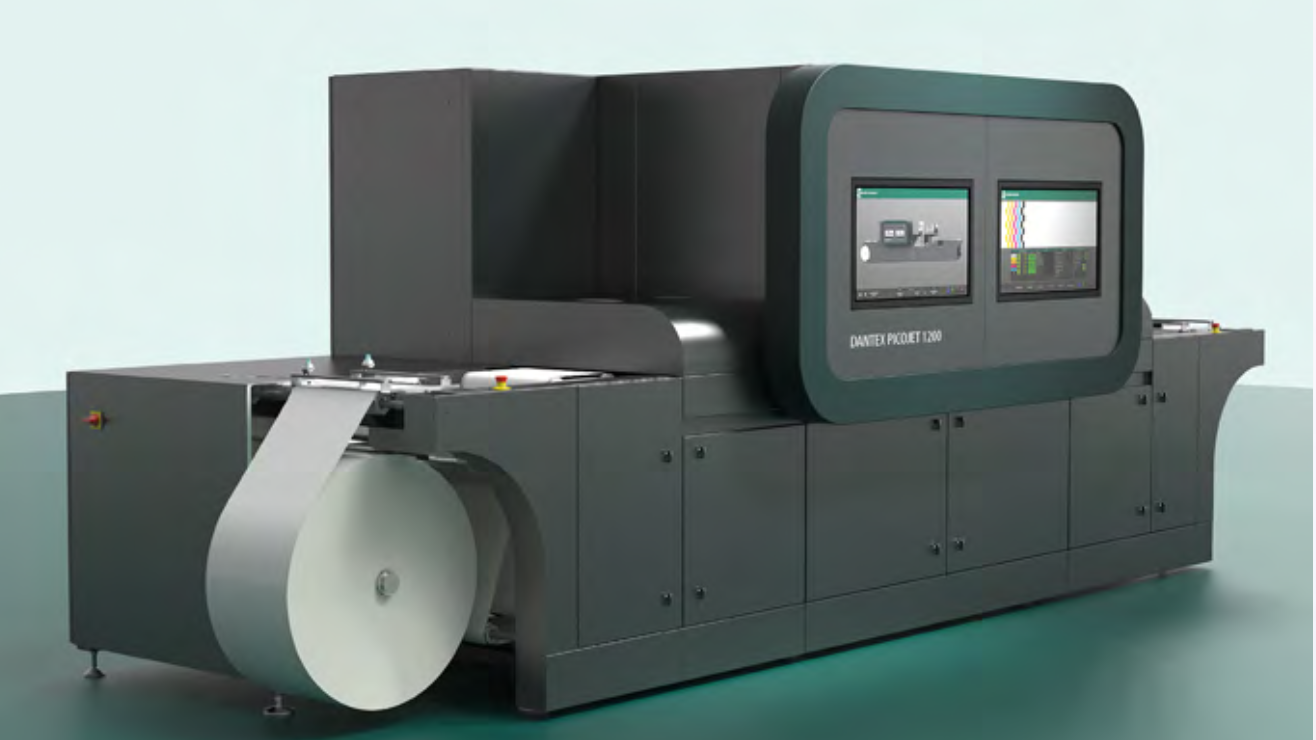

Dantex Group presents its PicoJet 1200 digital inkjet technology. PicoJet models are available as either reel-to-reel or as a hybrid press with in-line finishing capabilities, including flexo, die-cut, cold foil, lamination, edge trim, back scoring and rotary or shear slitting.

The Dantex team is on hand to promote the extensive range of plate processing and cleaning equipment, letterpress and flexo plate materials along with tapes and sleeves.

Darui (Ningbo Darui Automation Equipment)

Booth 6045

Darui showcases its range of digital label technologies, including digital printers, digital die-cutters, and laser die-cutters.

Decosystems

Booth 3540

Decosystems showcases Sentinel, an inspection technology developed for the label industry in different versions: silver, palladium, gold and platinum. Sentinel includes 100 percent print inspection control, color control, 2D and 3D code reading and grading and variable data verification. The optional Sentinel Workflow enables linking the printing machine and rewinder flow to save waste and keep the production under control.

The company also demonstrates its ScanDiff2 proof software matching and discovering all pre-press problems early in the work cycle.

On show is also the MultiLabel machine developed for pharmaceutical labels and equipped with automatic tension control, label/meter/diameter counter and Sentinel print inspection system.

Lastly, DECO_GPR (Global Production Report) also promoted at the stand is a software that keeps all production data accessible from a computer or smart device.

Delta ModTech

Booth 5415

Delta ModTech runs two RFID tag insertion demonstrations. The first, presented as part the RFID Experience, and the second is at its booth. Both processes feature Delta ModTech’s patented Island Transfer module and the Delta Crusader platform and RFID tags inserted on pre-printed, die-cut labels.

Delta’s Island Transfer process can provide a low-risk technology for introducing RFID tags and antennas in label production.

Digimarc

Booth 5702

Digimarc promotes its digital watermarking technologies already have been deployed at scale for the identification and the authentication of physical and digital items, including a notable example the partnership with a consortium of the world’s central banks.

Digital Print

Booth 6511

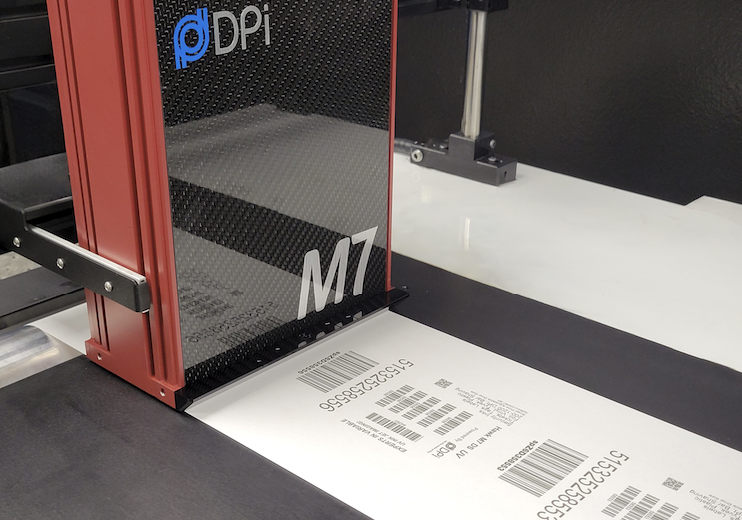

Digital Print introduces the M7, a 13in variable system operating at speeds over 800 feet a minute with a resolution of up to 600 DPI, printing variable barcodes, text and graphics.

The M7 is designed for efficiency and precision, optimizing ink usage and minimizing downtime.

The M7 13in system offers user-friendly operation and maintenance. The system can print widths of over 26in and be configured to print duplex jobs. It also comes in a double-bar configuration that can run twice the speed and resolution of a standard single-bar system.

Dilli

Booth 5929

Dilli unveils Neo Picasso Plus, a digital UV inkjet label press capable of printing at 600 x 1,200 DPI with width of up to 330mm. It is capable of full-color variable data printing and offers integrated UV LED curing system.

At the company’s booth, Neo Picasso Plus is equipped with an optional jumbo winder module for handling larger roll diameters to produce extended print runs and high-volume jobs.

Dienes

Booth 1308

Dienes Corporation showcases the new Pick & Place automatic positioning system for score cut applications. The new positioning system has been developed as a market-entry product for accurate and fast positioning of score-cut knife holders. It can be designed as a retrofit product or integrated into newly designed processing lines.

Dipco

Booth 1201

Dipco celebrates its 40th anniversary by showcasing Quick Change ink pan liners and catch trays to all segments of flexo, flexible packaging and digital print.

The company highlights ink pan liner technology advances for the latest generation of narrow web in-line and hybrid presses. The company expands its portfolio for digital finishing with open-fountain pan liners for CEI, GM, ABG, and Mark Andy coating stations. Products on display also include catch tray liners for flexible packaging and laminating operations.

DMS

Booth 950

DMS presents its latest innovations in hot stamping and foil-saving technology, including the FV-Series Hot Stamping System. The company also showcases its foil handling technologies, auxiliary UW/RW unit and a turn bar unit equipped with air bars.

Domino

Booth 5821

Domino demonstrates the N730i offering 1,200 DPI Bitstar printhead technology and print speeds of up to 230 fpm (70m/min). It is configurable up to seven colors (CMYKOVW) and covering 92 percent of the Pantone range and prints white at 76 percent opacity at speed. The optional pre-digital flexo priming station can optimize print quality on difficult media types; the optional post-digital flexo station can be used for varnishing, brand spot color or flood white for shrink sleeve applications.

The company also showcases the N610i, a 600 DPI machine available in up to seven colors (CMYKOVW) with 72 percent white opacity, able to print from 164ft/min (50m/min) to 230 ft/min (70m/min) offering a Pantone range of 92 percent.

Finally, the company launches the new Domino K300, which offers print speeds of up to 410 fpm (125m/min) at 600 DPI, or 820 fpm (250m/min) at 300 DPI. The K300 is suitable for VDP unique codes, 2D, or QR codes that require a print width of 2.1in (54.1mm) with one print station, or 4.26in (108.2mm) with two print stations.

Domino K600i and K300 are integrated on a Mark Andy Pro Series flexo press. Lake Image Systems, a Domino Group Company, vision inspection systems are shown at all Domino digital printing stations.

Dongguan Bengraphic Printing Equipment

Booth 5736

Bengraphic promotes two flexo presses: the IP, developed as an entry-level label converting equipment, and the F8, which can process film and folding carton paper with a maximum printing width of 650mm.

Double E Group

Booth 1341

Double E Group features a wide array of products engineered to boost the safety and efficiency of labeling operations. The company showcases its popular differential air shafts, cantilever strip and leaf shafts, as well as small diameter shafts. Double E also launches a new core cutter offering enhanced flexibility and economy.

Double H Plastics

Booth 947

Double H showcases plastic cores for the paper and label converting industry. These cores provide crush resistance, minimize dust contamination, resist moisture, and withstand tough operational requirements.

D.P.R. Labeling

Booth 5922

D.P.R. Labeling showcases Taurus system, a laser cutting and laminating machine eliminating the need for pre-die cut labels and die tools. It offers high-speed digital cutting, waste removal and a cutting management software.

The Aries system, also on show at the booth, is a semi-rotary label finishing machine that combines laminating, die-cutting, waste removal, slitting and rewinding in a single pass. It features a touchscreen PC interface and a flexible magnetic die plate.

The UV Varnish Module, compatible with Taurus and Aries, adds a protective layer to labels, enhancing durability against UV rays, moisture, and abrasion.

DuPont

Booth 1329

DuPont has been gearing up to feature next-generation portfolios at Labelexpo Americas. The company focuses on innovation, sustainability, performance and quality.

Cyrel Flexographic Solutions displays the DuPont Cyrel Fast 1000 TD solvent-free flexographic plate processor designed to offer productivity, quality and lower environmental footprint. It features a compact footprint, high productivity and improved user interface.

Cyrel also features the Esko XPS Crystal exposure unit, which utilizes the latest UV LED technology to maximize the consistent, high-quality performance of the Cyrel flexographic plates.

Additionally, attendees can experience Cyrel University, an online, on-demand training platform designed to reduce errors in the plate-room. The courses are entirely digital and allow users to get up to speed, accelerating their learning process.

‘I am thrilled to join Cyrel Flexographic Solutions as we participate in Labelexpo Americas 2024, one of the biggest events in the label and package printing industry,’ said Nolan Dzielak, North America commercial leader at Cyrel Flexographic Solutions. ‘We look forward to showcasing our latest solutions that cater to the tag and label and mid-web flexible packaging markets, and Cyrel University, our unique, online training platform for new hires and industry veterans alike.’

From the DuPont Tyvek side, in addition to showcasing the Tyvek material, visitors can experience the wide range of applications for Tyvek-based tags and labels. The company promotes its strength and resistance to water, chemical and tearing, as well as its ability to withstand extreme temperatures and environment conditions.

Durico

Booth 1515

Durico showcases a wide range of direct thermal film, including Phenol-free options that are safer for human health but also have lower environmental impact. Durico’s DT film products are designed to be highly resistant to harsh environments, such as exposure to heat, humidity, hot water, solvent, alcohol, oil and tallow.

The company also features its Translucent DT film that boasts enhanced transparency with a frosted look for see-through food labels.

Also presented are durable Inkjet PP films BS5609 and GHS compliant, and Inkjet DuPont Tyvek suitable for use with color inkjet printing systems.

Durst Group

Booth 3123

Durst North America showcases KJet, a new hybrid press making its American debut, alongside Durst Tau RSCi, and Durst’s software.

KJet combines Omet's dual servo flexo printing units with Durst's RSCi inkjet technology. Modules for finishing and further processing, such as cold foil stamping or die-cutting units, can be integrated into the KJet, offering flexibility and a broad application portfolio.

The company also runs demonstrations of the Durst Tau RSCi, designed for an industrial level of productivity. Available in printing widths of 330, 420 or 510mm, the press offers printing speeds up to 100m/min and can be equipped with the double white feature.

Durst Software & Solutions round out the booth lineup showcasing the software ecosystem ranging from web shops and online graphic editors to comprehensive workflow and analytics and ERP/MIS systems.

‘We are at the next evolution of the label industry,’ commented Steve Lynn, director of labels and packaging at Durst North America. ‘Durst has always been on the revolutionary side of the industry, leading the way through innovation and advanced solutions. We are shaping the future with the technology we are showing here at Labelexpo. We have paired the fastest printers, offering the highest quality and productivity on the market, with next-level intelligence technology, and we really look forward to sharing that with everyone at Labelexpo.’

Eaglewood

Booth 945

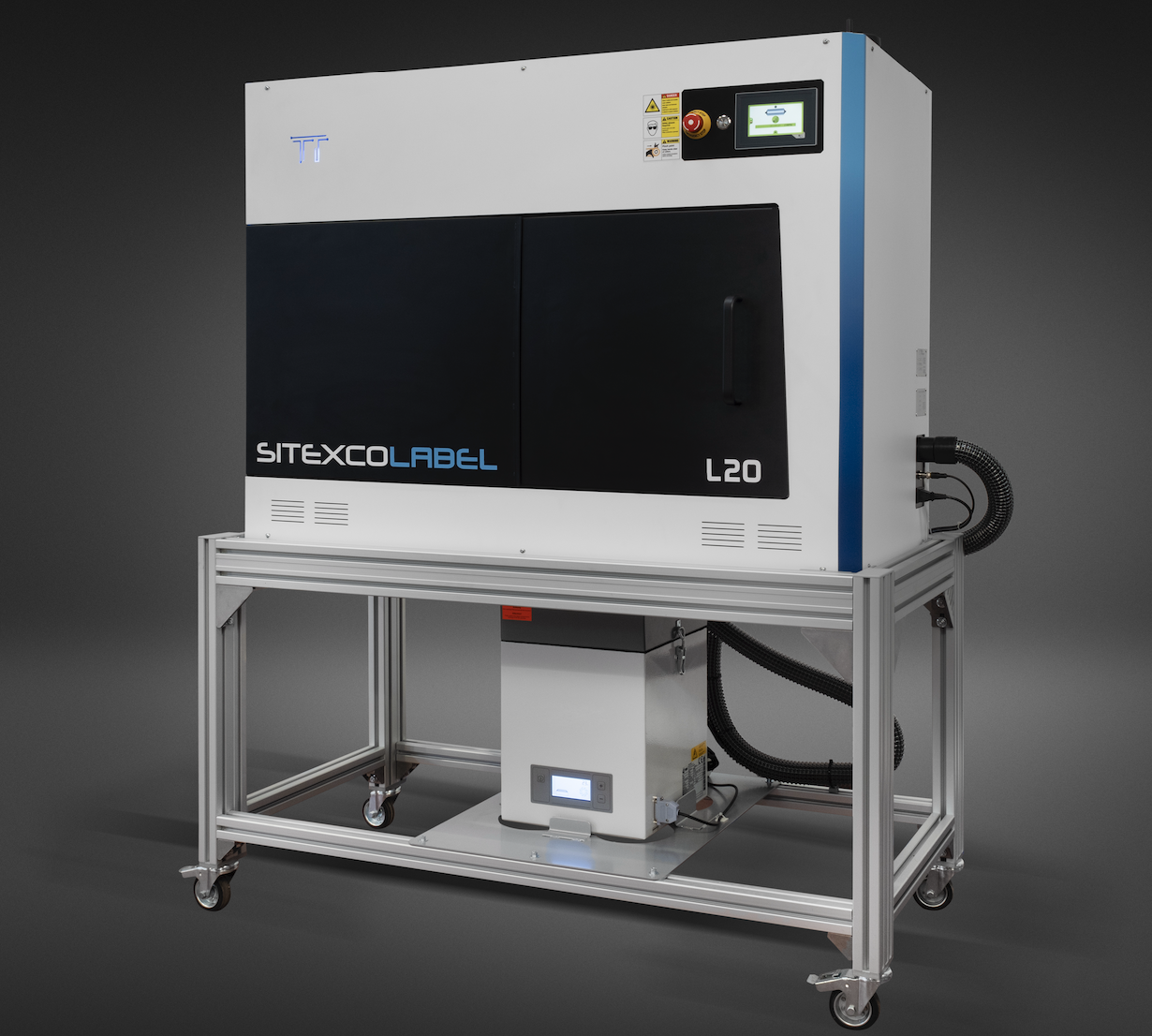

Eaglewood Technologies introduces the latest narrow web technologies for anilox roll and parts cleaning, including the Sitexco L20 anilox cleaner. Based on the award-winning Sitexco laser technology, it is designed for the label printers and produces cleaned aniloxes without water, chemicals, media or consumables.

The Nanovis Bella, also promoted at the show, provides a cleaning for HP Indigo parts with the Bella DC-1300 model able to automatically wash the BIDs on HP Indigo assets without consumables and VOC's.

Edale

Booth 5803

Edale exhibits alongside Canon USA. One of the highlights of the Edale range is the FL5 single-pass carton production line, offering multiple in-line embellishments and traditional flatbed finishing alongside high levels of process automation.Another standout product is Edale’s FL3 flexographic label press, engineered with automation designed to reduce waste and minimize the need for highly skilled operators. It offers high productivity and a customizable setup for premium-quality label production.

Darren Pickford, sales director at Edale, commented: ‘We're thrilled to be invited to Labelexpo Americas 2024 alongside Canon USA, where the theme for this year’s event is “Spring into Action” with a pinball motif. It's fitting, as we know many packaging and label converters feel like they're pinballing around the press market, trying to find the perfect solution.

‘As “The Carton and Label Press People”, we understand these companies' challenges and pressures. That's why we customize our world-class press technology. Our customers don’t adapt to our class-leading machines; we build them to suit our customers' specific needs. We're here to help converters stop the pinball effect and find their ideal press solution.’

Maggie Reed, US sales manager at Edale, added: ‘Labelexpo Americas is the perfect platform to meet with converters and illuminate how Edale's flexographic press solutions for label and carton production complement Canon's digital solutions. For example, our unique FL5 single-pass carton production line opens doors to the high-potential, sustainable carton market, providing new growth opportunities for businesses in the packaging industry.

‘For label makers seeking improved efficiencies and consistent print quality, our FL3’s high productivity and customizable setup make it the perfect solution for efficient and high-end label production. On the booth, we’ll be booking demos of the latest Edale technology, certainly not to be missed. We're excited to engage with expo visitors to share how our flexo-focused technology can help converters ‘spring into action’ and capture new market segments.’

Elkem

Booth 1029

Elkem Silicones showcases its Silcolease, a range of release coatings for nonstick, inert and heat-resistant release liners for papers and film coatings. They offer unique properties utilizing silicone polymer technology and custom additives. These fluid systems allow easy coating and excellent spreading performance and are rapidly transformed into ‘dry-cured’ surfaces via heat or UV light-curing processes.

eProductivity Software

booth 1417

eProductivity Software (ePS) showcases the rearchitected Radius ERP and ePS Packaging Suite, featuring intuitive workflows, advanced integrations and automation with leading technology partners like HP Indigo PrintOS and Esko Automation Engine.

Key highlights include full digital workflow automation and real-time visibility and traceability for packaging converters, resulting in increased revenue and profits.

Visitors can experience how ePS’ products can transform packaging operations, improve traceability, reduce costs and increase profitability.

EMT International

Booth 136

EMT International presents Rotocontrol portfolio of finishing machines in inspection and rewinding configurations, which can be fitted with numerous modules such as integrated vision inspection, semi-automatic turrets, multiple slitting, counting and product detection technologies.

The BL-Series on show is equipped with the Longford International OS700X triple motor surge feeder or a Kraus Joker booklet feeder.

The company also promotes the Rotocontrol DT 2.0 modular hybrid digital finishing line, compatible with all major digital printing presses. It integrates flexo and inkjet printing, die-cutting unit, inspection, register control and offers a range of options for the processing and finishing of digitally preprinted rolls.

Also featured is EMT International’s Chameleon web finishing technology and auxiliary processing products for the inkjet market.

ETI Converting Equipment

Booth 817

The company runs live demonstrations of its flagship Cohesio narrow-web converting, printing and coating equipment, showcasing its flexo printing, silicone coating, adhesive coating/laminating and die-cutting capabilities. Attendees can see the transformation from raw materials to finished labels in real-time. ETI also demonstrates how vertically integrating silicone and adhesive coating can create various labels from start to finish, catering to all end-use segments.

ETI also partnered with Martin Automatic and Lemu Group to showcase integration of Martin Automatic’s MBS butt splicers for nonstop web automation, Lemu Group’s GTU turret rewinder and UltraCompact end-of-line automation equipment with Cohesio machine. This collaboration highlights how these technologies provide unique customization options.

EyeC

Booth 1535

The Chicago-based company showcases its range of technologies and latest developments with live demonstrations, focusing on the new EyeC ProofRunner options for AI-based defect classification and the improved EyeC Proofiler DT series.

EyeC also promotes its new in-line inspection system The ProofRunner Highlight using the partnership we have with Prati to demonstrate the speed and capabilities of the ProofRunner as well as the abilities of the rewinder.

Two more ProofRunners can be seen in the Rotoflex and Vemax booths. This in-line inspection system guarantees fast and precise 100 percent print inspection for labels and flexible packaging with web widths of up to 1,700 mm.

Brand new options for the entire EyeC ProofRunner, presented for the first time, demonstrate the power of AI-based defect classification. Thanks to precise defect classification based on the image content, relevant defects can be identified more clearly and brought to the operator's attention.

Another highlight at the booth is the improved EyeC Proofiler DT series. In addition to technical improvements for optimized speed, handling, and ease of maintenance, the scanner-based inspection.

Excelitas Technologies

Booth 3810

Excelitas promotes a wide range of UV LED curing products designed to address the most demanding needs of printers and converters in label and packaging applications.

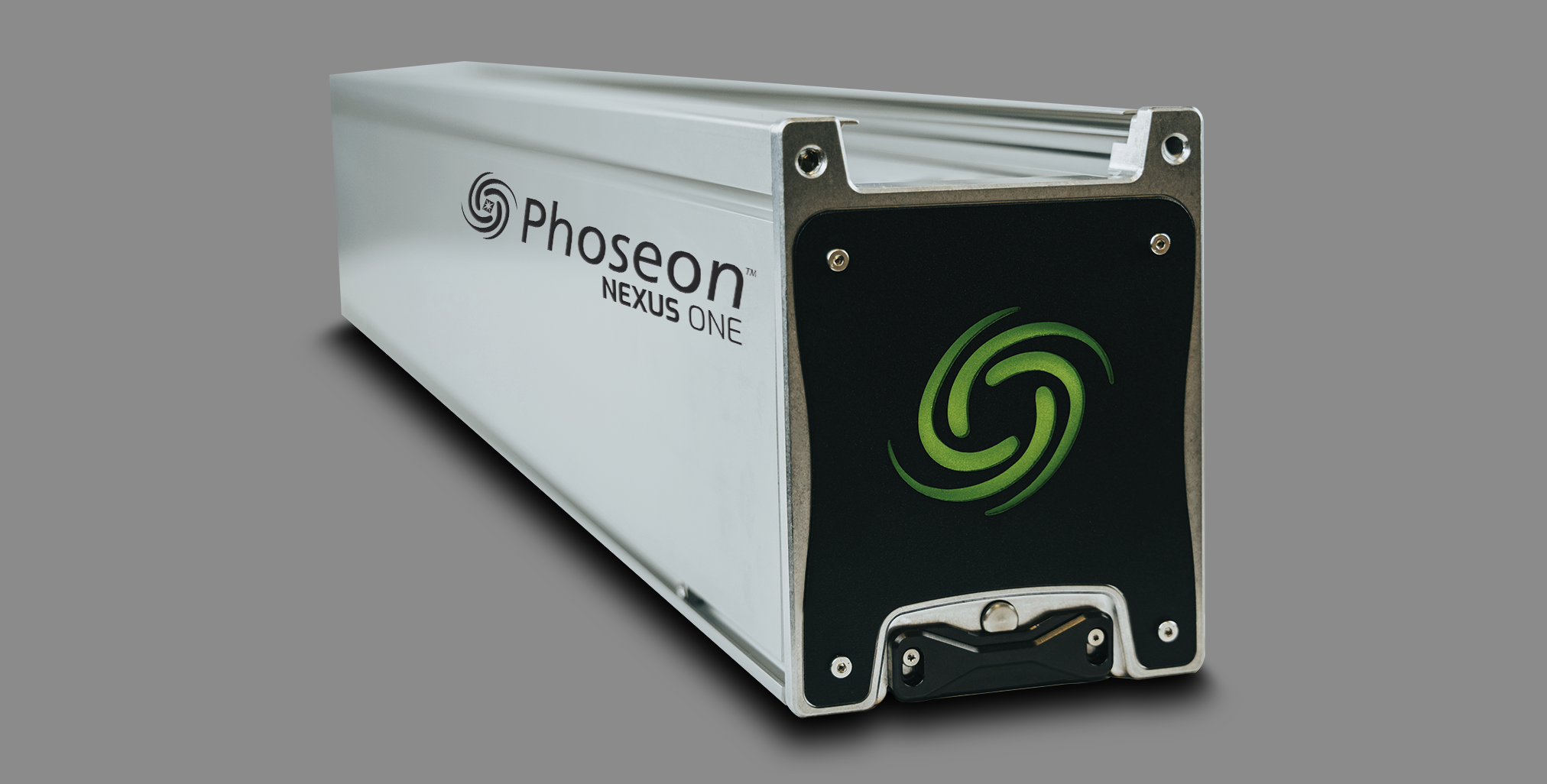

The booth showcase will include Phoseon Nexus One UV LED curing systems with an expanded UV LED curing platform for flexographic printing, the Nexus One water-cooled products are now available in six sizes: 300mm, 375mm, 450mm, 525mm, 600mm and 675mm.

According to the company, the new systems deliver 38 percent more energy with 90 Watts per 25mm LED array segment.

To complement the water-cooled systems, Nexus ONE air-cooled products are available in the same sizes up to 600mm.

With high-power LEDs and advanced patented technology, these products deliver high energy density and fast, uniform curing in labels and packaging applications. Nexus One also features real-time remote monitoring capabilities for Industry 4.0.

The company also promotes the Phoseon FireJet air-cooled system, which is aimed primarily at UV inkjet wide-format systems. It can cure small, medium, and grand-format digital printing systems at the highest speeds. It is suitable for many large single-pass UV inkjet and wood coating applications.

Also on show is Phoseon FireLine water-cooled system designed for various web/conveyor-based UV curing applications. Its architecture is engineered to make the systems scalable and built up to 2 meters long.

Fangda Packaging

Booth 755

Fangda promotes its range of adhesives, functional coating, lamination, slitting and converting of packaging supplies.

Fedrigoni Self-Adhesives

Booth 3101

Fedrigoni Self-Adhesives showcases a variety of products for the wine and spirits label converters, including a premium black paper range, materials with recycled content and 100 percent recycled materials and labelstock made from alternative fibers.

Home and personal care label printers can see a selection of films from Fedrigoni’s patented open-close technology for wet wipes.

Lastly, in the food and beverage section of the booth, the company showcases Ri-Move, an APR-certified wash-off material, as well as compostable materials.

In the Smart Labeling section, the team is promoting a portfolio of RFID inlays and tags from Tageos.

Fedrigoni Self-Adhesives (FSA)

Booth 3101

The company showcases an expanded North American portfolio across four core categories: wine and spirits, food and beverage, home and personal care and pharmaceuticals. Catering to diverse applications, FSA offers materials for food and beverage segment that adhere to a variety of substrates, including challenging ones. FSA provides products utilizing polypropylene, polyethylene, polyester films and coated paper. For home and personal care, FSA provides a broad array of face materials and adhesives tailored to nearly every application. The company’s expertise enables it to recommend the best material combinations for labeling containers, packaging, and open-and-close needs, ensuring optimal performance and aesthetics. For pharmaceuticals segment, FSA delivers products for applications ranging from small-diameter and OTC containers to hanging labels, cryogenic labels, multilayer constructions, and booklets. Its materials meet stringent certifications and operating procedures to withstand demanding conditions and assure patient safety.

First Crown Enterprises Holdings

Booth 3721

Crownflex showcases its plate-making equipment, printing equipment and printing consumables, including the new High-Quality Flat Top Dot Dry flexographic platemaking system, digital thermal flexographic plates, ultra photon exposure machine, dry cleaning flexographic and UDI ultra-high-accuracy digital laser imager.

Flexcon Company

Booth 1311

Flexcon features products enabling recycling, reducing waste, including removable, conformable, and post-consumer waste labels.

Flexcon’s sustainability expert Dan Riendeau shares insights on what drives consumer demand for sustainability and actionable steps brands and converters can take to become more profitable and sustainable on the Innovation Stage on the first day of the show.

Flexo Wash

Booth 511

Flexo Wash demonstrates a wide range of its cleaning technologies and offers a special discount for booth visitors. Attendees can witness the power of Flexo Wash's Plate Washer and LaserX Anilox Cleaning Machine in action. Demonstrations are held at various times throughout each day of the expo.

The company also offers an exclusive discount on all Flexo Wash cleaning systems for Labelexpo attendees. This limited-time offer allows industry professionals to make strategic capital investments.

‘As part of our commitment to innovation and efficiency, we’re offering this special discount to help our customers invest in the latest technology that will enhance their productivity and performance,’ said Patrick Potter, president of Flexo Wash.

In addition to live demonstrations, Flexo Wash experts will be available for one-on-one meetings to discuss the company's latest plate and anilox cleaning solutions advancements.

Flint Group

Booth 6419

Flint Group presents its products designed to minimize energy use, reduce waste and support packaging circularity. The range available at the booth includes Evolution de-inking primer and caustic-resistant Overprint Varnish (OPV), which enhance sustainability in packaging by improving material yield during the PET bottle recycling process.

The company also promotes the dual-curing EkoCure ink series, which eases the transition from UV mercury to UV LED curing and Ultra Clear Dual Cure Coatings, which can cure under UV LED lamps and UV lamps containing mercury.

Anna Niewiadomska, marketing manager at Flint Group, said: ‘Labelexpo Americas is a must-attend event for anyone involved in the label printing sector. With the need for efficiency in printing becoming clearer every year, we are pleased to highlight our solutions designed to help converters simplify their operations. Importantly, we are excited to share details about our latest innovations addressing sustainability, recycling, and regulatory concerns.’

Flora (Shenzhen Runtianzhi Digital Equipment Co)

Booth 5699

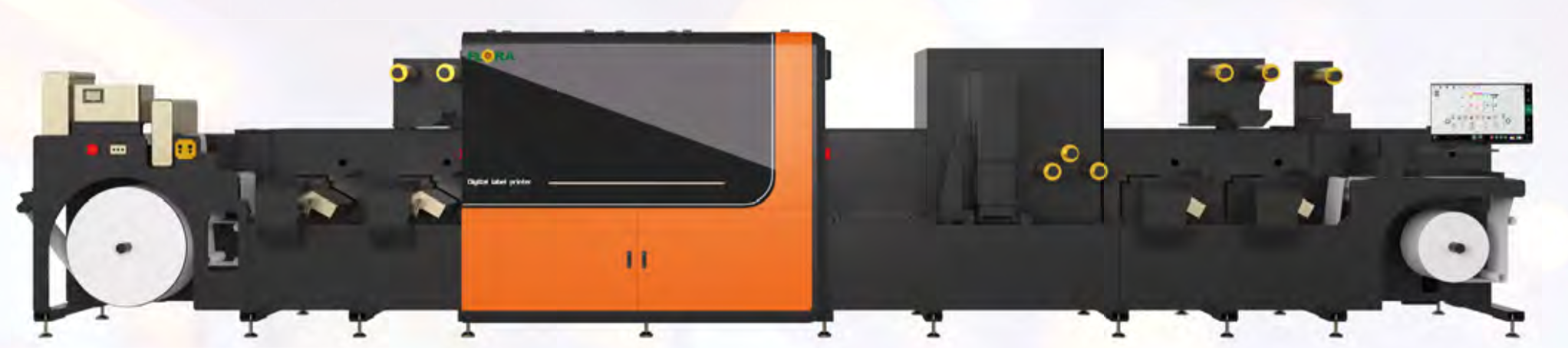

Shenzhen Runtianzhi Digital Equipment Co launches the Flora J-350 P8 HD UV inkjet label press. It prints at a resolution of up to 1,200x1,200 DPI at speeds of up to 100m/min (328ft/min), supporting a CMYK+W+O/V color configuration and media range is between 0.04-0.35mm on coated paper, synthetic paper or films.

The Flora J-350 P8 HD is equipped with a closed-loop tension control system, web cleaner and corona treater and has a maximum roll capacity up to 1,000mm.

The press can be optionally configured with flexo, cold foil, varnishing and laminating modules.

The J-350 P8 HD boasts a compact design, covering an area of only about 14sqm.

Fujifilm

Booth 3623

Fujifilm Flexographic Packaging showcases sustainable technologies and its efforts toward more efficient product design for both analog and digital to lower CO2 carbon emissions.

Fujifilm’s products for the packaging industry deliver sustainable and responsible manufactured goods without compromising quality. To demonstrate these efforts, Fujifilm recently launched its new award-winning J Press FP790 water-based inkjet digital flexible packaging press.

Fujifilm Integrated Inkjet Solutions presents the 46kUV Printbar System UV printbar for label imprinting adding variable data capabilities, including high-quality text and codes, at speeds up to 500 feet a minute (152m/min) at 1,200 x 600 DPI.

The 46kUV features the Samba printhead and is available in 13-, 17-, and 20-in print widths.

Another product on show is the DE1024 digital embellishment system able to add gloss or tactile effects to existing analog or digital print production.

General Inkjet Technology

Booth 5621

The company presents its recently launched Label Modular 330HD with 1,200 x 1,200 DPI printhead for label printing with up to 9-color channels and printing speed of up to 70m/min. Its modular design allows for several optional equipment configurations including coating, printing, varnishing, foil-stamping and cold-stamping.

GEW

Booth 3500 and 3608

GEW launches two new high-performance LED products.

The new AeroLED2 delivers an increased power level, when compared to the original AeroLED model, for faster printing across more applications. It is also now available for wider web widths, to cater for more presses in the narrow web market. It can be interchanged with GEW’s Arc lamp systems and maintains the centralized fan cooling architecture.

The second new product, LeoLED2, introduces two power level options to the water-cooled system. The regular power option offers modest gains over the original LeoLED while maintaining backward compatibility, while the high-power option, delivers significant increases in UV irradiance and dose over its predecessor for extreme curing challenges in the packaging market.

Ghangzhou Super Color

Booth 5618

The company promotes its UV flexo inks, including products for self-adhesive labels, shrink sleeves and tubes, low-migration inks, low-halogen inks and lightfast inks. On show are also UV varnishes, primers and adhesives.

GIC Online

Booth 3709

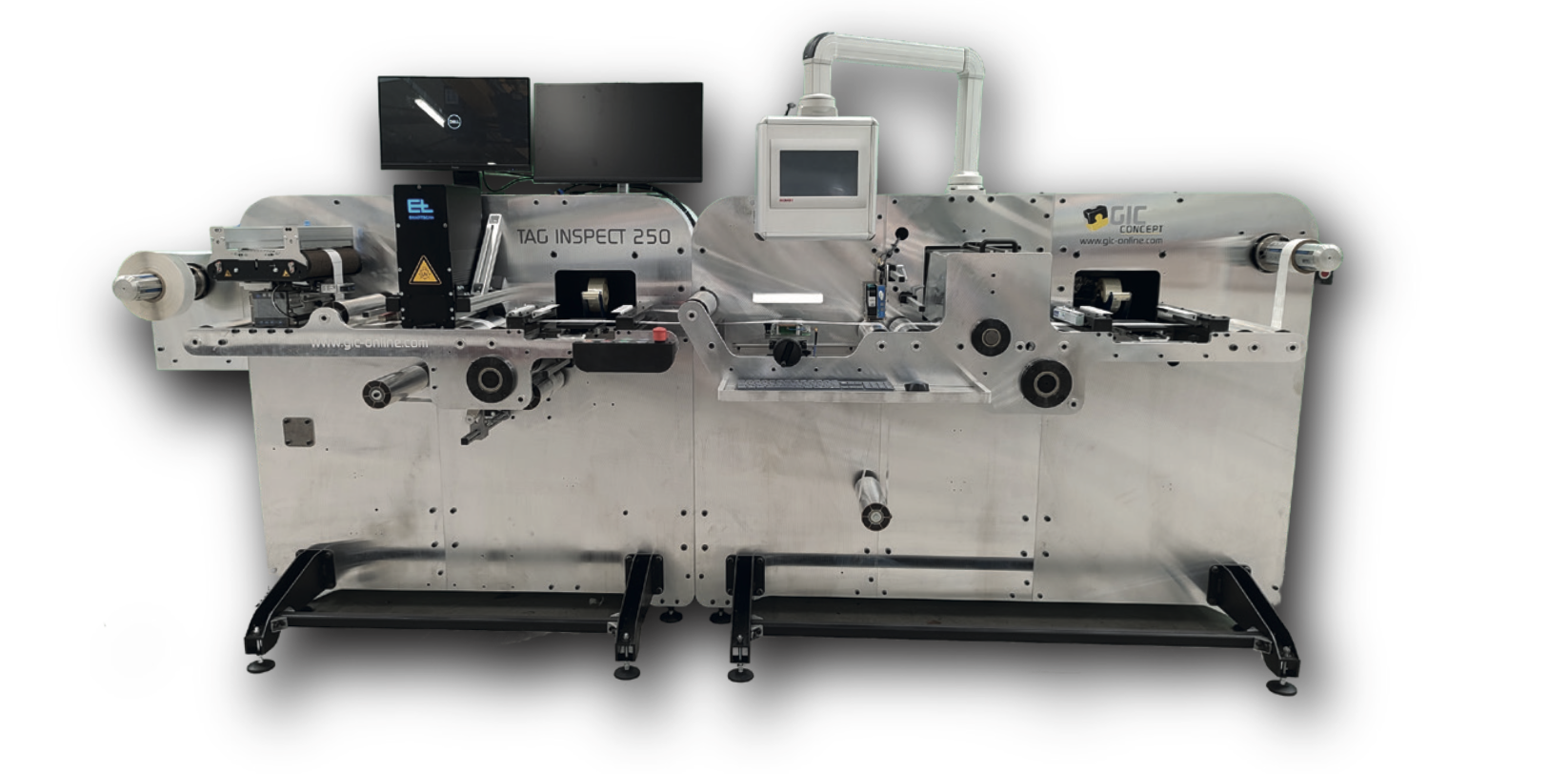

GIC Online features converting lines for RFID and adhesive labels. Taginnov range supports the RFID tag manufacturing process. GIC provides tailor made products that adapt to the type of inlay of the customer (mono or multi lane integration) and offers productivity and control in line with one step to produce RFID tags.

The Tag insect 250 controls the inlay in the integrality, position of the inlay inside the label, frequency test, encoding a roll of label with 100 percent control. Taginnov Speed Etiq can integrate wet RFID inside a label.

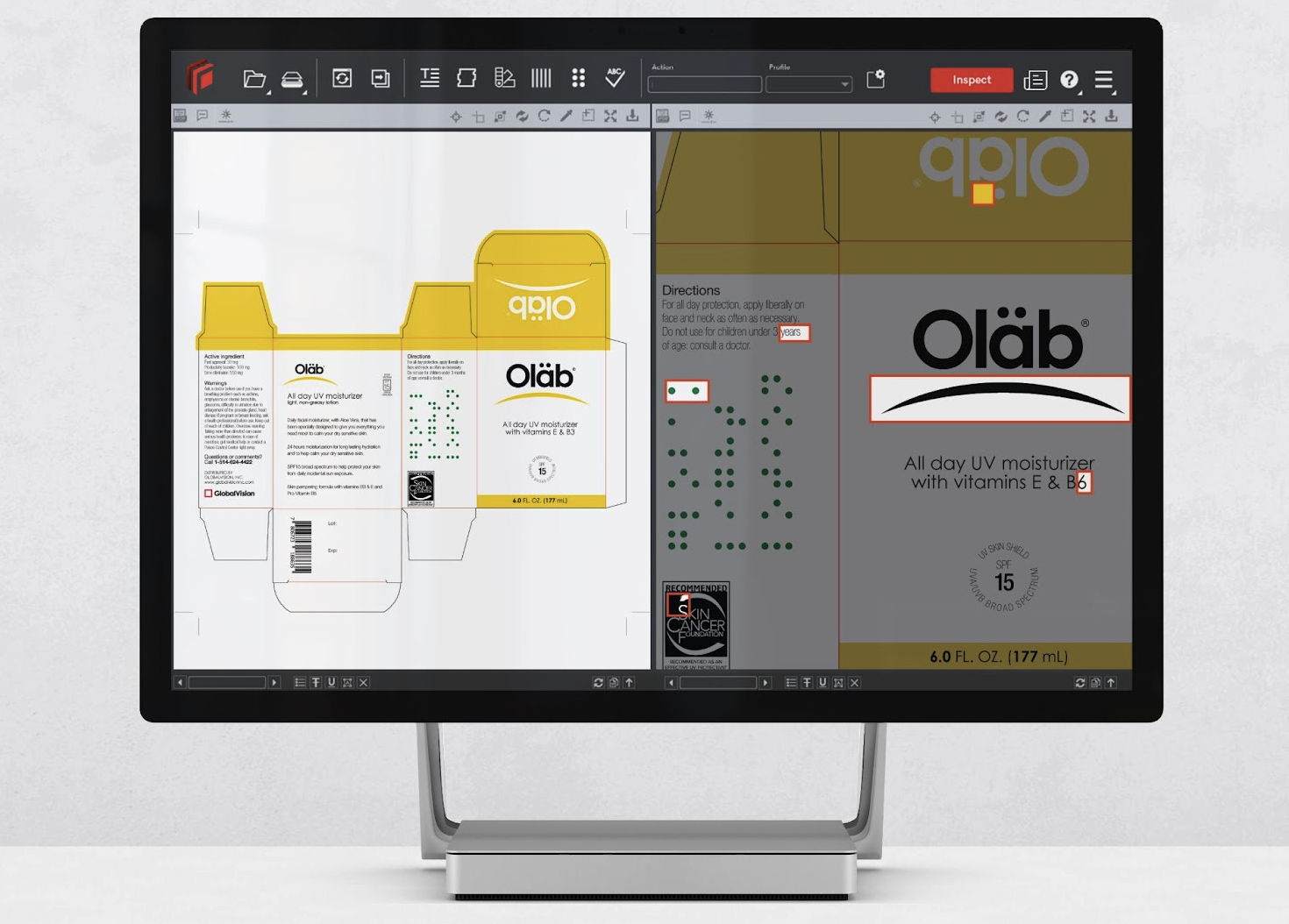

Global Vision

Booth 1621

GlobalVision features its products and services for proofreading, quality assurance and requirements for regulated industries with capabilities including braille height inspection, print inspection, text inspection, barcode inspection, Cloud PDF and Proof inspection, large-format scanners for full press sheet inspection, and counting systems for inserts, cartons, and vials.

GMerix

Booth 3542

The company showcases its services and products beyond standard coating, offering a unique blend of expertise, innovation and customer-focused collaboration for pilot projects, short-runs and high-volume productions. GMerix specializes in manufacturing premium labelstock materials, providing innovation and material versatility.

GMG Color Americas (GMG)

Booth 359

Alongside the comprehensive GMG portfolio of products, such as the GMG ColorProof digital proofing system and GMG ColorServer, a fully automated tool for conversion to any output color space, Labelexpo Americas 2024 can see four key technologies in the spotlight.

ColorFarm, distributed by GMG, is a production cockpit for GMG technologies which streamlines processes, integrates preflighting, and centralizes information management between GMG software. With its easy job quoting and production control, ColorFarm adds cost-saving potential to industrial digital printing.

Also on show is the GMG ColorProof designed specifically for HP Indigo. It delivers predictability and cost-effective proofs, freeing up press capacity and enabling integration of proofing without disrupting press schedules.

The company also promotes Proofing Calculator Tool, which demonstrates cost savings possible with GMG ColorProof for HP Indigo; and GMG ColorPlugin for Adobe Illustrator, offering a vector conversion.

Kelly Gorra, marketing manager at GMG Color Americas, commented: ‘Every year, Labelexpo Americas brings together all corners of the label and package printing industry. It’s an opportunity to see the latest technologies in action, so it’s no surprise that GMG Color Americas has plenty to show. The global GMG Color business is celebrating its 40th anniversary this year, so we will demonstrate why our platforms are still, after all this time, the gold standard.

‘The pressure for fast and efficient printing has never been greater, so our customers are looking for every tool at their disposal. At booth #359, we’ll be demonstrating updates to some of our most popular color management and proofing platforms, as well as some exciting new additions to our lineup. Each one is designed around real day-to-day needs, helping printers drive maximum value in a market that demands nothing less than the best, every time.’

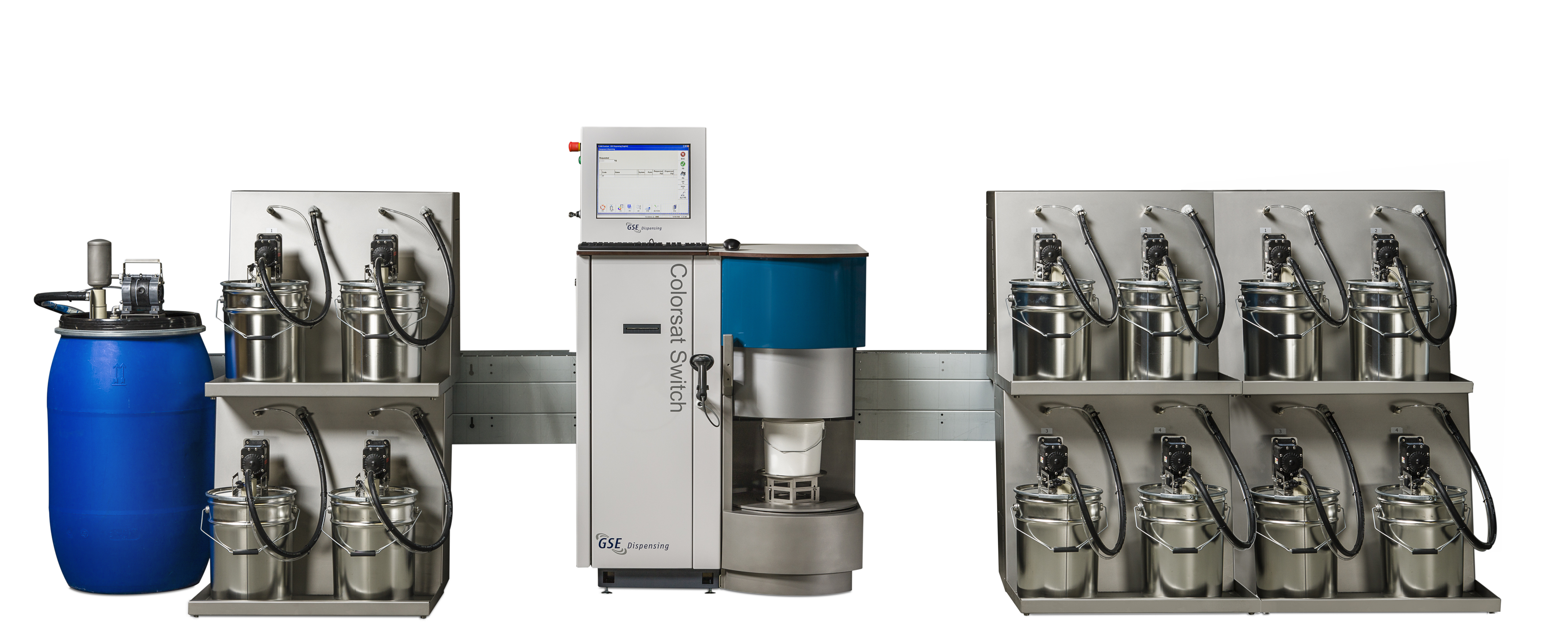

GSE Dispensing

Booth 751

GSE introduces the redesign of its software program, GSE Advanced reporting. The new version automatically sends reports from the dispensing machine, giving businesses deeper insights into ink consumption.

In the fourth quarter of 2024, GSE will introduce a service to upgrade its global installed base of Colorsat ink dispensing systems and Ink manager software to Windows 11. The initiative will ensure GSE’s customers benefit from the enhanced security and performance of the latest Windows operating system.

With Microsoft ending support for Windows 10 in 2025, this upgrade will protect GSE ink dispensing equipment and software from emerging cybersecurity threats, while optimizing system performance.

Maarten Hummelen, GSE marketing director, said: ‘Automating ink-related processes is vital for addressing the needs for quality assurance, sustainability, and adaptability in an increasingly complex package print supply chain. At Labelexpo Americas, we invite printers to explore how our integrated software and dispensing systems can streamline workflows and drive competitiveness in today's challenging business environment.’

GSE experts will be available at the booth of the company’s North American distributor, UPrint Technologies.

Graphimecc Group

Booth 5212

The company will showcase its expertise in automated machines for serialization, precision converting and mass encoding of RFID smart labels. It presents a new generation of entry-level converting and encoding products. The latest generation of Graphimecc systems uses patented technology that is now tailored for entry-level productivity requirements without sacrificing automation, usability and certified zero error production output.

Graphimecc RFID memory map editor (allowing RFID memory management by a standard machine operator), dual-technology RFID products (both UHF and NFC chip management in a single pass) and full networking capabilities make this new generation of systems a backbone of RFID converting and encoding.

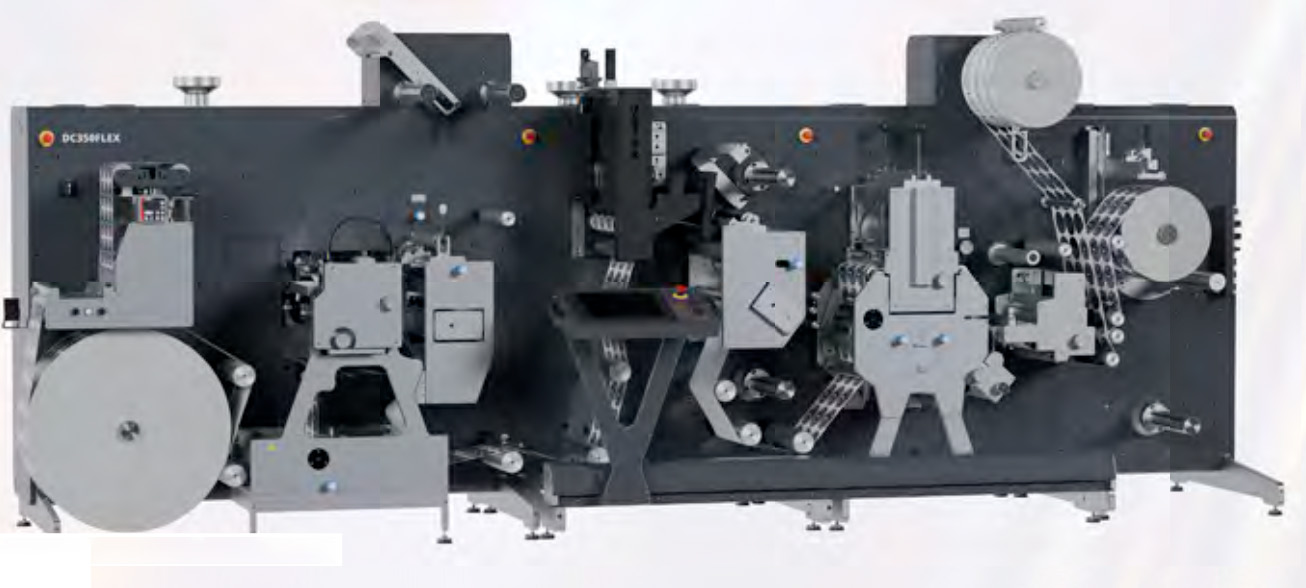

Grafisk Maskinfabrik (GM)

Booth 6111

GM showcases the DC350Flex+ Premium finishing line with high-speed die-cutting. It features semi-rotary varnishing, die-cutting and can be configured with a high-speed single anvil (HSSA). It runs at up to 80m/min (or 130m/min when fitted with full rotary die-cutting). The modular design allows converters to choose from multiple configurations, adding options such as digital embellishment, laser cutting, hot foil, and even integration with third-party technologies.

Visitors can also experience the GM DC350Mini compact and DC350Nano ultra-compact label finishers, as well as the HF350 Hot foil unit, the LC350 Laser finisher, the LR250+ Label rewinder, and the CC160/200 Core cutter.

CEO Uffe Nielsen, said: ‘Labelexpo remains the premier show for label and flexible packaging innovation, which is why GM can always be found right in the thick of it, sharing our finishing experience and expertise with converters aiming to accelerate opportunities. The 2024 Americas edition promises to be another excellent occasion for demonstrating our latest machines, including our flagship DC350Flex+ Premium line.’

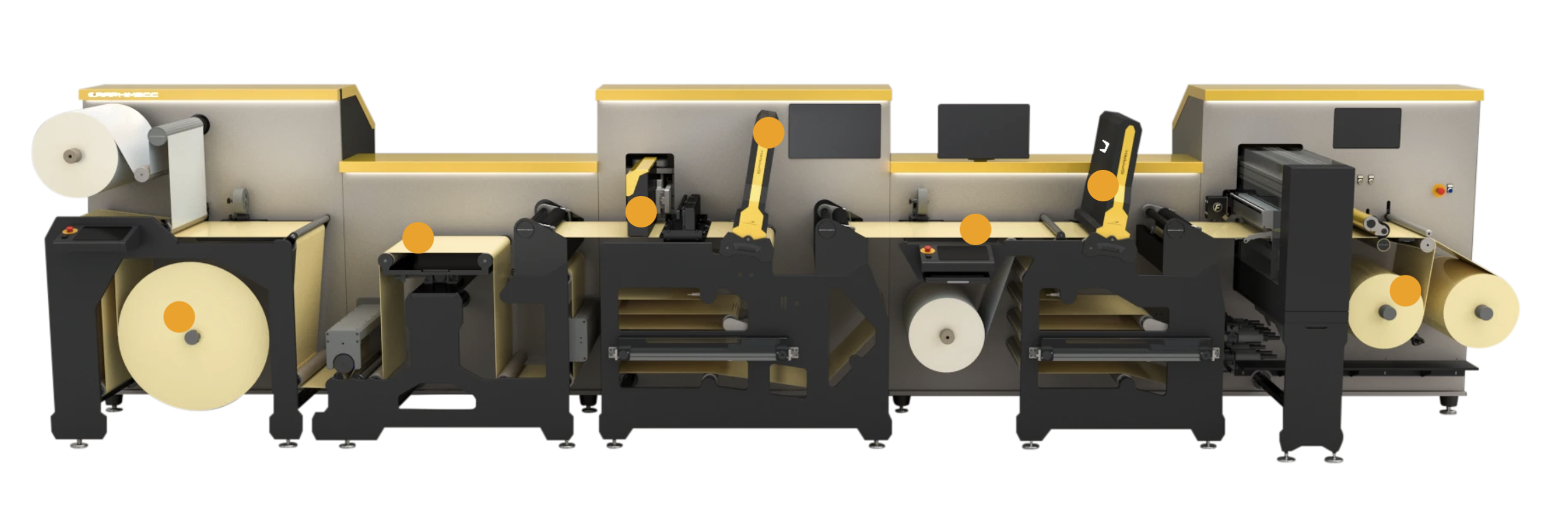

Grafotronic

Booth 911

Grafotronic showcases four machines, including its flagship DCL2 in two different configurations and two versions of the CF2, a compact machine that can be extended in the future.

The exhibition includes the CF2 in a HAPTIC configuration, equipped with a flatbed screen printing and a hot stamping module. The ultra-high stamping pressure can be controlled through the electronic pressure control allowing each corner of the counter pressure plate to be individually adjusted. The module extends dwell time and enables multi-stroke foiling and embossing, as well as single foil and complex multifoil designs.

Grafotronic also introduces Infinity, an automatic turret designed for producing a wide range of labels, including those printed on delicate, heat-sensitive substrates or using heat-sensitive ink. It features numerous automatic changeover capabilities, such as a glueless start for clean label separation from the core, roll closure with printed labels, automatic core positioning and finished roll ejection.

Additionally, Grafotronic presents the Boon-Tech suite of efficiency-enhancing auxiliary machines, including a slitter/rewinder, fan-folding equipment, core cutter and label cutter.

GTI Graphic Technology

Booth 5600

GTI presents its new D50 LED product portfolio, including desktop systems, floor stand models, large format viewing systems and press console viewing stations. The LED lamps used in these products have a CRI that is greater than 98, are environmentally friendly, offer compliance to ISO 3664:2009 for 7,500 hours of use, are EU RoHS compliant, require no warm-up time, and are available in lengths of 24in, 36in, 48in, and 60in.

GoDEX International

Booth 1620

GoDEX unveils its thermal printing technologies, which integrate with popular printer languages such as EZPL, GEPL, GZPL, GDPL and come with free label and tag design software that supports database integration. GoDEX’s showcase is headlined by the GX4600i, a 600 DPI thermal printer boasting a 5in video touchscreen LCD with built-in video-assisted guidance, as well as one-touch calibration button.

Gonderflex

Booth 6421,6886

Gonderflex showcases its GFXL 3000 finisher in the show’s dedicated FlexPack Factory area. The finisher is a versatile multi-process mid-web finishing platform for flexible packaging, shrink sleeve, labels and even folding carton. Live demonstrations show in-line thermal lamination, flexo printing and varnish, digital embellishment by JetFX, cold foil, cast and cure and slitting.

This machine is designed to combine all the processes required to finish rolls of digitally printed 30in wide web. Also, on display at the stand is the R330 digital finishing machine for labels with flexo printing and semi-rotary die cutting along a GFSRE-1300 compact label slitting machine.

GPPE Automation Group

Booth 1241

The manufacturer promotes roll converting and packaging products, including fully automatic thermal roll slitting, fully automatic self-adhesive slitting, flexographic, and digital printing machines. The company mainly serves thermal paper, POS, ATM, thermal stickers, logistics bills, labels and other printing, printing and slitting processing enterprises.

Guangzhou Xinzhu Adhesive Material

Booth 1400

The company promotes a diverse range of high-quality jumbo rolls, including paper labels, such as direct thermal ECO/TOP, semi-gloss, woodfree, and fluorescent paper. Also on show are film materials and inkjet materials.

Hangzou Todaytec Digital

Booth 1239

Todaytec shows several products, including the TDW136, enhanced wax ribbon with strong scratch resistance and high sensitivity. Also on show is the TDM209 general wax-resin ribbon with high printing performance, low printing temperature, high printing blackness, strong scratch resistance, and high-resolution printing.

As a cost-effective general wax-resin ribbon alternative the company promotes the TDM242, which can print well on various substrates at low printing temperatures. Besides its excellent scratch resistance and high blackness, it also offers small characters and fine-line printing.

Lastly the team discusses the benefits of the TDR345, high-performance cost-effective resin ribbon offering high printing blackness, media adaptability and alcohol resistance.

Harper Corporation

Booth 812

Harper introduces its new patent-pending Xtreme Channeled Application Technology (XCAT).

The XCAT engraving has a combination of consistent pocket structures that create a channel flow, acting like a closed cell channel without ink sag. It also makes the anilox easier to clean and can reduce or eliminate scoring by allowing particles to pass-through rather than being trapped behind the blade.

The XCAT has been designed to maintain the optimization in artwork running on traditional 60-degree engravings and is suitable for ink spitting, ghosting, scoring, foaming, ink re-solubility at high speeds, maintaining plate angles and speed.

HB Dynamics

Booth 3639

HB Dynamics focuses on coatings, including digital print primers, functional top coats and adhesives (both pressure sensitive and heat seal). Materials in its portfolio include polypropylene, polyethylene, polyester, polycarbonate, styrene, ABS, acrylic and PVC. Its lamination products include but are not limited to plastic films, fabrics, foils and adhesives.

HB Fuller

Booth 941

H.B. Fuller shows its microsphere PSA, Gel-Tac that enables the creation of ultra-removable and highly repositionable products. Gel-Tac utilizes water-based acrylic and pressure-sensitive microsphere technology for linerless self-wound label applications. The company also presents its Swift melt Earthic 9010E, a near-carbon-neutral hot melt adhesive made from a high percentage of fossil-free and sustainable raw materials. This versatile adhesive is ideal for labelstock applications and is ISCC+ certified, ensuring full supply chain transparency.

Heidelberg / Gallus

Booth 3523

Heidelberg and Gallus showcase an ecosystem of technologies designed to drive down the total cost of ownership, reduce reliance on skilled labor and future-proof businesses.

Gallus unveils the latest Gallus One 17in digital inkjet label press, featuring an extended color gamut at 230ft/min, and a brand-new ‘system to compose’. Gallus machines now boost adaptability, modularity and versatility with the ability to retrofit the existing equipment or modify it into new configurations by integrating the Labelmaster modules.

The booth visitors can also learn more about Prinect, the workflow streamlining digital production, and explore the latest advancements in the Screeny technology used to embellish and enhance labels.

Heidelberg is also showcasing material handling tools from its partner Dotec, including pneumatic roll handling systems and a range of products from Double E Group enhancing workplace safety and operational efficiency.

HMJ Tech

Booth 3706

HMJ Tech shows its automated ink dispenser A200. Developed as a compact and cost-effective machine it can improve ink room efficiencies. The company also displays its newly developed line of semi-automated and manual dispensing systems.

Henkel Adhesive Technologies

Booth 455

The manufacturer of adhesives, sealants and functional coatings highlights how it is instrumental in driving sustainability in the packaging industry. Henkel demonstrates how the manufacture of sustainable products can be put into practice with its portfolio of pressure-sensitive adhesives.

Henkel’s selection of hotmelt, water-based, UV and solvent-based acrylic adhesives offer high-quality bonding for PSA tapes, labels, and graphics that are compliant with TLMI test protocol RCA LRP-2 for post-consumer recycling processes.

Two label adhesives, Technomelt 4144 RE and PS 9625 RE, are among the featured products. These are part of the RE range, which encompasses adhesives and coatings designed for recycling.

Technomelt 4144 RE is used for general-purpose labels and tapes. It shows good adhesion to a wide range of substrates, including recycled corrugated board and low-density polyethylene, as well as curved surfaces.

Technomelt PS 9625 RE is suitable for removable and linerless labels due to its repositionability and low viscosity.

Both adhesives are approved for food packaging by U.S. Food and Drug Administration (FDA) Directive 175.105.

‘Our approach to sustainability is to create more value in the industry while reducing our environmental footprint. As well as helping our customers to become more sustainable, we aim to continuously improve our own product portfolio. Our goal is to use our technologies to help solve current and future global environmental and social challenges,’ said Ky Flamini, commercial business and sales director for tapes and labels in North America at Henkel.

Hongkong Jiuheng Group

Booth 3619

Jiuheng Group shows waybill, thermal label, packing label, document envelope, courier plastic bags and woven bags.

HP

Booth 3226

HP exhibits an HP Indigo 200K digital press with an add-on slitter allowing converters to print PS labels, slit on the press and convert off-line.

The company also promotes the HP Indigo 6K digital press. The HP Indigo fleet is part of an end-to-end approach including the Digital Pouch Factory and ABG non-stop winding and converting equipment.

Also on show is the HP PrintOS software suite, which helps converters automate the entire production line and produce high volumes.

The adjoining station on the HP stand promote the PrintOS Spot Master, showcasing how to reach spot colors and streamline the print process. HP also promotes XR Services, security and brand protection, sustainability with the CO2 calculator, and an extensive customer application showcase.

Hubei Hyf Packaging

Booth 3541

A shrink film manufacturer promotes and launches new products to meet the market demand for sustainable development. The product range has an annual output of 60,000 metric tons: PETG shrink film, RPETG shrink film and CPET shrink film.

Hontec Industries

Booth 5820

The company showcases FlexiCon, a modular, servo-driven press available in 350 web width. It supports up to 12 colors and features cold foil, delam/relam, lamination, glue killing, double-side printing and more. It operates at up to 150m/min speeds and is compatible with different substrates, from 12-micron films to 350GSM papers. It is suitable for short and long-runs. One of the exciting features is the Industry 4.0 connectivity, with fully automatic operation facilitated by EtherCat motion control from Beckhoff, ensuring high-accuracy registration.

Hontec also promotes LS-350, a laser die-cuter that does not require any tooling. It features a Luxinar laser head, and operates in-line with a flexo unit for cold foil, register printing, lamination, a semi-rotary die-cutter for long runs.

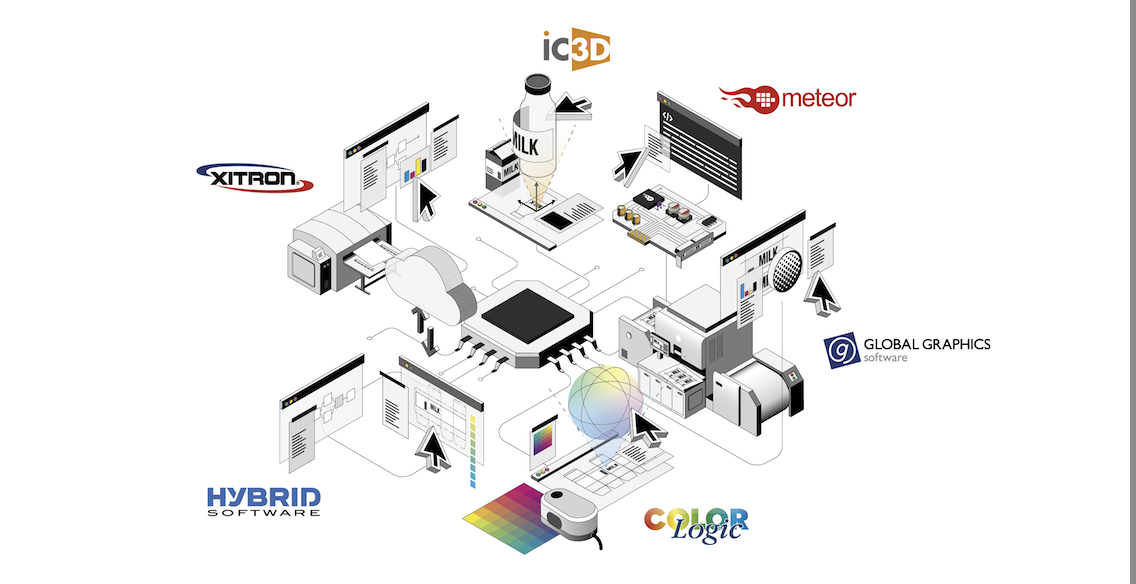

Hybrid Software

Booth 3015

Hybrid Software showcases MyCloudFlow SaaS Workflow, a 100 percent cloud-based technology based on CloudFlow, offering access through a secure environment, strong data protection and immutable backups.

Also on show is the enhanced CloudFlow’s ProofScope tool with a 3D approval system using iC3D technology for visualizing labels and embellishments on 3D shapes. Also showcasing Capture3D for precise artwork distortion on shrink sleeves and metal packaging.

Moreover, Hybrid Software promotes MyPackz SaaS PDF Job Editor, a cloud-based application offering packaging pre-press tools in a hosted SaaS model for improved efficiency, quality, and reduced error rates.

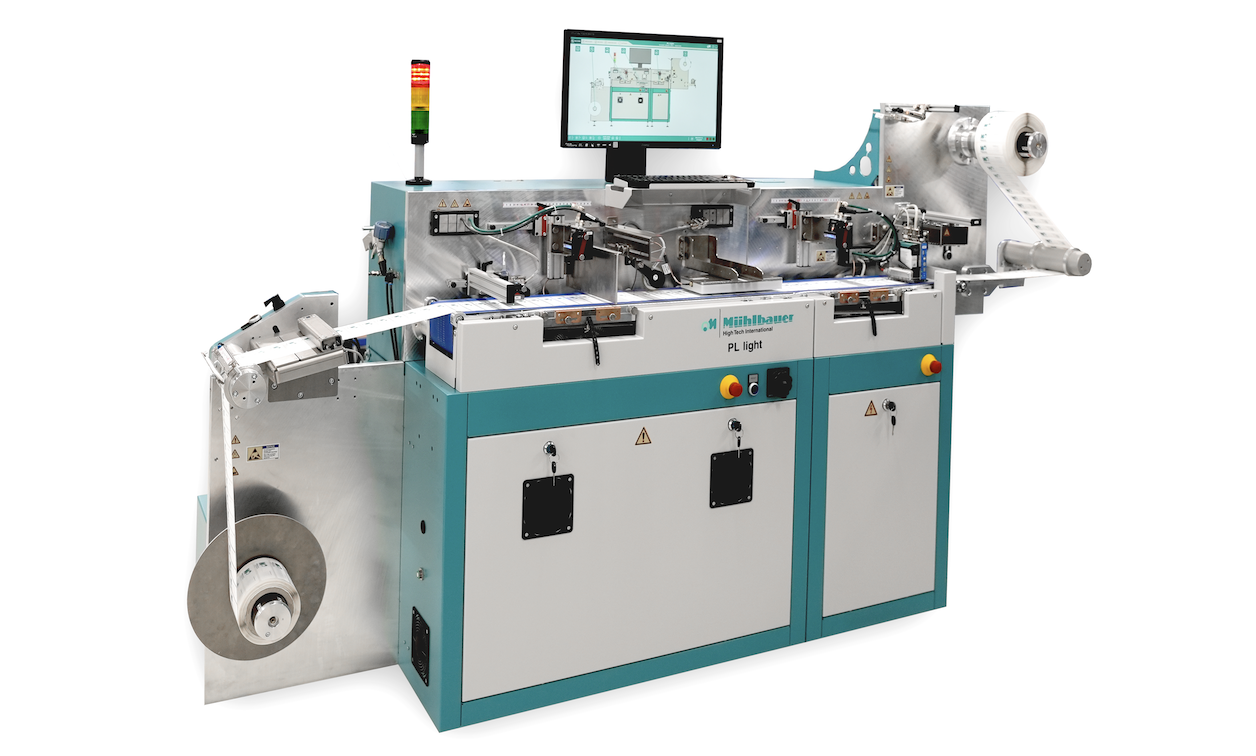

Also at the booth the team discusses SmartDFE Digital Front End, AI-accelerated RIP, Xitron’s Navigator DFE and Flexo Suite.