BST enables label production automation with TubeScan SmartData QLink

Integration into existing workflows enables automation of the entire label printing process.

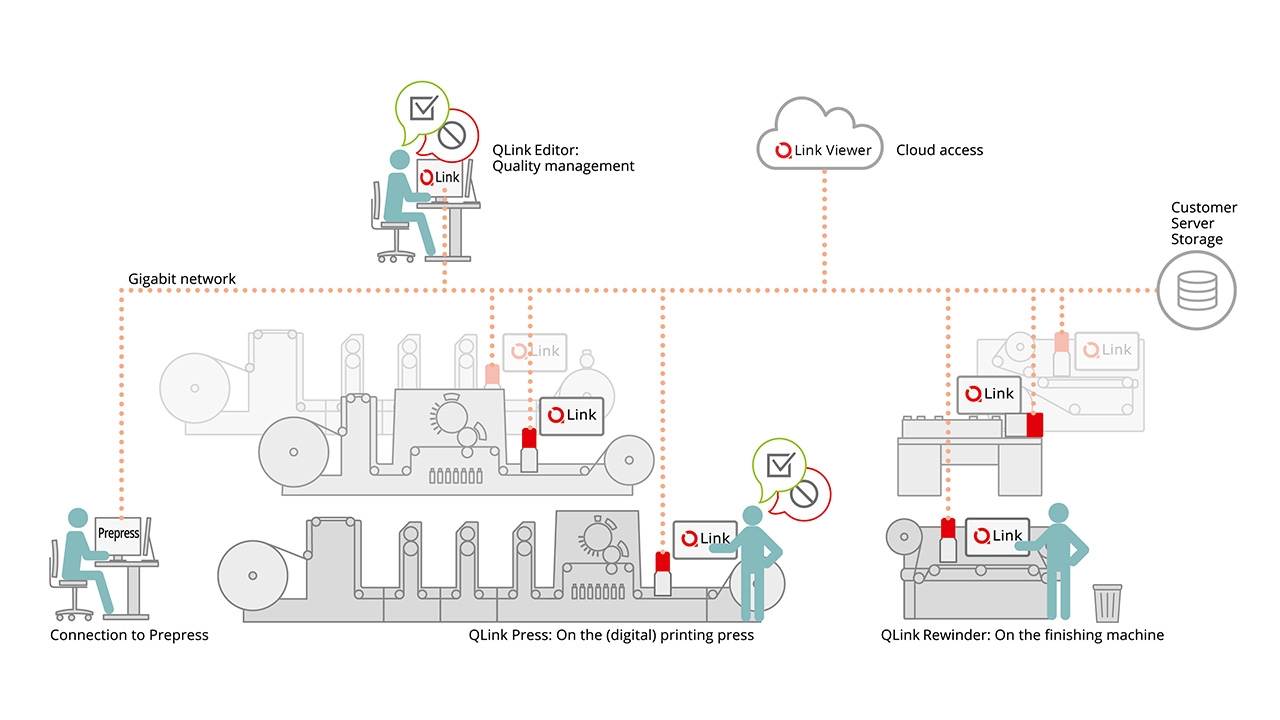

BST, a print inspection systems specialist, has introduced SmartData QLink, a system enabling integration into existing workflows to automate label printing, from pre-press to finishing, packaging and dispatch.

In the pre-press workflow, job data is generated via interfaces to common ERP and MIS systems and sent to the print department via the customer network. Connecting to popular software packages such as Esko and Hybrid enables smooth integration into existing workflows.

The pre-press workflow includes defining the artwork in the layout program, whereby inspection zones are already defined, e.g., for variable barcodes or alphanumeric sequences. The pre-press software then automatically generates the step-and-repeat.

During the printing process, TubeScan monitors the results, including variable data and image finishing inspection. Reference images can be derived from the PDF or validated by comparison with the first printed repeat.

With SmartData QLink, the roll log can be edited during printing. The ‘good’ count is displayed in real-time - per roll or cumulated over the entire job.

The new BST Dynamic Job Change technology enables a job change without stopping the machine. The TubeScan system automatically recognizes the new job and retrieves the corresponding master in real-time for comparison during the inspection, saving time and reducing waste.

Setting up the system does not require any external triggers as the synchronization with the print repeat is purely software-controlled. The TubeScan system can also inspect variable data in parallel, including variable barcodes or alphanumeric character strings.

The QLink data from the printing process is used for further processing to rectify defects. In the post-press area, SmartData QLink provides the error logs via the lead-out barcode. Based on the roll map of the job, stored defects are processed efficiently, with the TubeScan placement function controlling the converting machine and enabling precise positioning of the faulty repeat. The rewinder can also be controlled with QLink Rewinder for automatic defect positioning. Going a step further, the information printed on the finished roll can instruct a packaging robot on which rolls can ultimately be delivered.

All QLink data can be accessed and edited by the QM department via the network or retrieved via cloud.

‘Our innovative solutions offer a holistic approach to the entire printing process,’ said Joachim Barthelme, executive vice president of BST and managing director of Nyquist Systems. ‘Through our integration in pre-press, press and post-press phases, we help our customers increase their efficiency while ensuring unsurpassed print quality.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.