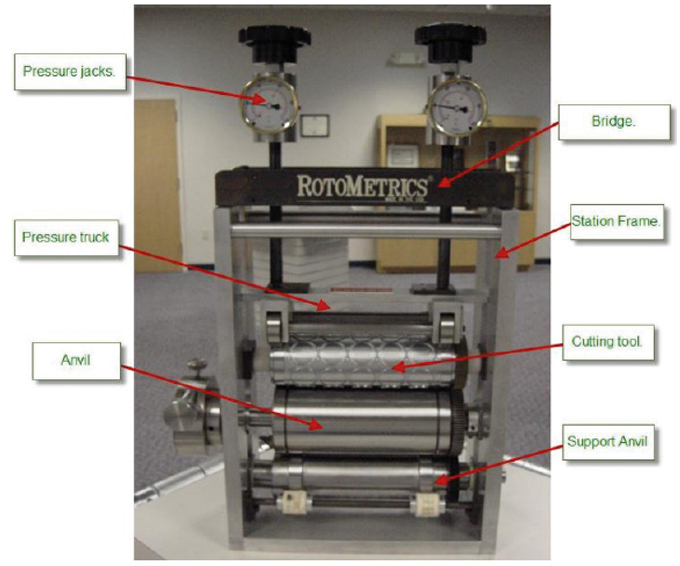

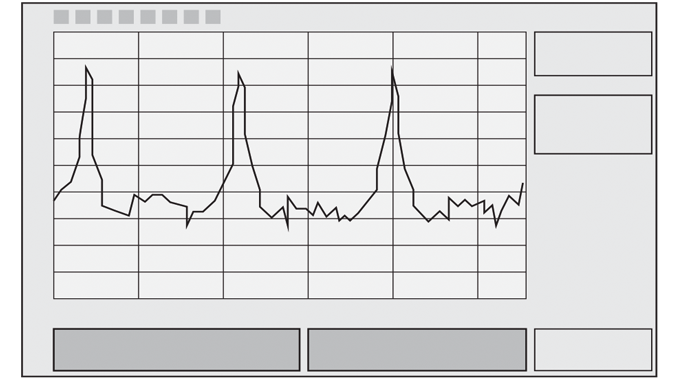

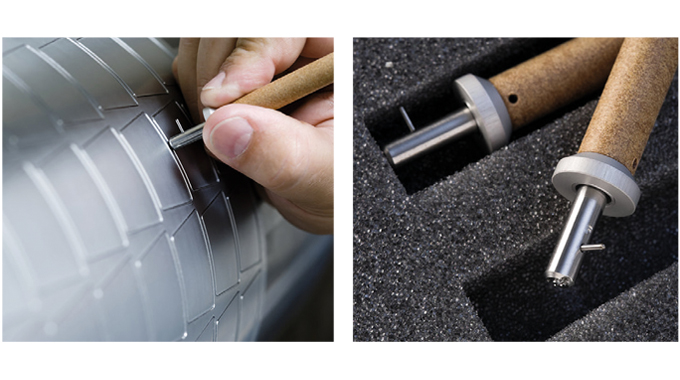

Ancillary equipment for setting, measuring, testing, monitoring and adjusting tooling

Label and package printing, with all the associated finishing stages ranging through operations such as slitting, cutting, perforating, scoring, punching, foiling and embossing, involves some of the most sophisticated and precise technology found in the whole printing industry.

Tolerances are minute when setting-up equipment to precisely cut through a face material and adhesive but without marking or damaging a release liner. Similar precision set-up challenges arise when preparing for hot stamp foiling, or complex embossing using male and female dies. Where heat is also involved, as with hot foiling, settings may even change as dies and units heat up. Continuous monitoring and ongoing adjustments are then required.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.