Optimizing the die-cutting process

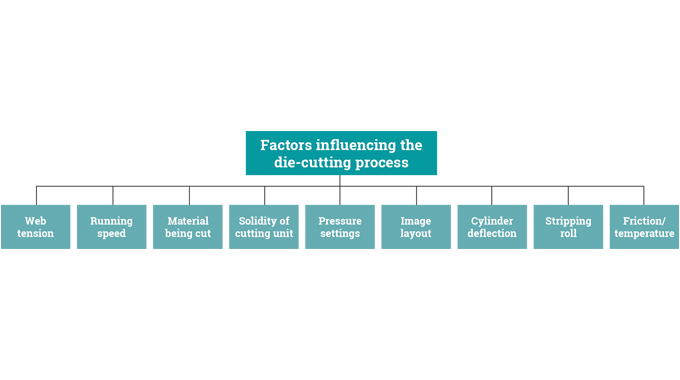

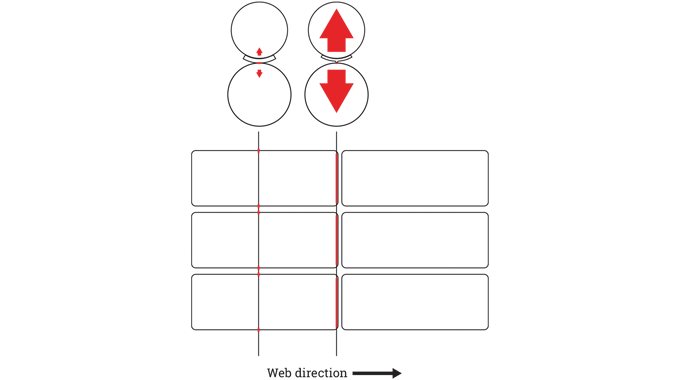

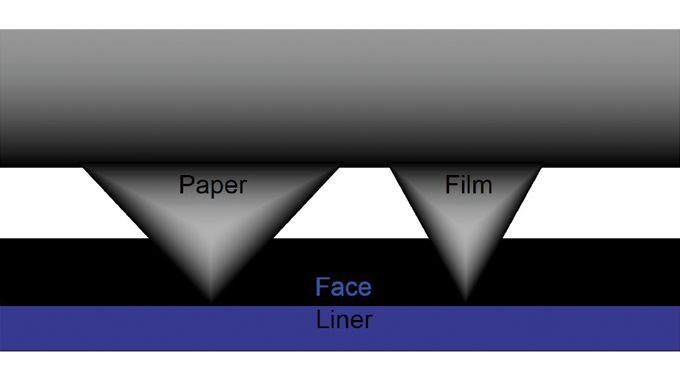

The best die-cutting results are not just reliant on the quality of the cutting die. There are many other factors involved, not the least of which is the nature of the material being converted. Other relevant or important factors can be the way the press or cutting unit is set up and run by the operator, including things like the web tension of the substrate, the running speed of the press, the die-cutting pressure, the stability of the cutting unit, or the removal of matrix waste.

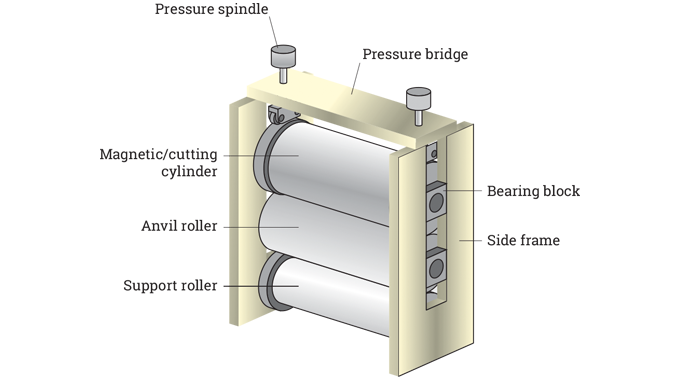

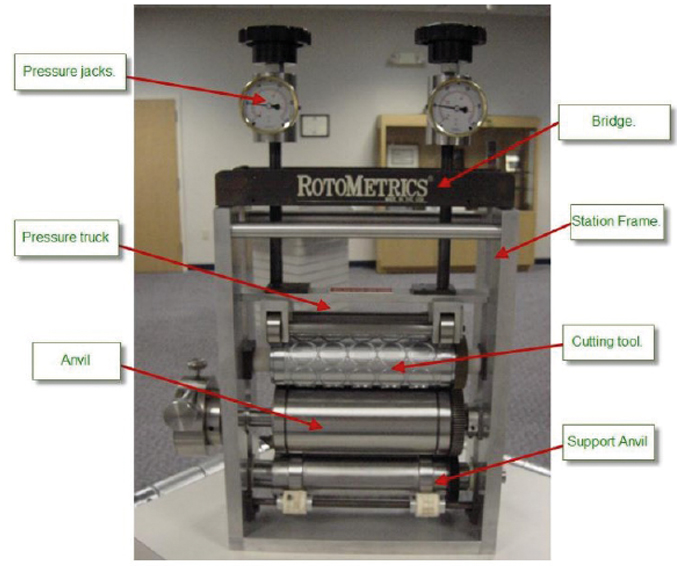

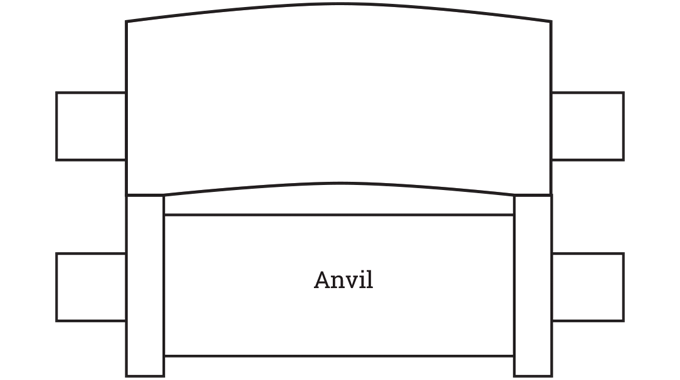

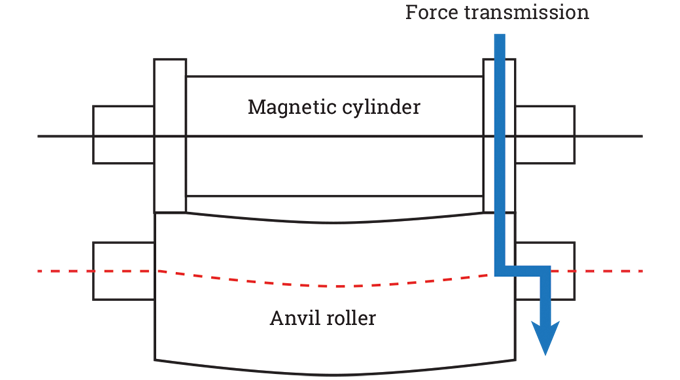

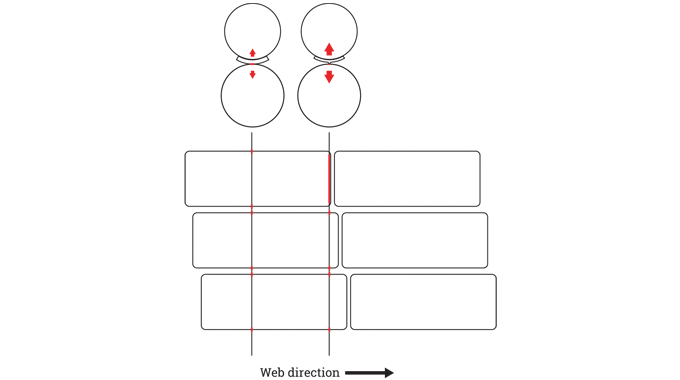

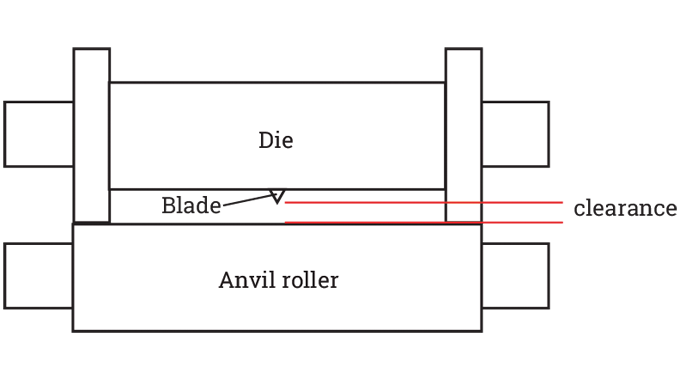

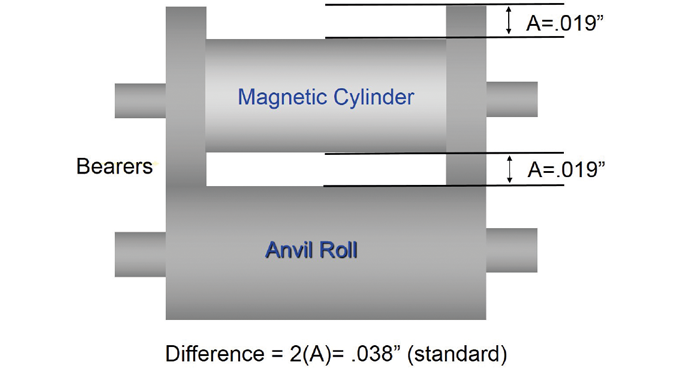

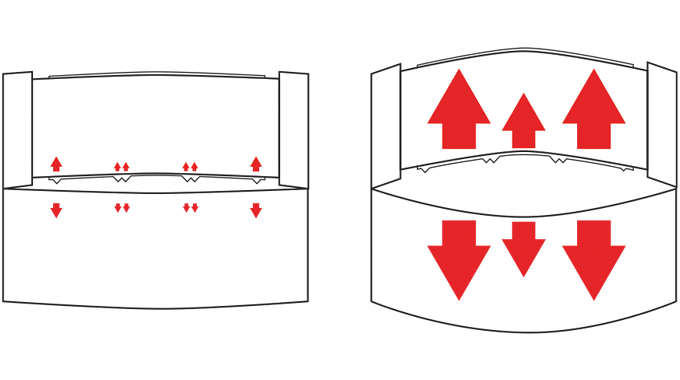

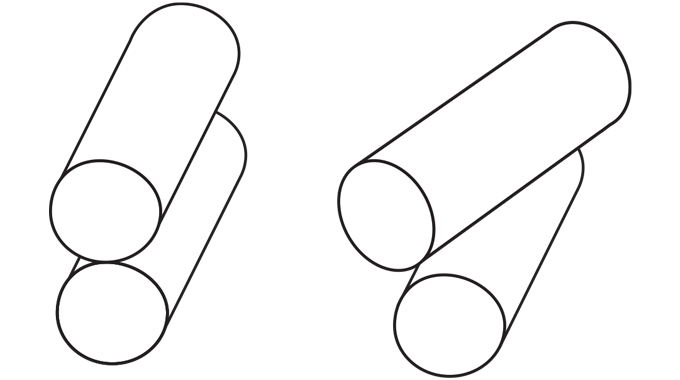

The possibility of cylinder deflection or misalignment can also be an important factor, as can anvil roller diameters, cylinders losing traction, sturdiness of the side frames, and friction in the cutting unit creating too much heat. So let’s look again at the basics of a rotary die-cutting unit (Figure 3.1) which, as can be seen, consists of:

- side frame

- bearing block

- pressure bridge

- magnetic cylinder or rotary die

- anvil roller

- support roller

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.