Holograms are available both as a label face-stock and as a foil that can be transferred to the surface of the label or pack, using the foiling processes.

WHAT IS A HOLOGRAM?

A hologram is a microscopically fine diffractive structure by which three-dimensional images are generated.

The hologram consists of two or more images which are layered in such a way that each of the images becomes visible, depending on the angle of the viewer.

The image may be made up of two layers which would comprise of a background layer and also a foreground layer. Alternatively the image may be made up of three layers, a background, middle and a foreground.

With the two-layer hologram the subject matter of the middle ground is usually superimposed over the subject matter of the background layer. This method gives a unique multi-level, multi-color effect.

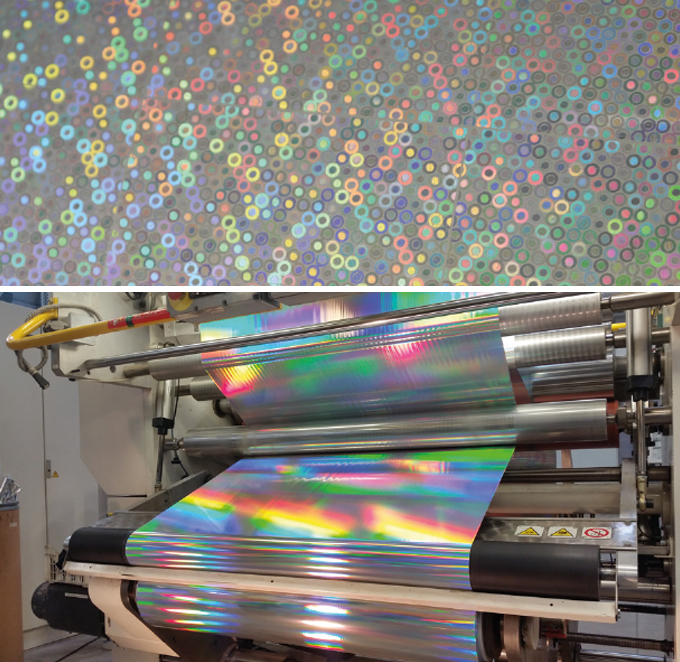

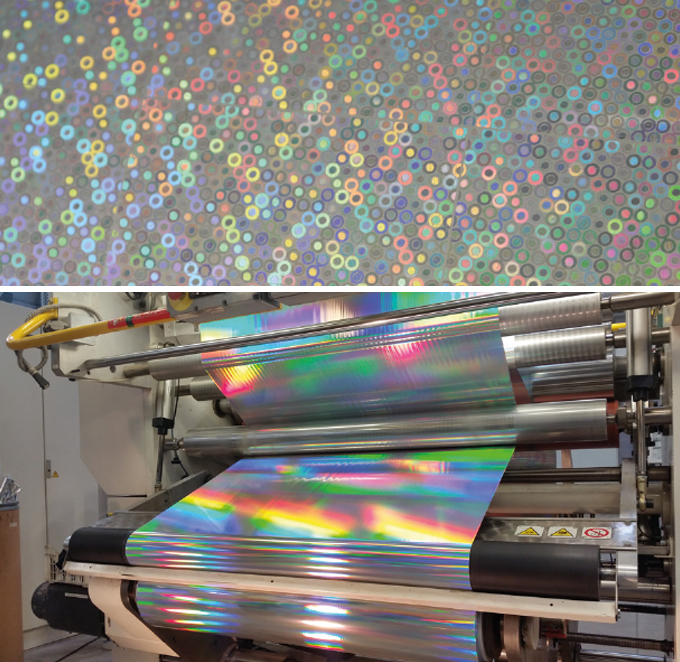

Holographic label embellishments are a relatively new product to the label industry and are now widely used in labeling graphics. (Figure 3.1)

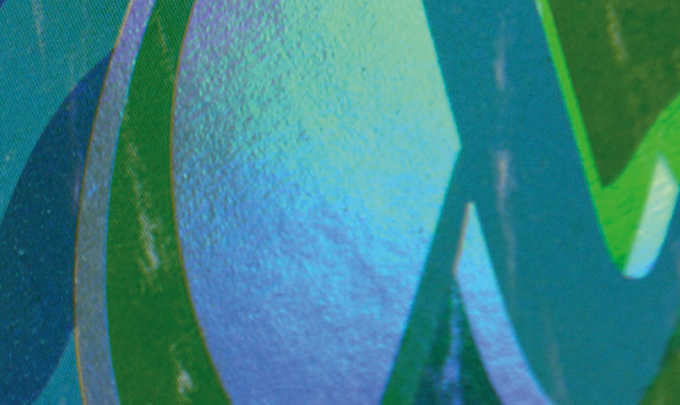

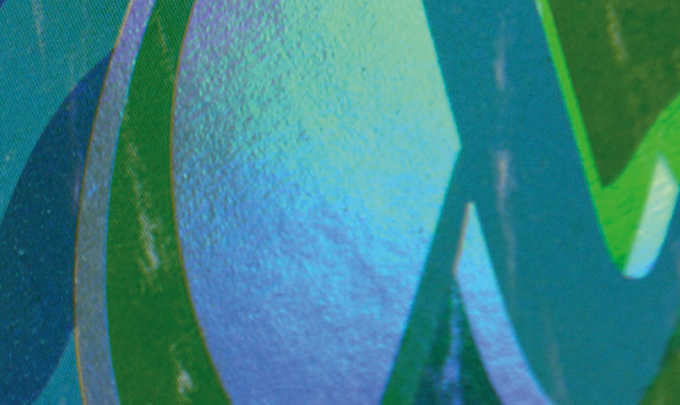

The holographic embellishment comprises of a ‘two or three-dimensional’ image which alters its position as the person viewing the image moves.

This type of imagery can produce a wide range of holographic foils which provide excellent diffraction patterns, 3D security images and anti-counterfeiting features (Figure 3.2) and because it is extremely difficult to copy a hologram, they are frequently used in high security labeling.

MANUFACTURING THE HOLOGRAPHIC IMAGE

Holograms are two and three-dimensional photographic images that appear to have depth. The holographic image is created by superimposing a two-dimensional picture of the same subject but viewed from differing angles. This type of hologram known as a ‘reflection hologram’ can be viewed in normal light.

The technology used to produce a hologram can be complex and the following sections which deal with the manufacturing process have been simplified to avoid any technical overkill. Each step highlights the production of a three-dimensional holographic image.

IMAGING

The following section explains in simple terms how a holographic image or pattern is created.

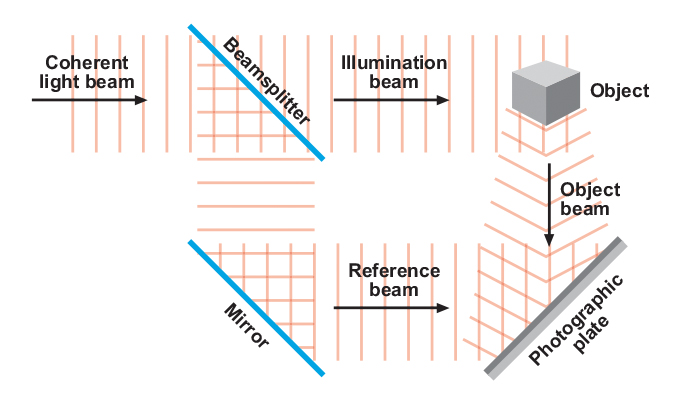

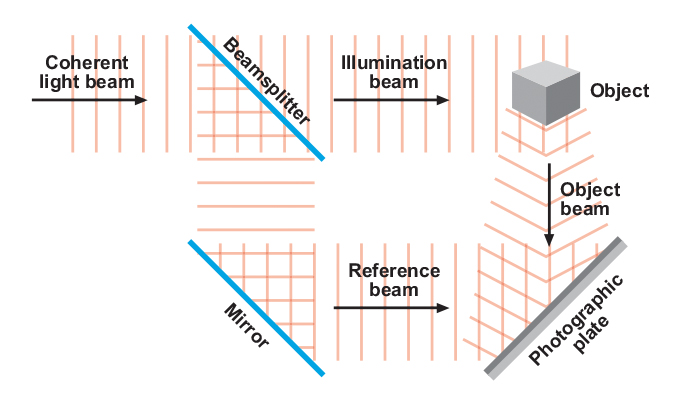

The subject of the holographic image is illuminated using a laser beam, allowing reflected light from the laser to fall on a photo-resist plate. At the same time a reference beam from the same laser is directed onto the photo-resist plate.

These two light beams react with the photo-sensitive coating and record a holographic image of the subject (see Figure 3.3).

It is most important that there is no movement of the subject during this process as this will produce an out of focus image.

The imaged photo-resist plate now holds the ‘master’ holographic image and is then processed using a photographic developing solution. After developing the surface of the plate it is similar to the surface of a gramophone record with the image made up of very fine grooves.

ELECTROPLATING

The next stage in hologram production is the electroplating process. This gives the master plate a much more robust surface. To produce a good electrical conductivity, the master is sprayed with silver paint and then immersed in a nickel tank.

An electric current is passed through the tank and a thin nickel coating is applied to the master plate.

The plate is then washed and the thin nickel coating is removed from the master plate. This nickel shim is called the ‘master-shim’ and holds a ‘negative’ image of the original subject.

By applying the same process of nickel coating using the ‘master-shim’ a ‘positive’ imaged shim can be produced.

This in turn is used to produce ‘negative’ shims which are then converted to stamper shims that are used to print/emboss the holograms.

THE EMBOSSING PROCESS

Polyester film with an acrylic coating is used as the vehicle for the holographic image. The ‘master-shims’ are located into an embossing unit and by applying high pressure combined with heat, the image from the shim produces the hologram in the polyester film.

METALIZING AND FINISHING

Metalization refers to the coating of the embossed polyester film surface with a highly reflective metal coating.

The embossed roll of film is placed in a vacuum chamber and the air is removed. An aluminum wire is positioned in the chamber and the wire is heated to 1100°C which vaporizes the aluminum wire, which in turn coats the surface of the polyester with aluminum particles. The coated film is removed from the vacuum chamber and a coating of lacquer is applied to the film that allows the holographic image or pattern to be overprinted if required. The holographic film is applied to a self-adhesive substrate using a hot foiling method of application, or alternatively a pressure-sensitive adhesive is applied to the back of holograms which in turn can be applied to a self-adhesive label.

APPLYING THE HOLOGRAM

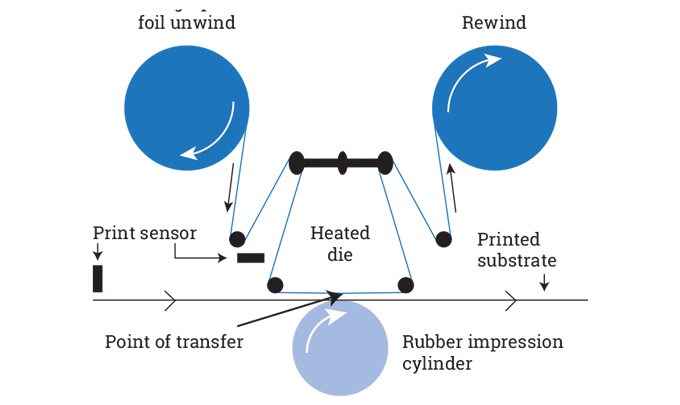

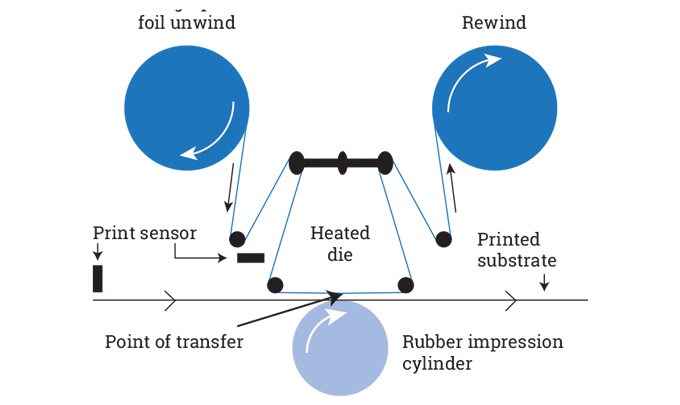

The application of a holographic image onto the top surface of a self-adhesive substrate is done using a foil-saver type system.

This operation can be carried out as an off-line or on-line application using either a rotary or flatbed hot foiling method.

To ensure accurate registration of the hologram with the printed design on the label, the foil that carries the holographic image must be synchronized with the printed web of the self-adhesive substrate.

Sensors monitor the position of the holographic image prior to entering the foiling head and the foil-saver unit will slow down or increase the speed of the holographic web to ensure that the two webs are exactly synchronized (see Figures 3.4 and 3.5).

MARKETS

Holograms and holographic face-stocks are widely used to introduce light refractive effects and iridescence to labels and packaging. As well as adding a stunning decorative feature to high-end consumer products, holograms also have potent anti-counterfeiting and brand protection properties.

They offer a wide variety of different features which can be matched to a range of security requirements, from those used in relatively low-cost commercial applications such as packaging and labels, to a more sophisticated security method of protecting currency.

Holograms incorporating both overt and covert machine readable features, variable data and unique serial numbering have become powerful tools in the prevention of counterfeiting of documents, labels, seals and tags.

In summary, holograms used for anti-counterfeiting and brand protection have a number of benefits;

-

Virtually impossible to replicate

-

Cannot be reproduced by photocopiers or scanners

-

Will expose any attempts at alteration or removal from a document or label

-

Are easy to authenticate with the naked eye

-

Require specialist knowledge and equipment to originate and manufacture

-

Cannot be replicated by reproduction using any conventional printing process