EskoArtwork HD Flexo proves its worth in Italy

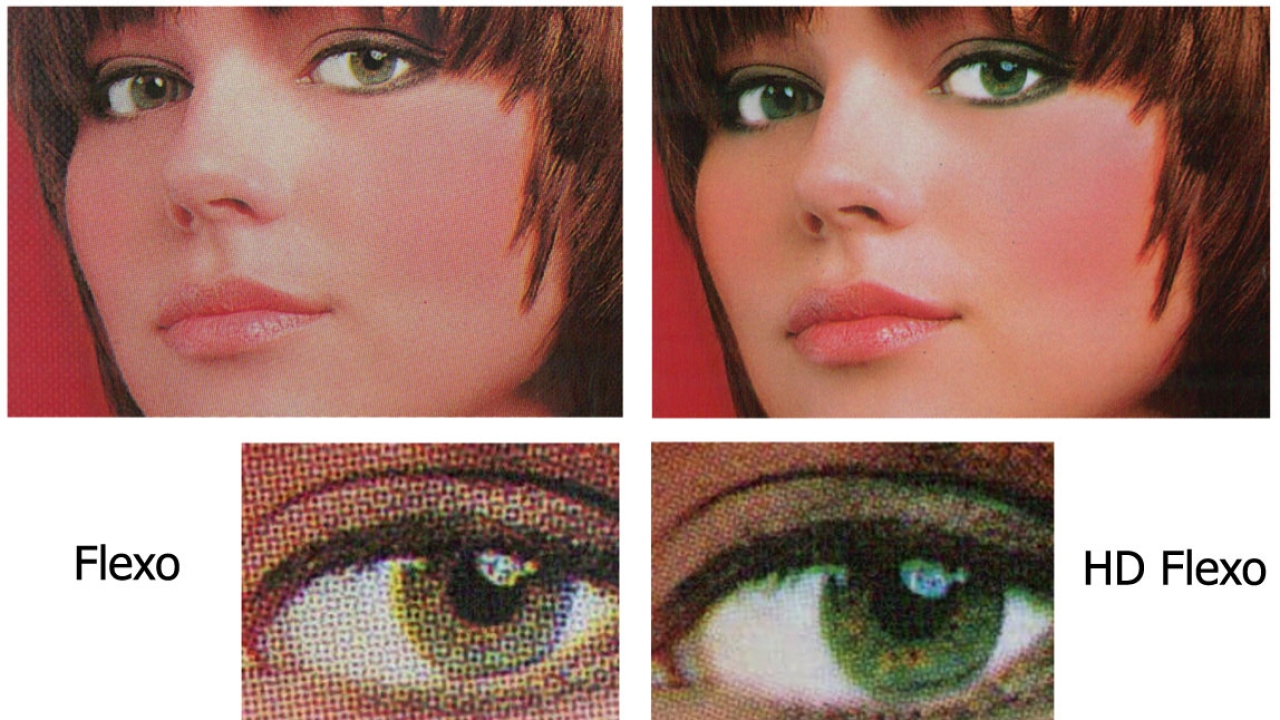

To compete with the quality of offset and gravure printing, flexo plate manufacturing needs high resolution optics and excellent screening technology. By combining 4000 dpi HD optics with advanced screening, EskoArtwork’s HD Flexo delivers sharper and more accurate imaging, and Italy now has 20 of these systems in use or about to be installed.

Parma-based Zincopar was one of the first. Owner Massimo Cipolla explained: ‘After trialing the technology it exceeded our expectations and showed us a new way of working which has brought positive results, such as higher resolution, increased print definition and better ink transfer. This has helped us win new business from gravure.’

At Forli-based Sidac, a company that designs and manufactures flexible plastic packaging and labels for food, beverages and detergents, HD Flexo accounts for around 15% of output on PET, PE, PP, PVC. Luca Mazzotti, managing director, commented: ‘We began using HD Flexo after seeing the quality gap between flexo and gravure getting narrower and narrower. It is perfect for customers who want the quality of gravure without the associated costs.’

Monza-based Digital Flex, (part of New Roveco), provides ready-to-print flexo plates. Production manager Andrea Vergnano said: ‘After intensive trials we introduced HD Flexo and our customers were really impressed. The 4000 dpi optics and HD screening technology allow fine gradations that fade to zero, while the increased color gradation results in a wider color gamut.’

Flexocit of Brescia, a flexo production company specializing in food packaging and part of Gerosa Group, has also embraced the HD Flexo 4000 dpi technology and achieved EskoArtwork certification for printing with this system using screen rulings higher than 70 lines per square centimeter.

GPS Packaging, which processes paper and plastic shopping bags and labels, has been using HD Flexo for six months. ‘HD Flexo has enabled us to increase our quality and we’re very impressed with the results. When we print soft and smooth vignettes, which is very important for printing high-quality shopping bags and beverage labels,’ said managing director and president Daniele Grotto.

Rotoflex is a flexo service provider based in Sesto San Giovanni (MI) and Reggio Emilia. ‘We began testing over a year ago and we’re very satisfied with the results. It ensures sharper and more accurate imaging, and allows us to print with more than 60 lines. It is an excellent alternative to rotogravure printing,’ commented owner Giovanni Visinoni.

Among Rotoflex’s customers is Fiorini International, which supplies paper packaging for the food industry, and also operates in the fashion and clothing sector. Fiorini opted for HD Flexo to print on one-side coated paper. HD Flexo is now enabling Fiorini to achieve stunning results with high screen rulings, very clean whites and well-defined detail.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.