Autumn Graphics invests in Miraclon’s Shine LED Lamp Kit

Packaging graphics provider benefits from value and process efficiency gains after switching to LED technology.

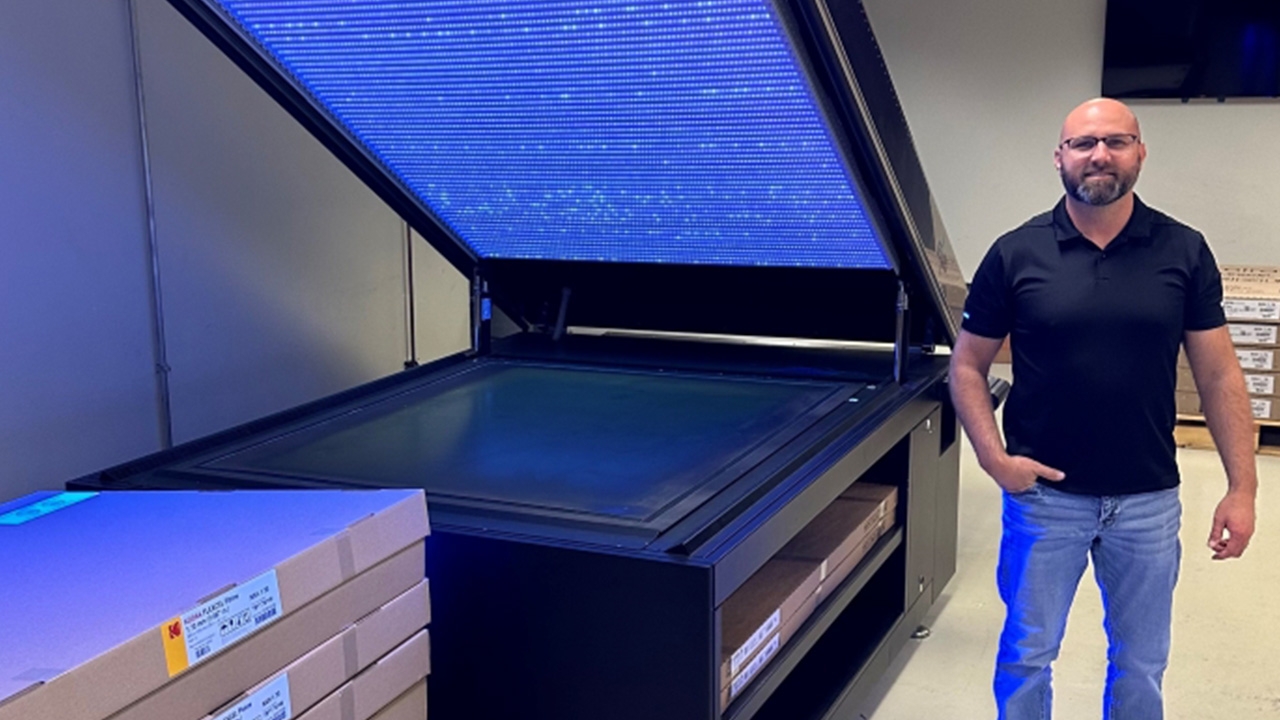

Wess Gano, operations manager at Autumn Graphics

Autumn Graphics has invested in the Shine LED Lamp Kit, innovated by Miraclon as a simple, low-cost route from inconsistent fluorescent exposure to the multiple advantages of LED technology.

Headquartered in London, Ontario, Autumn Graphics provides converters, printers, agencies and consumer product clients with pre-media production, plate production, brand management, 3D packaging development and print production technical services.

Founded in 1982, the company has been a Flexcel NX System user since 2008, having been a beta site for the technology. The company has multiple Flexcel NX imagers and processing lines in London and Fayetteville, and on-site at customers, and last year completed the Miraclon Certification Program for Flexcel NX Plates.

Autumn has regularly beta tested Miraclon innovations, so evaluating the Shine LED Lamp Kit was a logical decision. The kit has been retrofitted to a plate exposure frame at the company’s location in Fayetteville, Arkansas.

‘When Miraclon approached us and explained the thinking behind the product we saw it as another opportunity for improving our processes,’ said Wess Gano, operations manager at Autumn Graphics. ‘We looked at what was involved closely, as we do whenever we consider process changes — we thoroughly examine everything to ensure we’re not introducing any risks — and decided that taking this path to LED offered significant efficiency gains.

‘Exposures are faster, because there’s no time wasted warming up and cooling down the lamps, and more consistent. Operators spend much less time adjusting exposure times to compensate for lamp variations. We hired an electrician and handled the installation ourselves, working with clear documentation from Miraclon. All in all, the whole changeover was straightforward and met our expectations.’

According to Miraclon, by utilizing customers’ existing fluorescent exposure frames, the Shine LED Lamp Kit can be retrofitted in the field in a few hours. For a fraction of the cost of a new LED exposure unit, users benefit from consistent, predictable and much longer operating life (up to 5,000 hours compared to 800 hours for fluorescent tubes), faster exposures (by 20 percent or more), and enhanced sustainability performance by improving plate consistency, and reducing waste and energy consumption.

These features won the Shine LED Lamp Kit a unique double at this year’s FTA Excellence in Flexography Awards, winning top awards for both sustainability and technical innovation.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.