New products special

With Labelexpo Europe postponed to next year, L&L highlights some of the new products which were due to be shown

Accraply - Acme Rolltech - ALE - Berhalter - boon-tech - Durico - Dynic (UK) - Esatec - FAG Graphic Systems - Fix-a-Form International - Flint Group - GEW - Glunz & Jensen - Grafotronic - The Grey Elephant - HCI - Hoaco - Hoya - Innovia Films - IST Metz - Ixthus Instrumentation - Kernow Coatings - LabelTraxx - Laserclean - Lemorau - MagVision - Maxcess/Rotometrics - Merobel - Miyakoshi - MPS - Pantec - Polar - Premier Coating & Converters - Rotutech Hispania - Side Graphics - Steinbeis Papier - Synthogra - Taghleef - TEG Technologies - Tootech - Toyobo - Tri-Tronics - VPF - Wacker - Zecher

Accraply has launched its next-generation seaming system, Accraply Revolve, which is designed to improve output, reduce downtime and enhance productivity. The Revolve platform has an intuitive design that reduces operator dependency and enables the user to streamline and improve operations. Accraply’s modular and configurable seaming system offers flexibility, customization and scalability.

Accraply has launched its next-generation seaming system, Accraply Revolve, which is designed to improve output, reduce downtime and enhance productivity. The Revolve platform has an intuitive design that reduces operator dependency and enables the user to streamline and improve operations. Accraply’s modular and configurable seaming system offers flexibility, customization and scalability.

Acme Rolltech, Indian manufacturer of ceramic anilox rolls and sleeves, has unveiled its new engraving patterns: AHDW for screen-type effect for high opacity white printing in single pass, and ATAC for screen- or embossing-type heavy varnish deposition to achieve a raised and tactile effect. Acme Rolltech supplies anilox rolls and sleeves to narrow web flexo, CI flexo, wide web flexo, offset, corrugated, coating and specialty film coating applications.

ALE has introduced its new Twin Track technology to the laser engraving sector. This is a new hardware and software interface for ALE engraving machines, particularly suited to engrave high-volume, flat-bottomed cell structures. The cell structures can be defined in the conventional manner, using screen count and screen angle.

ALE has introduced its new Twin Track technology to the laser engraving sector. This is a new hardware and software interface for ALE engraving machines, particularly suited to engrave high-volume, flat-bottomed cell structures. The cell structures can be defined in the conventional manner, using screen count and screen angle.

Berhalter has unveiled the new Swiss Die-Cutter B6, delivering 500 strokes per minute and featuring individually controlled die-cutting motion, flexibly adjustable opening level of the punching tool, digitally monitored penetration depth and a new active foil guide built into the punching tool. Also on show is the new CUTcontrol IoT technology. It can link all production processes and provide the KPIs for strategic production planning including live data streams from machine, accessories and punching tools. The company offers tools for die-cutting flat packaging lids, deep-drawn lids, paper labels and IML labels.

Berhalter has unveiled the new Swiss Die-Cutter B6, delivering 500 strokes per minute and featuring individually controlled die-cutting motion, flexibly adjustable opening level of the punching tool, digitally monitored penetration depth and a new active foil guide built into the punching tool. Also on show is the new CUTcontrol IoT technology. It can link all production processes and provide the KPIs for strategic production planning including live data streams from machine, accessories and punching tools. The company offers tools for die-cutting flat packaging lids, deep-drawn lids, paper labels and IML labels.

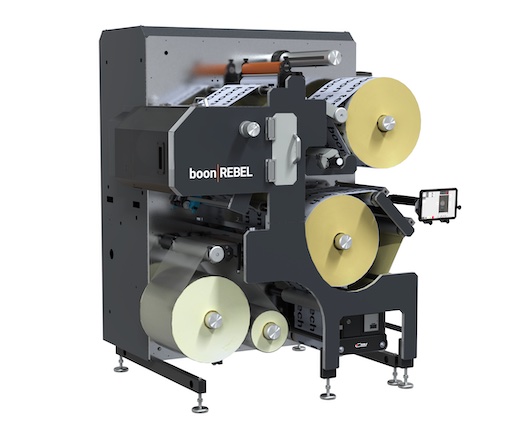

boon-tech, until recently known as Worldwide Label Equipment (WLE), has launched a new slitter rewinder, Exigo, and a compact digital finishing machine, Rebel. boon-tech offers ‘plug and play’ auxiliary equipment such as finishing systems, fan-folding equipment and fully and semi-automatic core cutters. Read more on page 14.

boon-tech, until recently known as Worldwide Label Equipment (WLE), has launched a new slitter rewinder, Exigo, and a compact digital finishing machine, Rebel. boon-tech offers ‘plug and play’ auxiliary equipment such as finishing systems, fan-folding equipment and fully and semi-automatic core cutters. Read more on page 14.

Durico has launched direct thermal films which include a phenol-free product for safer human health and heat stability, and products resistant to harsh environments such as solvent, alcohol, hot water and blood.

Dynic (UK) has launched a new textile satin for pigmented color inkjet systems, various high opacity thermal transfer ribbons for printing upon dark substrate applications and a range of new sustainable and 100 percent recycled textile printing media.

Esatec has unveiled MFL350, its new modular feeding line developed for various applications such as printing, labeling, affixing, inspection, reject of faulty products. Several configurations allow to meet required product needs and their flexible design can be adapted to many production styles.

Esatec has unveiled MFL350, its new modular feeding line developed for various applications such as printing, labeling, affixing, inspection, reject of faulty products. Several configurations allow to meet required product needs and their flexible design can be adapted to many production styles.

FAG Graphic Systems has launched Flex3Pro V6.x software with a QR code reading function for workflow integration. It can read QRCodes 21x21 ISO-8859-1 with a target size of max 1.4mm x 1.4mm on transparent flexo plates. The QR code can be generated from different software. This allows each individual lasered/manufactured plate to be uniquely identified and tracked. The reading of the QR code is integrated in the Fleyeplus option V6 software.

Fix-a-Form International has unveiled the Rotofix module of its latest multi-page leaflet label equipment. Offering machinery such as the AutoFix, FastFix and the Fold&Fix, all its systems are designed to manage the most complex products. The machinery is suited to short runs that require frequent changeovers. The equipment offers up to a 500mm web base, the option of 2 Rotofix heads on one machine, in-line and cross webbed hot or cold glue options.

Fix-a-Form International has unveiled the Rotofix module of its latest multi-page leaflet label equipment. Offering machinery such as the AutoFix, FastFix and the Fold&Fix, all its systems are designed to manage the most complex products. The machinery is suited to short runs that require frequent changeovers. The equipment offers up to a 500mm web base, the option of 2 Rotofix heads on one machine, in-line and cross webbed hot or cold glue options.

Flint Group has launched its new Evolution Series of inks and coatings. The series aims to deliver greater recyclability and reduced CO2 emissions. The first two products in the series, both UV-flexo, assist in boosting the recyclability of PET packaging with shrink sleeves or self-adhesive labels. The first is the Evolution Deinking Primer, which causes an ink to release from crystallizable polyester shrink sleeves (cPET) in the recycling process without contamination. The second, Evolution Caustic Resistant OPV, is an overprint varnish to facilitate recycling of PET bottles utilizing pressure-sensitive labels.

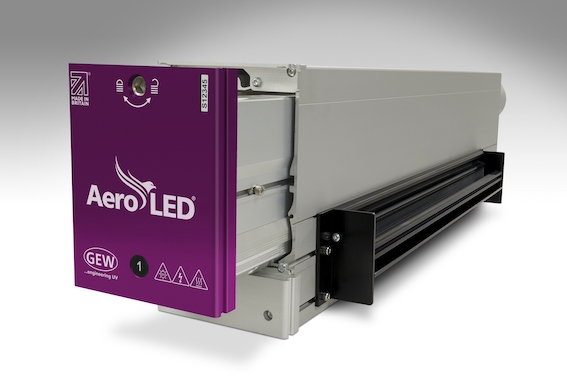

GEW has launched AeroLED, a fully air-cooled, high-powered UV LED system for all applications up to 60cm (23in) wide, claimed to eliminate many of the operational problems in existing air-cooled systems on the market. The system features a new air-cooling process with filtered air distributed from a single centralized fan located away from the press and exits through the UV lampheads for quiet operation. According to GEW, the remote positioning of the fan avoids common problems caused by ink mist and dust ingress, while large air filters reduce the filter replacement cycle. There is no need for integrated fans or electronics in the individual lampheads, which eliminates the high-pitched noise and contamination issues that these bring.

GEW has launched AeroLED, a fully air-cooled, high-powered UV LED system for all applications up to 60cm (23in) wide, claimed to eliminate many of the operational problems in existing air-cooled systems on the market. The system features a new air-cooling process with filtered air distributed from a single centralized fan located away from the press and exits through the UV lampheads for quiet operation. According to GEW, the remote positioning of the fan avoids common problems caused by ink mist and dust ingress, while large air filters reduce the filter replacement cycle. There is no need for integrated fans or electronics in the individual lampheads, which eliminates the high-pitched noise and contamination issues that these bring.

Glunz & Jensen has launched a new family of exposure units for flexo and letterpress plates, also in multifunctional configuration (i.e., exposure, dryer, and light finisher in one unit). The equipment series, FlexiPose 360, FlexiPose 470, FlexiPose 520, expose analog and digital plates in all the standard sizes available up to 52 x 80in. The design has improved over the previous generation by introducing innovations such as full remote support for both diagnostics and future firmware updates. The units will be ready for shipment starting September 2022.

Glunz & Jensen has launched a new family of exposure units for flexo and letterpress plates, also in multifunctional configuration (i.e., exposure, dryer, and light finisher in one unit). The equipment series, FlexiPose 360, FlexiPose 470, FlexiPose 520, expose analog and digital plates in all the standard sizes available up to 52 x 80in. The design has improved over the previous generation by introducing innovations such as full remote support for both diagnostics and future firmware updates. The units will be ready for shipment starting September 2022.

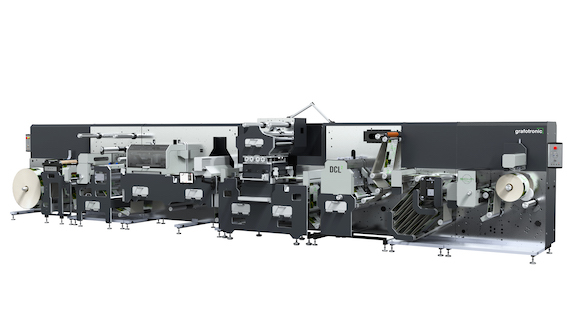

Grafotronic has launched six new models developed with a strong focus on automation and performance. The new Haptic Series for wine and cosmetics includes new hot stamping, embossing and flatbed screens. The new digital Edgeless Sci-Fi Laser with invisible cut and digital embellishment features is also now available. Grafotronic has unveiled the latest automation package for the DCL, running with less downtime and reaching speeds never seen before. The energy-saving HI3 inspection slitter rewinder with 100 percent inspection and high-speed slitting is in its third generation and is the first of the new environmentally optimized series of machines from Grafotronic. All devices employ the company’s Connected+ technology – now available worldwide.

Grafotronic has launched six new models developed with a strong focus on automation and performance. The new Haptic Series for wine and cosmetics includes new hot stamping, embossing and flatbed screens. The new digital Edgeless Sci-Fi Laser with invisible cut and digital embellishment features is also now available. Grafotronic has unveiled the latest automation package for the DCL, running with less downtime and reaching speeds never seen before. The energy-saving HI3 inspection slitter rewinder with 100 percent inspection and high-speed slitting is in its third generation and is the first of the new environmentally optimized series of machines from Grafotronic. All devices employ the company’s Connected+ technology – now available worldwide.

The Grey Elephant has unveiled its Brain4Tools and Scan4Tools products, developed to enhance seamless information retrieval and exchange in the workflow, saving significant amount of money and time for printers. Its tools speed up information sharing at every stage of the workflow, includes departments like ERP, graphics, press, tooling and archiving. By making accurate information available among all these departments The Grey Elephant’s products increase efficiency, contribute to cost savings and upgrades the decision-making process.

HCI has launched its new FP-X250-2 shrink sleeve seaming machine with rewind auto splicing, ultrasonic lay-flat measuring and solvent detection technology, allowing seaming and doctoring on the same system. The machine runs at 500m/min and has turret winding stations. HCI also provides a converting equipment line of slitting, seaming, inspection and cutting for shrink sleeves.

HCI has launched its new FP-X250-2 shrink sleeve seaming machine with rewind auto splicing, ultrasonic lay-flat measuring and solvent detection technology, allowing seaming and doctoring on the same system. The machine runs at 500m/min and has turret winding stations. HCI also provides a converting equipment line of slitting, seaming, inspection and cutting for shrink sleeves.

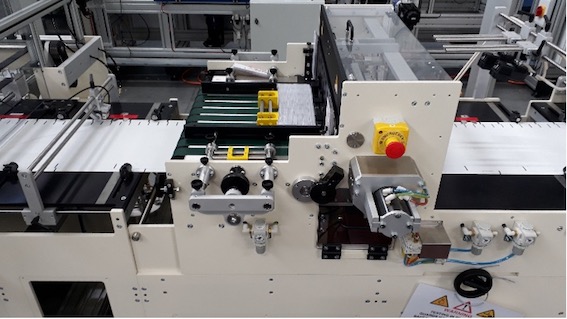

Hoaco has launched its multi-station rotary die-cutting (RDC) machines with up to 32 stations in a single system. The company has developed fully integrated RDC + flatbed die-cutting, laser-cutting, pick-n-place, printing and packaging machines. Hoaco rotary die-cutting machines are suitable for manufacturing of multi-layered products. The equipment enables die-cutting, converting, laminating, CCD registration and inspection in a single pass. RDC machines are used in applications such as electronics, medical and cosmetics, automobile, labels and printing industry. It can accommodate materials of different density, thickness and composition. With its multi-station movable design and customizable die-cutting stations, the finishing equipment is suitable for high volume and tight tolerance applications.

Hoaco has launched its multi-station rotary die-cutting (RDC) machines with up to 32 stations in a single system. The company has developed fully integrated RDC + flatbed die-cutting, laser-cutting, pick-n-place, printing and packaging machines. Hoaco rotary die-cutting machines are suitable for manufacturing of multi-layered products. The equipment enables die-cutting, converting, laminating, CCD registration and inspection in a single pass. RDC machines are used in applications such as electronics, medical and cosmetics, automobile, labels and printing industry. It can accommodate materials of different density, thickness and composition. With its multi-station movable design and customizable die-cutting stations, the finishing equipment is suitable for high volume and tight tolerance applications.

Hoya has introduced its latest air-cooled UV-LED system, NX series, for flexo printing. The NX series comes with digital features such as status indicators, neuron microchip network system, digital AC/DC converter and data logging. It brings added value for retrofit purpose. The NX series offers balance of a high max peak irradiance and a significant dose, works without chiller and air duct system.

Hoya has introduced its latest air-cooled UV-LED system, NX series, for flexo printing. The NX series comes with digital features such as status indicators, neuron microchip network system, digital AC/DC converter and data logging. It brings added value for retrofit purpose. The NX series offers balance of a high max peak irradiance and a significant dose, works without chiller and air duct system.

Innovia Films has launched a new high yield, matte white, 60 micron in-mold-label film with high opacity. When used on small-to-medium size, PP or PE containers, an all-polyolefin mono-material container can be produced. This enables the final pack to be fully recyclable, meeting the Plastic Recyclers Europe packaging design recommendations. QB is a cavitated, white gloss film for pressure sensitive labeling applications, which has a coating receptive surface on one side. This film is EU food contact compliant.

Innovia Films has launched a new high yield, matte white, 60 micron in-mold-label film with high opacity. When used on small-to-medium size, PP or PE containers, an all-polyolefin mono-material container can be produced. This enables the final pack to be fully recyclable, meeting the Plastic Recyclers Europe packaging design recommendations. QB is a cavitated, white gloss film for pressure sensitive labeling applications, which has a coating receptive surface on one side. This film is EU food contact compliant.

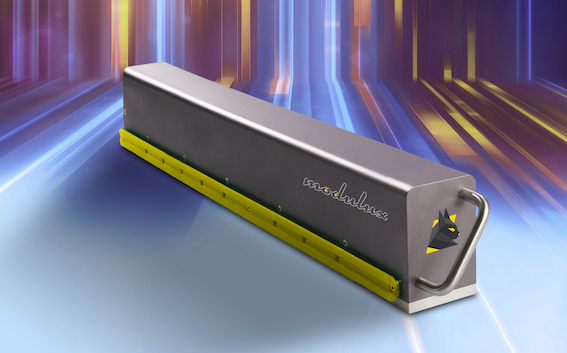

IST Metz has introduced modulux LED, a new spin-off brand focusing on modular LED systems for narrow or mid-web presses. Modulux LED curing units allow configuration of the press according to converter requirements. The curing system reduces use of LEDs at a higher peak and radiant intensity. It comes with the instant on/off function to eliminate energy use in stand-by mode.

IST Metz has introduced modulux LED, a new spin-off brand focusing on modular LED systems for narrow or mid-web presses. Modulux LED curing units allow configuration of the press according to converter requirements. The curing system reduces use of LEDs at a higher peak and radiant intensity. It comes with the instant on/off function to eliminate energy use in stand-by mode.

Ixthus Instrumentation now offers a new version of NCTE 2300 torque sensor series for lower torque-range measurement tasks down to 0.5nm. The series now covers a torque range from 100nm down to 0.5nm. It comes with measurement bandwidth up to 1,000Hz, speeds to 10,000rpm and accuracy to 0.5 percent. These non-contacting, long life sensors are suitable for torque, speed, shear and angle measurement in precision mechanics, test beds for smaller electric motors and engines, machine tool performance control, controlled screw fastening and capping operations and robotic manipulators.

Ixthus Instrumentation now offers a new version of NCTE 2300 torque sensor series for lower torque-range measurement tasks down to 0.5nm. The series now covers a torque range from 100nm down to 0.5nm. It comes with measurement bandwidth up to 1,000Hz, speeds to 10,000rpm and accuracy to 0.5 percent. These non-contacting, long life sensors are suitable for torque, speed, shear and angle measurement in precision mechanics, test beds for smaller electric motors and engines, machine tool performance control, controlled screw fastening and capping operations and robotic manipulators.

Kernow Coatings has launched its new textured digitally printable synthetic self-adhesive labelstock. Printable by all established dry toner laser and water-based inkjet technologies as well as traditional screen and flexo, this new textured labelstock allows converters and end-users to produce textured labels without the need for lamination films or varnishes. Suitable for beverage cans and bottles as well as healthcare products, the substrate gives a ‘grippy feel’ and moisture resistance. The substrate is approved for use on the OKI Pro dry toner series and suitable for use with Epson water-based inkjet roll fed printers.

Kernow Coatings has launched its new textured digitally printable synthetic self-adhesive labelstock. Printable by all established dry toner laser and water-based inkjet technologies as well as traditional screen and flexo, this new textured labelstock allows converters and end-users to produce textured labels without the need for lamination films or varnishes. Suitable for beverage cans and bottles as well as healthcare products, the substrate gives a ‘grippy feel’ and moisture resistance. The substrate is approved for use on the OKI Pro dry toner series and suitable for use with Epson water-based inkjet roll fed printers.

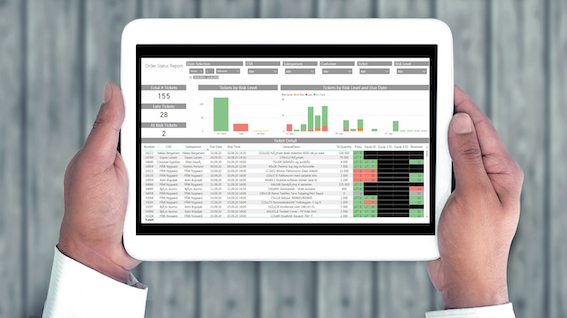

Label Traxx has unveiled Version 9 with a redesigned, modern user interface. It offers new primary navigation tools and increased customization options to enhance the user experience. Job Costing and Shop Floor Data Collection modules have been improved to support new roll tracking features, remote access and a new operator user experience. Label Traxx and Batched have launched the third general release of their automated planning and scheduling product. Along with performance and usability improvements, this release contains a new set of features that blend artificial intelligence and machine learning with human engagement. Siteline, Label Traxx’s customer engagement module, offers new features to further simplify the product management and reordering processes. The tool now offers artwork approval capabilities with a high level of functionality.

Label Traxx has unveiled Version 9 with a redesigned, modern user interface. It offers new primary navigation tools and increased customization options to enhance the user experience. Job Costing and Shop Floor Data Collection modules have been improved to support new roll tracking features, remote access and a new operator user experience. Label Traxx and Batched have launched the third general release of their automated planning and scheduling product. Along with performance and usability improvements, this release contains a new set of features that blend artificial intelligence and machine learning with human engagement. Siteline, Label Traxx’s customer engagement module, offers new features to further simplify the product management and reordering processes. The tool now offers artwork approval capabilities with a high level of functionality.

Laserclean has unveiled a new version of the anilox roll cleaning system ALCS 1000 SF laser cleaning machine. The Laserclean narrow web machine ALCS 1000 SF is a compact system. Chain, wheels and bearings do not need removal and after cleaning the roller can be used immediately. The cleaning cycle is five minutes on average and consumables such as granulates, chemicals or water are not required. The system can be connected on Wi-Fi and has multiple pre-selected cleaning programs.

Laserclean has unveiled a new version of the anilox roll cleaning system ALCS 1000 SF laser cleaning machine. The Laserclean narrow web machine ALCS 1000 SF is a compact system. Chain, wheels and bearings do not need removal and after cleaning the roller can be used immediately. The cleaning cycle is five minutes on average and consumables such as granulates, chemicals or water are not required. The system can be connected on Wi-Fi and has multiple pre-selected cleaning programs.

Lemorau has introduced the new finishing machine Smart-L, a semi-rotary die-cutter with upgrades and ‘smarter’ software. The die-cutter is servo driven, compact and has short web path.

MagVision has unveiled MagID, which uses patented marking technology to print unique codes onto labels that are covered up but remain readable. A MagID reader scans the label and connects to a cloud-based system that provides data for track and trace and authentication purposes. Originally developed by Inspectron, provider of secure document print technology, MagID is brought to market by spin-off MagVision. MagVision showcases how to add unique serialized codes at the set-up stage, giving every item its own unique, trackable identity. MagID uses barcodes printed in magnetic ink. The technology sits between RFID and visual barcodes. It is suitable for digitally printed labels and the application generates unique codes for each item. Tracking, authentication and product destination data is accessed via MagVision’s cloud-based management system. It is fully patented and backed by Horizon 2020 funding from the European Commission.

MagVision has unveiled MagID, which uses patented marking technology to print unique codes onto labels that are covered up but remain readable. A MagID reader scans the label and connects to a cloud-based system that provides data for track and trace and authentication purposes. Originally developed by Inspectron, provider of secure document print technology, MagID is brought to market by spin-off MagVision. MagVision showcases how to add unique serialized codes at the set-up stage, giving every item its own unique, trackable identity. MagID uses barcodes printed in magnetic ink. The technology sits between RFID and visual barcodes. It is suitable for digitally printed labels and the application generates unique codes for each item. Tracking, authentication and product destination data is accessed via MagVision’s cloud-based management system. It is fully patented and backed by Horizon 2020 funding from the European Commission.

Maxcess/RotoMetrics has unveiled its new RotoMetrics flexible die portfolio and supporting tooling products. New from Fife is a preview of its next-generation web guide, giving customers Industry 4.0 connectivity and smart data to automate processes. Componex has brought award-winning RotoRepel anti-stick coating to its line of Idler Rolls to help production run faster with less adhesive and ink build-up on the rolls. Also new is an Advantage series knife holder from Tidland.

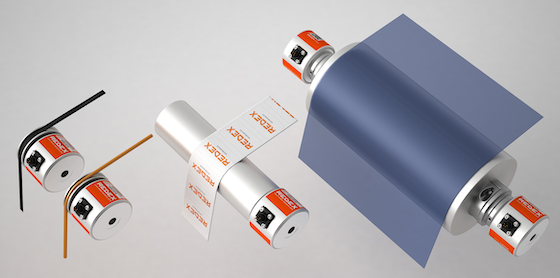

Merobel has introduced its new range of Redex Sensors to complete its portfolio of tension control technology. Redex WAT+ load cells introduce a modular architecture and can be mounted with pulley, roller or coupling. This flexibility offers to designers the capability to create their own accessories based on application or product specifications (shape, length, surface treatment). This concept addresses all types of materials with different widths from ribbon, narrow web and web applications.

Merobel has introduced its new range of Redex Sensors to complete its portfolio of tension control technology. Redex WAT+ load cells introduce a modular architecture and can be mounted with pulley, roller or coupling. This flexibility offers to designers the capability to create their own accessories based on application or product specifications (shape, length, surface treatment). This concept addresses all types of materials with different widths from ribbon, narrow web and web applications.

Miyakoshi has unveiled its newly designed semi-rotary offset label press, MEL. It is described by the company as an entry-level machine which inherits its high-level technology and printing quality from Miyakoshi’s MLP press. Included as standard are web cleaner, unit skewing, automatic ink roller washing, ink remote controller, numerical register control system, oscillating roller cooling system, die-cut with gap adjustment system and registration monitoring. The press can be customized with various process units and options for flexible usage.

Miyakoshi has unveiled its newly designed semi-rotary offset label press, MEL. It is described by the company as an entry-level machine which inherits its high-level technology and printing quality from Miyakoshi’s MLP press. Included as standard are web cleaner, unit skewing, automatic ink roller washing, ink remote controller, numerical register control system, oscillating roller cooling system, die-cut with gap adjustment system and registration monitoring. The press can be customized with various process units and options for flexible usage.

MPS has launched its seventh generation EF flexo press. The EF next-generation press is now equipped with the slide-out ink drawer as standard, E-Sleeves, improved Job Memory functionality and two automation levels. New to the press is the option of a wider 580mm web width. The MPSConnect platform combines sensor technology with the internet (IoT), meaning real-time data collection is possible from hundreds of events per second. This unbiased information helps to identify bottlenecks, errors, and inefficiencies to optimize press performance and decrease waste.

MPS has launched its seventh generation EF flexo press. The EF next-generation press is now equipped with the slide-out ink drawer as standard, E-Sleeves, improved Job Memory functionality and two automation levels. New to the press is the option of a wider 580mm web width. The MPSConnect platform combines sensor technology with the internet (IoT), meaning real-time data collection is possible from hundreds of events per second. This unbiased information helps to identify bottlenecks, errors, and inefficiencies to optimize press performance and decrease waste.

Pantec has launched the Cheetah N, a new machine system for applying 3D images to shrink sleeves with rotary hot foil technology. 3D images are available as customized designs. Logos or key visuals can be perfectly integrated into the design and become eye-catchers thanks to the 3D effect. Cheetah N applies up to 20 images per second at web speeds of up to 120m/min, enabling the commercial use of this innovative embellishing technique in the shrink sleeve sector.

Pantec has launched the Cheetah N, a new machine system for applying 3D images to shrink sleeves with rotary hot foil technology. 3D images are available as customized designs. Logos or key visuals can be perfectly integrated into the design and become eye-catchers thanks to the 3D effect. Cheetah N applies up to 20 images per second at web speeds of up to 120m/min, enabling the commercial use of this innovative embellishing technique in the shrink sleeve sector.

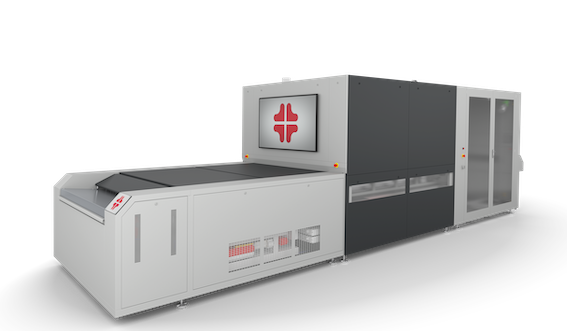

Polar has unveiled what it claims to be the fastest die-cutter on the market: LabelSystem DCC-12. It is designed for highly automated in-line production of bundled die-cut labels made of compressible plastic materials such as OPP-films for in-mold. The new control system enables a 25 percent increase in productivity, allowing the new DCC-12 to achieve an output of 10 cycles per minute. The new industrial control system enables modern alarm management, remote maintenance and diagnostics as well as integration into the digital workflow. The built-in servo technology improves process stability and increases downtime in production: the system runs more smoothly, and start and braking speeds can be set independently.

Polar has unveiled what it claims to be the fastest die-cutter on the market: LabelSystem DCC-12. It is designed for highly automated in-line production of bundled die-cut labels made of compressible plastic materials such as OPP-films for in-mold. The new control system enables a 25 percent increase in productivity, allowing the new DCC-12 to achieve an output of 10 cycles per minute. The new industrial control system enables modern alarm management, remote maintenance and diagnostics as well as integration into the digital workflow. The built-in servo technology improves process stability and increases downtime in production: the system runs more smoothly, and start and braking speeds can be set independently.

Premier Coating & Converters has introduced portfolios of self-adhesive materials. PremLaser covers laser printable materials and PremJet is its inkjet counterpart. Also new are sustainable, biodegradable and compostable options under the PremEco banner.

Premier Coating & Converters has introduced portfolios of self-adhesive materials. PremLaser covers laser printable materials and PremJet is its inkjet counterpart. Also new are sustainable, biodegradable and compostable options under the PremEco banner.

Rotutech Hispania has launched its new and improved Labelcut R30 coupled with the latest software LabelCutGo, optimizing workflow and enhancing job set-up. The blade finishing system based on Summa Vinyl Cutters is aimed at small and medium label production runs, allowing customization, versatility and flexibility.

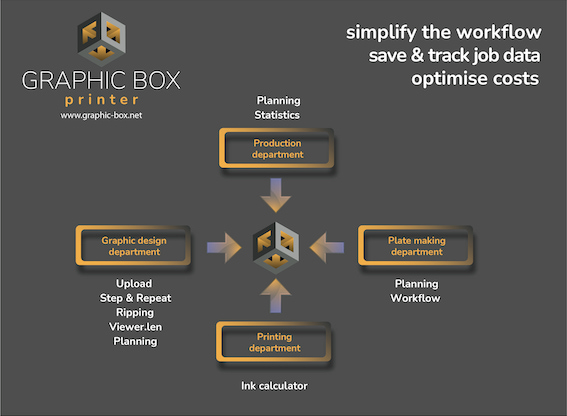

Side Graphics has previewed its new Graphic Box, consisting of a Graphic Box Web Printer and Graphic Box Web to Plate application. The Web Printer is an application aimed at label printers who integrate the production of their printing forms. It offers an optimized printing plate workflow with different accesses per log. It enables a graphic designer to upload the unit pose of his job and automatically produces the step and repeat followed by the ripping. A manufacturer can track the progress of all these orders on a listing and a manager can export statistics related to the drop rate and productivity. The Web to Plate application has been developed for tradeshops offering optimization of the workflow and production costs and expansion to new markets by providing a collaborative interface available online, an ERP with process progression and tracking number, an automatic step & repeat, .len verification, an online approval system, and a quote before validation, delivery note and online invoice.

Side Graphics has previewed its new Graphic Box, consisting of a Graphic Box Web Printer and Graphic Box Web to Plate application. The Web Printer is an application aimed at label printers who integrate the production of their printing forms. It offers an optimized printing plate workflow with different accesses per log. It enables a graphic designer to upload the unit pose of his job and automatically produces the step and repeat followed by the ripping. A manufacturer can track the progress of all these orders on a listing and a manager can export statistics related to the drop rate and productivity. The Web to Plate application has been developed for tradeshops offering optimization of the workflow and production costs and expansion to new markets by providing a collaborative interface available online, an ERP with process progression and tracking number, an automatic step & repeat, .len verification, an online approval system, and a quote before validation, delivery note and online invoice.

Steinbeis Papier has introduced a new wet and alkali resistant label paper, Steinbeis Label Wet, suitable for all common labels on beverage bottles and glass jars using wet gluing, hotmelt gluing and self-adhesive applications. It is printable by flexo and offset with excellent die-cutting properties. It is made from 100 percent recycled materials and – as with all recycled paper from Steinbeis – has been awarded the Blue Angel and EU Ecolabel. The company says the product is the result of a close investigation of the label paper market, where it realized its recycled paper is also suitable for processing into label papers. The result, Steinbeis Label Wet, is now a new product segment within the company’s portfolio of recycled papers.

Steinbeis Papier has introduced a new wet and alkali resistant label paper, Steinbeis Label Wet, suitable for all common labels on beverage bottles and glass jars using wet gluing, hotmelt gluing and self-adhesive applications. It is printable by flexo and offset with excellent die-cutting properties. It is made from 100 percent recycled materials and – as with all recycled paper from Steinbeis – has been awarded the Blue Angel and EU Ecolabel. The company says the product is the result of a close investigation of the label paper market, where it realized its recycled paper is also suitable for processing into label papers. The result, Steinbeis Label Wet, is now a new product segment within the company’s portfolio of recycled papers.

Synthogra has launched a new, fully recyclable synthetic paper, Syn-Strong LD. Optimized for printability in narrow web flexo, offset and digital printing, Synthogra’s synthetic papers are resistant to moisture, can be exposed to temperatures between 40 degrees below zero to 160 degrees Celsius and have high tear strength.

Synthogra has launched a new, fully recyclable synthetic paper, Syn-Strong LD. Optimized for printability in narrow web flexo, offset and digital printing, Synthogra’s synthetic papers are resistant to moisture, can be exposed to temperatures between 40 degrees below zero to 160 degrees Celsius and have high tear strength.

Taghleef has introduced its first bioPP and recycled film, designed to reduce fossil fuel depletion and contribute to a circular economy. Shape360 TDS, a full coverage label shrink film, confers a striking visual appeal to its containers without compromising recyclability, thanks to its floatability and easy separation. Also new is ReDesign, a project that aims to assist customers in finding the optimal and sustainable product to fit their needs.

TEG Technologies has expanded its Sitexco range of laser cleaners for anilox rollers with the new Sitexco Label. The L10 is designed for the narrow web sector and benefits from all the advantages of laser cleaning at the price of traditional technologies.

TEG Technologies has expanded its Sitexco range of laser cleaners for anilox rollers with the new Sitexco Label. The L10 is designed for the narrow web sector and benefits from all the advantages of laser cleaning at the price of traditional technologies.

Tootech has unveiled its new laser barcode label printer, TTE-72FK. The labels printed can't ever be erased because the printer prints on the middle layer of the material. It can print an area of up to 108mm(W) x 108mm(H) size of labels with the maximum resolution of 2,000 DPI.

Tootech has unveiled its new laser barcode label printer, TTE-72FK. The labels printed can't ever be erased because the printer prints on the middle layer of the material. It can print an area of up to 108mm(W) x 108mm(H) size of labels with the maximum resolution of 2,000 DPI.

Toyobo has introduced new products to help achieve more environmentally friendly production, such as Lesire, a laser-printable film for better recyclability; PET-D, a PET film for packaging and shrink sleeves with 50 percent PCR plastic content, obtained from PET bottles mechanically recycled in Japan; Reshine, a PET film for industrial use with 50 percent PCR PET content; Crisper and Kamishine, white, recycled PET films and anti-fog and easy-peelable PET sealant film.

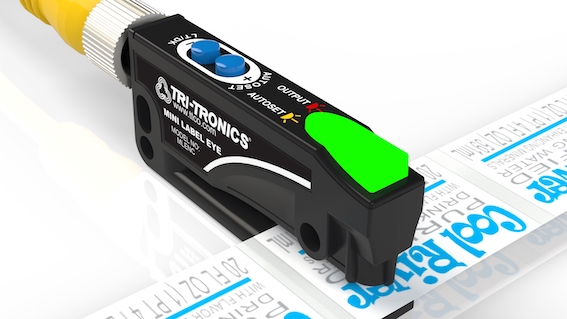

Tri-Tronics has launched its new Mini Label-Eye, a gap/slot sensor developed to detect labels on the web. For label applying, converting, printing and splice detection, the 10mm-wide sensor features a large LED indicator, one-touch Autoset with a response time of 35 microseconds for repeatability, which can be set from an HMI, and work on low voltage 4.75-30VDC.

Tri-Tronics has launched its new Mini Label-Eye, a gap/slot sensor developed to detect labels on the web. For label applying, converting, printing and splice detection, the 10mm-wide sensor features a large LED indicator, one-touch Autoset with a response time of 35 microseconds for repeatability, which can be set from an HMI, and work on low voltage 4.75-30VDC.

VPF has introduced a new product range for the durables sector, solid and durable adhesive materials for indoor and outdoor applications. The range consists of ten material combinations, some of which are UL-listed, seawater-resistant to BS5609, Sect. 2, and universally applicable for many technically demanding labeling tasks. Also new is a range of sustainable face materials and liners in addition to new grass papers, silphie papers, translucent papers, hemp papers or a paper made from recycled disposable coffee cups, complemented by innovative PE PP and PET films with high recycled content.

VPF has introduced a new product range for the durables sector, solid and durable adhesive materials for indoor and outdoor applications. The range consists of ten material combinations, some of which are UL-listed, seawater-resistant to BS5609, Sect. 2, and universally applicable for many technically demanding labeling tasks. Also new is a range of sustainable face materials and liners in addition to new grass papers, silphie papers, translucent papers, hemp papers or a paper made from recycled disposable coffee cups, complemented by innovative PE PP and PET films with high recycled content.

Wacker has unveiled new Dehesive eco products. The company replaced the methanol from fossil sources needed for manufacturing 100 percent with biomethanol from biomass such as straw and grass cuttings. It records the balance of biomethanol in its mix and mathematically allocates a portion of this to individual silicone products in proportion to the quantity of methanol used, an approach comparable to the green electricity certification system used in Germany. Dehesive eco and traditional Dehesive are chemically identical.

Wacker has unveiled new Dehesive eco products. The company replaced the methanol from fossil sources needed for manufacturing 100 percent with biomethanol from biomass such as straw and grass cuttings. It records the balance of biomethanol in its mix and mathematically allocates a portion of this to individual silicone products in proportion to the quantity of methanol used, an approach comparable to the green electricity certification system used in Germany. Dehesive eco and traditional Dehesive are chemically identical.

Zecher has launched an app for customers to manage their Zecher anilox roller park. Users can directly send requests for new anilox rollers, refurbishments or other Zecher products. A QR code scanner enables users to easily address claims.

Zecher has launched an app for customers to manage their Zecher anilox roller park. Users can directly send requests for new anilox rollers, refurbishments or other Zecher products. A QR code scanner enables users to easily address claims.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.