Digital Watermarks demonstrate effectiveness in HolyGrail 2.0 trials

Industrial trials on real post-household rigid packaging show detection efficiency ranged from 87.9 to 93.8 percent, consistently surpassing 90 percent.

The Digital Watermarks Initiative HolyGrail 2.0, driven by AIM and the European Brands Association and powered by the Alliance to End Plastic Waste (AEPW), has achieved a new milestone in its mission to demonstrate the viability of digital watermarking technology for accurately sorting plastic packaging at scale.

The latest trials, conducted at the Hündgen Entsorgung material recovery facility (MRF) in Swisttal, Germany, assessed the efficiency of digital watermarking applied to rigid household packaging collected in Germany and Denmark.

The facility, processing 100,000 tons of waste annually from three million households, was outfitted with detection prototypes and add-on modules co-developed by technology provider Digimarc and machine supplier Pellenc. These modules combined near-infrared (NIR) and digital watermark (DW) technology to improve sorting accuracy.

The trials took place from August 19 to December 19, 2024, aimed at evaluating sorting performance across various types and formats of packaging materials. The volumes of sorted materials were impressive, with detection rates averaging nearly 56,000 detections per day, totaling 5.66 million detections of 5,949 unique SKUs over the 100-day period. Detection efficiency ranged from 87.9 to 93.8 percent, consistently surpassing 90 percent through rigorous cloud-based analysis.

The trials focused on post-consumer rigid packaging waste across four different types and formats: PET non-food bottles, rigid PP, rigid PE (including tubes) and PET trays.

Participating companies Aldi, Arla Foods, Netto Marken-Discount, Haleon, Hochland, Mondelēz International, Orkla and Procter & Gamble had previously enhanced their SKUs with digital watermarks and placed them on the German and Danish market for consumer use, disposal and collection in designated areas.

The streams were further enhanced with additional quantities of digitally watermarked drinking cups from Coca-Cola and McDonald's, as well as tobacco canisters from Imperial Brands.

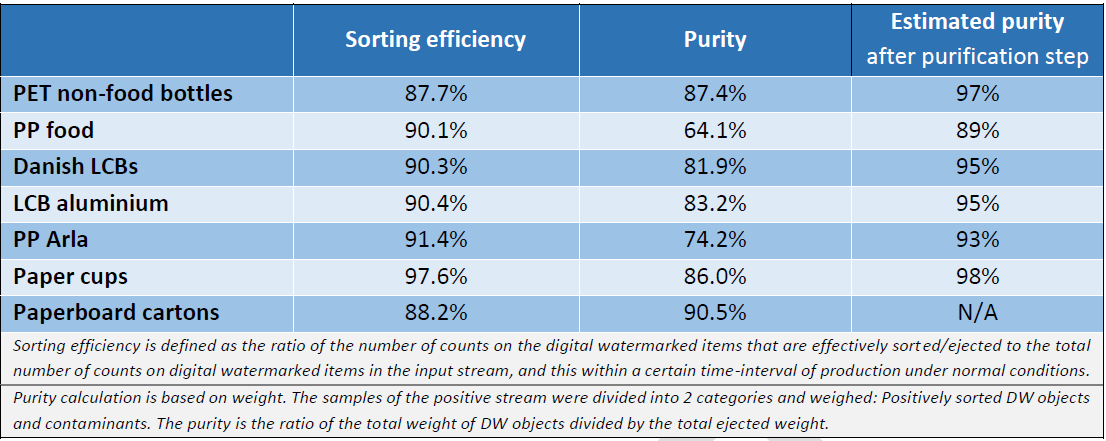

The results confirm that digital watermarking enables high-precision sorting, even under challenging industrial-scale conditions characterized by material overlap and dirty object surfaces. Two-pass sorting, as commonly applied in recycling facilities, is expected to further improve sorting efficiency and purity – as proven in previous HolyGrail 2.0 sorting trials.

The trial confirms the potential of digital watermarks for accurately sorting post-consumer rigid household packaging, achieving 90 percent and higher sorting efficiency even under challenging real-world conditions and single-pass sorting.

While results were obtained from a single-pass sorting, they are expected to improve in industrial settings with additional processing, proving the technology’s readiness for full commercial deployment. Besides the accuracy and unlike current industrial sorting technologies, digital watermarks also enable an unprecedented level of granularity, reaching SKU-level sorting.

These findings mark a significant step forward in adopting intelligent detection and sorting. The trials demonstrated that Digimarc digital watermarking technology can facilitate traceability of packaging waste at the SKU level, providing a pathway to compliance with the Packaging and Packaging Waste Regulation (PPWR), most notably the recycled content requirements for plastic packaging set to become applicable as of January 1, 2030.

With the conclusion of HolyGrail 2.0, the focus now shifts to market adoption programs under the HolyGrail 2030 – Circular Packaging initiative. The objective will be to prove the economic viability of smart sorting and reprocessing into high-quality recyclates, that can be used again in packaging applications, including food packaging, for all packaging chain stakeholders.

Early-adopter market demonstrations will be launched in Belgium (for flexible PP food packaging) and Germany (for rigid PP food packaging), with the objective of further scaling the technology and allowing participants access to dedicated recycled PP food-grade materials.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.