Labelexpo Americas 2024: Ancillary technology

Ancillary exhibitors at Labelexpo Americas 2024 showcased RFID equipment, sustainability and much more. Crystal Lindell reports

New and improved RFID labeling equipment, small-batch printing tools and sustainable technology were among the trends for ancillary technology exhibitors at this year’s Labelexpo Americas 2024.

"Although RFID technology has been around fro many years, the recent use of RFID for inventory tracking and security on a large scale is relatively new"

Ancillary suppliers also were focused on offering increased operator friendliness and improved software capabilities at the show, as well as stronger hardware upgrades.

Suppliers respond to RFID

Walmart has been leading the push for companies to include RFID in its labeling. The move could revolutionize both the checkout process and inventory management, but it also requires big changes from its suppliers.

Many of the ancillary exhibitors at this year’s show offered innovative technologies to companies looking to integrate RFID tags into their labeling.

Buskro showed RFID-DLP1085, which integrates printing, personalization and tracking in a single seamless process. Engineered for fast, reliable label production to meet demanding schedules, it includes built-in RFID capabilities to enhance tracking and inventory management.

BW Papersystems highlighted multiple manufacturing technologies for the RFID industry with its T-165 manufacturing platform, which is made for the entire value chain of RFID production. The highly modular system ensures accurate RFID inlay placement, register lamination of multiple layers of paper or foil, rotary die cutting and other relevant supplementary processes. The available features also include chip data encoding and tag personalization.

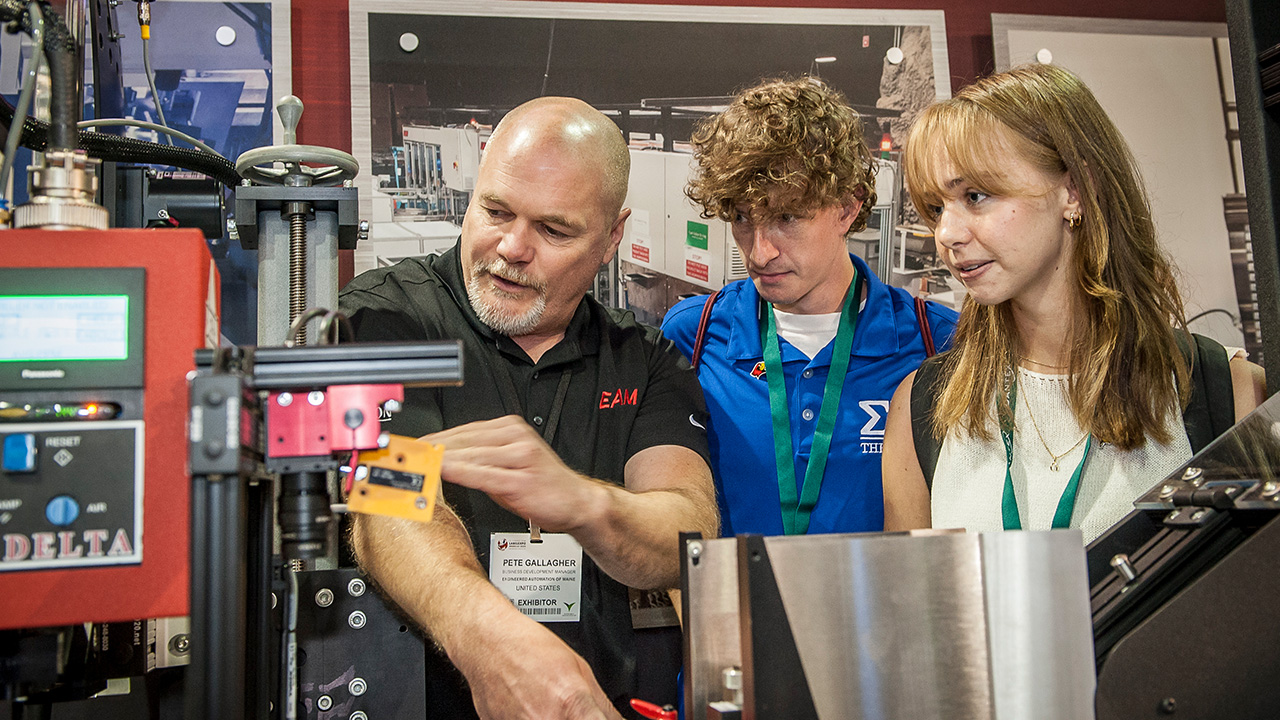

EAM featured Wipe-on RFID labeling machines, which included custom labeling and part handling, high-speed application rate capability and a small integration footprint.

‘Although RFID technology has been around for many years, the recent use of RFID for inventory tracking and security on a large scale is relatively new,’ the company says. ‘We work directly and cooperatively with EAS and RFID label manufacturers to improve our equipment and their label manufacturing processes to bring the end customer the best EAS and RFID solutions.’

Kirk-Rudy showed multiple RFID technologies as well, one of which was the KR 519 label and encoding RFID system, able to apply RFID labels and encode them in one machine. Offering UHF Gen II RFID chip pipeline coding, its high-reliability camera reads 1D, 2D barcodes and OCR.

Rosas Maschinenbau, which exhibited with Graph-Tech USA, showed RFID label converting on the Leopard 300 rewinder. The equipment is a bidirectional tabletop rewinder that features an advanced RFID HF and UHF tag serialization module with code verifier and backside serialization and a TIJ printer for numbering and coding. This technology encodes and verifies RFID tags at high speeds.

Voyantic showed Tagsurance 3 quality control system. Both modular and scalable, it’s a complete system for measuring the performance of UHF and HF RFID inlays, tags and labels in different stages of the production process, from chip attachment to label converting and incoming inspection.

Sustainable, energy-efficient products

Sustainable and energy-efficient products were also popular at this year’s Labelexpo Americas, as exhibitors showed off both the environmental benefits and the potential for cost savings.

Coast Controls featured a pneumatic all-air system web guide. Based on a proportional All-Air Servo Control, which operates entirely on low-pressure plant air, the Servo Controller works with an Airflow sensor, so it uses no electricity and offers pinpoint accuracy as well as dependability.

"Our goal is to minimize downtime and ensure that your operations run smoothly and efficiently"

Flexo Wash highlighted anilox laser cleaning machines under its FW 850 line. The waste-free systems clean the rolls without water or chemicals. And the company has made improvements to the system that makes it faster.

Eaglewood Technologies showcased Bella - Model DC-1300, certified for HP Indigo digital presses. The company says it’s the most thorough, environmentally-friendly and cost-effective method for cleaning all critical press components. Ink tanks, application rollers, etc are cleaned efficiently with HP specific imaging oil. The integrated recycling system continuously removes the HP imaging oil from ink particles. As a result, operating costs and the volume of hazardous waste are reduced to a minimum.

Excelitas featured Phoseon Nexus One UV LED curing systems with an expanded UV LED curing platform for flexographic printing. The company highlighted the fact that the Nexus One water-cooled products are now available in six sizes, including 300mm, 375mm, 450mm, 525mm, 600mm and 675mm. According to the company, the new systems deliver 38 percent more energy with 90 Watts per 25mm LED array segment.

GEW launched AeroLED2 at the show, which features an efficient optical design that enables the lowest energy usage of all GEW products.

AeroLED2 is a next-generation, higher-power UV LED system for full cure, printing, coating and converting applications up to 70cm wide; AeroLED2 offers a 30 percent increase in electrical power (70W/cm), a 30 percent increase in UV dose (170mJ/cm2) and a 40 percent increase in UV irradiance (26W/cm2) compared to its predecessor, AeroLED.

AeroLED2 is also ArcLED compatible. Using the same fan and ducting arrangement as the industry standard E2C, customers have total flexibility to switch between UV arc and AeroLED2 on any station. This delivers energy savings of up to 55 percent compared to a conventional UV arc system. In fact, two AeroLED2 systems have a lower electrical supply requirement than just one conventional arc UV system.

Kongskilde Industries showed a live set-up of its Kongskilde CUB All-in-One Unit trimmer. Tailored for label converting, film extrusion, coating and lamination, slitting and rewinding, printing, and packaging production lines, the versatile, compact unit handles various types of waste, including adhesive and non-adhesive trim, easily moving between machines. It transports trim up to 35m and disposes of it into a 900-liter bag. The machine’s energy-efficient radial ventilator means it also has low energy consumption.

LaserClean showcased sustainable anilox cleaning machines at this year’s show. The company launched ALCS800 machine, equipped with the latest laser cleaning technology for narrow and mid-web. The machine offers an eco-friendly alternative to traditional anilox cleaning methods, reducing waste and minimizing environmental impact.

Lundberg Tech showcased MatrixCompactor 200, a waste-capturing system designed specifically for label matrix handling. This system helps to reduce the use of virgin materials and lower the CO2 footprint associated with the transport of waste. Additionally, it minimizes the unnecessary disposal of paper cores and alleviates the physical strain on press operators by reducing heavy lifting requirements.

Ox Industries showcased a selection of 100 percent uncoated, recycled paperboard and customer-converted paper products, including tube and core grades. The company originally purchased recycled material from nearby paper mills, but in 2007 it opened its own paper mills across the United States so that it could control the entire process. Now, with five paper mills across the country, they offer their paper products from 100 percent recycled materials.

Tootech featured a laser label printer, TTE-72FK. Printing underneath the laminated layer onto the middle layer prevents erasing from wear or friction. And it’s designed to create no-ribbon waste, making it eco-friendly.

Meanwhile, Tower Products, a manufacturer of environmentally sensitive pressroom chemistry for the offset and flexographic printing industry, launched a new adhesive cleaning product, SmartFlex Adhesive Remover.

Developed for use on plate cylinders in the flexographic and offset pressroom, it features a low-odor formula that cleans the adhesive without any damage to the photopolymer plate, plate cylinder or any machinery. The formula also does not contain any toxic ingredients and has a very high flashpoint to enhance workplace safety. Further solidifying its eco-friendly status, it’s also sold in an easy-to-use recyclable quart container.

Inspection equipment

Inspection equipment continues to improve as companies make faster, more precise machines that also make it easier to identify mistakes before they spin out of control.

Erhard + Leimer showcased a web monitoring system, ELScan OMS5. Featuring DualView technology with 2 x 18 megapixels for magnificent image quality, it also has a motorized crossbeam with precise, high-speed control.

The unique LED-based flash concept works for all types of printing, and it offers straightforward system integration due to the new quick alignment function.

It has Autoscan functions, digital repeat overview with fast navigation and a position gallery with 21 saved positions. It also offers master image comparison in different variants, DeltaE color monitoring, detection of stripe defects, image stabilization, automatic job change detection and the ability to archive repeat orders.

E+L also featured 200 percent inspection system, Smartscan, designed for printing and finishing machines for narrow-web applications. It offers continuous double inspection of the entire width and length of the web, and can detect print defects, missing labels, unremoved matrices, splice points, flags, color defects, damage and more.

Re USA showcased ReVision Net, an integrated web viewing and control system. From a single control point, with up to two touch displays, operators have access to any number of ultra-compact, high-quality cameras. The system offers a large field of view and captures still details with 16 times zoom, even at high web speeds.

TKM showed Enpurex Ecoline Cleaning Wipes, which can be used for hand and surface cleaning. They can remove even coarse soiling such as paint, varnish, grease, oil, glue, wax, soot, permanent markers, ballpoint pens, grease and board markers. The wipes are also characterized by their skin-friendly and moisturizing effect and are pH-neutral.

Unilux unveiled a collaboration with GlobalVision to provide on-demand press proofing. It will provide the printers with the ability to compare the print quality to a master proof on-press using industry standards for barcode grading and delta color.

High-definition images captured by UniPrint are transferred to GlobalVision press proofing software for analysis on-demand. Operators are alerted of changes in quality in real time and empowered to make corrections before the run is complete.

Advances in software

Ease-of-use was also a theme at this year’s expo. Several ancillary exhibitors showcased new, more operator-friendly equipment, software upgrades and machines.

Brodbeck Maschinenbau featured Multi ID Core Cutter UNI 1000, a machine with the patent-pending design of a single-cutting mandrel suitable for all core diameters between 25 and 180 mm.

Once the desired cutting length and quantities are keyed in and the parent tubes fed in, the machine cuts and discharges cores without additional setup, making it operator-friendly.

Digital Print introduced the M7, a 13-in variable system operating at speeds over 800ft/min with a resolution of up to 600 DPI, printing variable barcodes, text and graphics.

The M7 is designed for efficiency and precision, optimizing ink usage and minimizing downtime.

The M713-in system offers user-friendly operation and maintenance. The system can print widths of over 26in and be configured to print duplex jobs. It also comes in a double-bar configuration that can run twice the speed and resolution of a standard single-bar system.

Double E Group was exhibiting with its partner Dotec Roll Handling, showing equipment that was sure to make a lot of operators’ lives easier. The company’s roll handlers mean that operators no longer have to manually lift large, heavy rolls. Instead, its machines can lift it for them. Designed for control, easy operation, and optimal ergonomic use, the line makes work both easier and more enjoyable.

GoDEX International unveiled thermal printing technologies, which integrate with popular printer languages such as EZPL, GEPL, GZPL, GDPL and come with free label and tag design software that supports database integration. GoDEX’s showcase is headlined by the GX4600i, a 600 DPI thermal printer boasting a 5in video touchscreen LCD with built-in video-assisted guidance, as well as a one-touch calibration button.

"Many of the ancillary exhibitors at this year's show offered innovative solutions to companies looking to integrate RFID tags into their labeling"

Graymills featured Printclean HP Indigo edition parts washer, which was designed with assistance from experts at HP. Built to operate with HP’s imaging oil, it features an extra-long, stay-put flexible metal flush hose for directed hands-free flushing action. It also has a permanently mounted flow-thru brush for detailed cleaning and adjustable bi-level work shelves. There’s also a safety lid that closes to reduce fluid evaporation and shuts automatically in case of fire.

MFT Automation showcased a 12in Impresso Labeler and Feeder System featuring 300-millimeter width capability. Its three-piece shaft allows for easy belt changeover, and its brushless servo motor allows for accurate placement.

The self-contained computer controls offer an on-board panel designed to easily interface with existing computers, PLC, or other host machinery.

MoistTech featured moisture measurement sensors, which provide an accurate and reliable near-infrared system, increasing efficiency, quality control and consistency while eliminating rework, waste and human error from time-consuming lab methods. The result is an almost instant ROI.

QC Electronics launched newly redesigned electrode assemblies designed to make operation, maintenance, and service more straightforward. New features include lifting shroud covers on both ceramic and metal assemblies, optimized electrode keys on our metal assemblies, fresh new features on the controls, and more, all designed with the end user in mind.

Rigaku Technologies presented the NEX LS, an in-line silicone coatings analyzer for real-time process control. NEX LS serves roll-to-roll applications and allows continuous monitoring of the process from start to finish without stopping production. NEX LS software features an analytical head that sweeps back and forth across a moving web, as real-time data displays as a graphical cross-direction and machine-direction profile. This helps silicone coaters make immediate quality control decisions to achieve a targeted laydown and ensure release properties or barriers are not compromised.

Sonic Solutions showcased Phoenix Line of equipment, which features the company’s traditional systems but is upgraded with several enhancements that make it easier to use. Featuring a safer level of ultrasonics, it uses 68 kHz to allow smaller bubbles to get into the smaller cells of the higher line count rolls.

It also has modified power generators, which are now external, interchangeable and easily replaceable.

Start International showed LR4500 bidirectional label rewinder, which rolls labels onto a roll core as they are dispensed from a thermal transfer printer or reel. The label rewinder operates in two directions, forward and backward. It also has two speeds, slow and fast. Two LR4500 label rewinders can be used to unwind and rewind labels for the proper orientation of labels.

Doctor blades and anilox rolls

Exhibitors at this year’s show also highlighted advances in hardware, including doctor blades, anilox rolls and engraving equipment.

Flexon featured Swed/Cut highly refined, micro structured carbon, stainless, and coated steel doctor blades. They eliminate print defects, minimize waste and downtime, boost production speeds, and enhance performance, all while protecting your bottom line. The range of high-quality carbon, stainless and coated steels known for its micro-refined structures and slow, even edge wear.

Fuji Shoko featured ceramic doctor blades, which last longer, meaning they don’t have to be changed as often. That results in less downtime. Ceramic Doctor Hi-Blade is the company’s highest-quality ceramic-coated model, offering excellent resistance against wear and abrasion. Our special ceramic coating improves the wiping quality and blade life.

Harper Corporation featured its Xtreme Channeled Application Technology (XCAT).

The XCAT engraving has a combination of consistent pocket structures that create a channel flow, acting like a closed cell channel without ink sag. It also makes the anilox easier to clean and can reduce or eliminate scoring by allowing particles to pass through rather than being trapped behind the blade.

The XCAT has been designed to maintain the optimization in artwork running on traditional 60-degree engravings and is suitable for ink spitting, ghosting, scoring, foaming, ink re-solubility at high speeds, and maintaining plate angles and speed.

Interflex Laser Engravers featured Blömker Hybrid Sleeves that use the same technology as the original sleeve design; they also feature a stronger-than-steel, carbon-fiber technology inner cord that makes them 20-25 percent lighter than the standard sleeve. It also allows for tighter tolerances and less deflection.

They work best with wide web applications where high-speed printing requires improved rigidity and balances tolerances together.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.